Step into any modern office, lively restaurant, or stylish home studio, and you’ll sense more than just visual appeal. You’ll hear the difference. The air carries a calm, intentional quiet. Echoes that once bounced off bare walls have been replaced with a soft, balanced ambiance. Behind this shift isn’t just clever design, but an innovative material reshaping how we experience sound: recycled plastic bottles.

What is it All About?

Polyethylene Terephthalate, better known as PET, has quietly taken center stage in the world of acoustics, becoming a favorite among architects, interior designers, and sustainable builders. Its rise isn’t a coincidence.

PET acoustic panels bring together three forces driving modern spaces: exceptional sound performance, a commitment to environmental responsibility, and unmatched creative freedom.

More than a product, PET panels represent a forward-thinking approach to how we shape our surroundings. This is where functionality, sustainability, and >

Why Do Acoustic Panels Exist?

At their core, acoustic panels exist to control sound. PET panels excel in this fundamental task through their unique physical composition. The material is essentially a dense matrix of curled and crimped polyester fibers, creating a labyrinth of microscopic air pockets.

When sound waves hit the surface of the panel, they penetrate this fibrous jungle rather than bouncing off. As the energy from the sound waves tries to navigate this complex path, it encounters immense friction and is converted into negligible amounts of heat, effectively dissipating the noise.

This mechanism, known as sound absorption, is what tackles issues like reverberation and echo. PET panels are exceptionally effective across a wide frequency range, from the high-pitched clatter of dishes to the low rumble of conversation. This broad-spectrum performance makes them incredibly versatile, suitable for everything from dampening the roar in a gymnasium to ensuring vocal clarity in a conference room.

As one audio engineer noted, “The goal is not to create a dead space, but an intelligible one. PET panels absorb the noise that muddies communication, leaving behind a clean, clear sonic environment.”

Choosing Sustainability as a Standard

In an era where environmental responsibility is no longer a bonus but an expectation, PET panels carry a powerful narrative. The vast majority of high-quality PET acoustic products are manufactured from post-consumer recycled plastic, primarily the very bottles we recycle every day. This process diverts substantial waste from landfills and oceans, giving a second life to a durable, non-biodegradable material.

The sustainability story doesn’t end with recycled content. The production process for creating polyester fiber from recycled PET is significantly less energy-intensive than manufacturing virgin acoustic materials like fiberglass or foam. Furthermore, many PET panels are themselves fully recyclable at the end of their long lifespan, contributing to a circular economy.

This powerful eco-credential allows designers to meet stringent green building standards like LEED and BREEAM without compromising on acoustic performance. “We’re no longer just designing spaces; we’re making a statement about values,” says a leading interior designer. “Choosing a material that is performative, beautiful, and planet-positive is the new benchmark.”

A Designer’s Dream: Unmatched Aesthetic Versatility

Performance and sustainability would mean little if the product were an eyesore. This is where PET panels truly separate themselves from traditional options. Their fibrous nature is inherently malleable, allowing them to be compressed into an almost limitless array of forms and finishes.

