Why Epoxy Resin Manufacturers in Pakistan Are Driving Industrial Growth

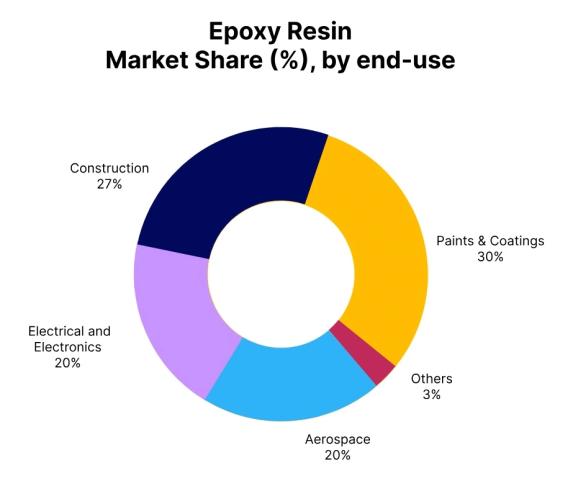

Epoxy resin has become a key material in industries ranging from construction and flooring to electronics and art. Its versatility, durability, and chemical resistance make it highly valuable in both industrial and creative applications. With demand rising every year, epoxy resin manufacturers in Pakistan are stepping into the spotlight, creating products that meet global standards while addressing local market needs.

How Epoxy Resin Manufacturers in Pakistan Are Evolving Rapidly

The global demand for advanced adhesives, coatings, and composites has grown significantly, and the Pakistani market is following the same trend. Manufacturers in the region are focusing on:

-

Industrial applications such as flooring, adhesives, and protective coatings.

-

Consumer products like resin art, jewelry, and DIY projects.

-

High-performance sectors including electronics, automotive, and construction.

By aligning with global technology, epoxy resin manufacturers in Pakistan are not only catering to domestic industries but also contributing to exports.

The Role of Epoxy Resin in Modern Industries

Epoxy resin is not just another material—it plays a vital role in strength, safety, and aesthetics across multiple fields.

-

Construction: Used in tile bonding, waterproofing, and concrete repair.

-

Flooring: Offers chemical resistance, glossy finishes, and long life in industrial and residential spaces.

-

Electronics: Protects sensitive components from heat, dust, and moisture.

-

Automotive & Aerospace: Provides lightweight yet strong bonding materials.

This diverse usage explains why epoxy resin manufacturers in Pakistan are scaling production and investing in research.

Growth Opportunities for Epoxy Resin Manufacturers in Pakistan

As industries demand more eco-friendly and efficient solutions, local producers are responding with innovation. Key opportunities include:

-

Water-based epoxy resins to reduce environmental impact.

-

High-performance adhesives for infrastructure development.

-

Resin systems for creative industries, tapping into the growing resin art community.

-

Smart material development, focusing on UV resistance and fast-curing systems.

These developments give local manufacturers the ability to compete with international players while strengthening the domestic market.

Challenges Faced by Manufacturers

Like any growing industry, challenges exist. Some of the most pressing issues for epoxy resin manufacturers in Pakistan include:

-

Access to advanced raw materials.

-

Rising production costs due to energy and logistics.

-

Need for higher awareness among small-scale industries.

-

Competing with imported resins at lower prices.

However, many manufacturers are tackling these problems through technology adoption, strategic partnerships, and R&D.

Why Businesses Choose Local Epoxy Resin Producers

-

Affordability compared to imported resins.

-

Customization for specific applications like flooring, adhesives, or potting compounds.

-

Faster availability with reduced lead times.

-

Support for local economy and industries.

This makes local epoxy resin suppliers a strong option for businesses looking for cost-effective yet high-quality solutions.

Future Outlook of Epoxy Resin Industry

The future looks promising. As infrastructure projects, industrial growth, and resin-based crafts expand, the demand will rise even further. By 2030, analysts expect exponential growth in the epoxy resin market in South Asia, with Pakistan playing a central role.

With increasing investment, better technology, and skilled manpower, epoxy resin manufacturers in Pakistan are set to become vital players in the regional and global supply chain.

FAQs

Q1: What industries use epoxy resin the most?

Epoxy resin is widely used in construction, flooring, automotive, electronics, marine, and creative art industries.

Q2: Are epoxy resin products durable?

Yes, epoxy resins are known for their strength, chemical resistance, and long-lasting finish, making them ideal for demanding applications.

Q3: How do epoxy resin manufacturers in Pakistan compete globally?

They focus on quality, affordable pricing, technological innovation, and adapting to the unique requirements of both local and international markets.

Q4: Is epoxy resin eco-friendly?

Traditional epoxy resins are petroleum-based, but new eco-friendly and waterborne options are being developed to reduce environmental impact.

Q5: Why is epoxy resin popular in flooring?

It provides a seamless, glossy finish, resists chemicals and abrasion, and has a longer lifespan compared to conventional flooring solutions.

Visit here for more Informational blogs at promoteproject.