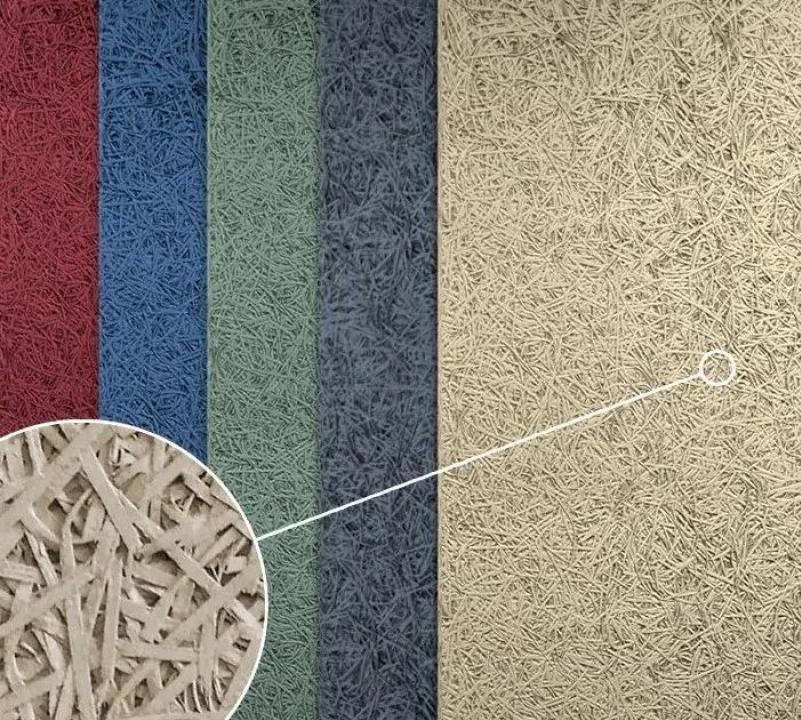

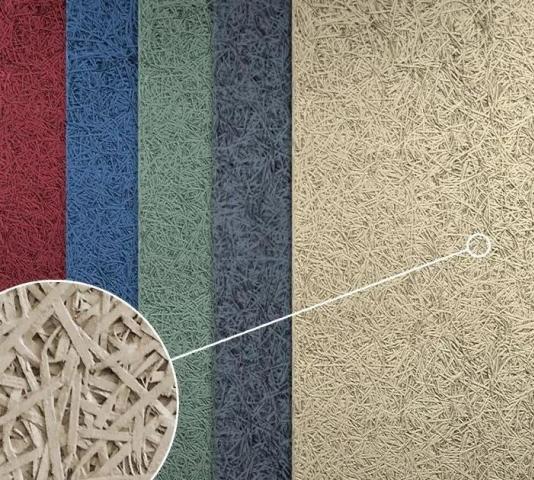

Color and Form

They can be dyed in a vast spectrum of colors during the manufacturing process, meaning the hue is consistent throughout the entire depth of the material. This allows for creative shapes, beveled edges, and dramatic curves without revealing an unfinished core. From organic, cloud-like formations to crisp, geometric tiles, the design possibilities are boundless.

Application Flexibility

These panels can be specified as straightforward wall-mounted boards, suspended from ceilings as elegant baffles or clouds, or even fashioned into free-standing space dividers. The ‘PET panel ceiling’ has become a particularly popular solution in open-plan offices, where it quietly soaks up ambient noise while defining the visual landscape of the workspace.

Tactile and Visual Texture

The surface can range from a smooth, felt-like finish to a more textured, almost fabric-rich appearance. This adds a layer of tactile warmth that is often missing from cold, hard building materials.

Built to Last: Durability and Practicality

Beyond the initial installation, a material must stand the test of time. PET panels are renowned for their robustness. They are highly resistant to moisture and humidity, meaning they will not warp, sag, or foster mold and mildew growth in environments where traditional fabric-wrapped panels might fail. This makes them ideal for use in swimming pool enclosures, restaurants, and even some exterior applications.

Maintenance is another key advantage. Their non-porous surface means they do not easily trap dust, allergens, or odors. Most cleaning requires only a quick vacuuming with a brush attachment or a gentle wipe with a damp cloth. This low-maintenance characteristic is a critical benefit for high-traffic commercial spaces where hygiene and long-term upkeep are constant considerations.

The Complete Package: A Value Proposition

When all these factors are considered, the value proposition of PET panels becomes undeniable. While the initial cost may be comparable to or slightly higher than some conventional materials, the total cost of ownership is often lower.

Their longevity and minimal maintenance needs reduce long-term expenses, while their aesthetic appeal can directly contribute to the perceived value and branding of a commercial space.

Is it a Fleeting Trend Then?

In conclusion, the ascent of PET acoustic panels is no fleeting trend. It is a logical response to the demands of modern construction and design. They successfully address the tripartite challenge of achieving exceptional acoustic performance, fulfilling environmental responsibilities, and enabling stunning visual creativity.

By transforming a ubiquitous waste product into a high-performance design element, PET panels have not just joined the conversation on acoustic treatment; they have decisively shaped it, establishing themselves as the top-tier material for creating healthier, quieter, and more beautiful spaces for everyone.