In today’s competitive manufacturing landscape, the term “precision” has evolved from a differentiator into a necessity. Across sectors automotive, aerospace, renewable energy, infrastructure the ability to fabricate metal components with minute accuracy, consistency, and speed is driving a new generation of industrial capability. Precision metal fabrication is no longer an optional capability; it’s central to the next wave of innovation.

What Precision Metal Fabrication Means

Metal fabrication traditionally meant cutting, bending, welding and assembling raw metal into functional parts and structures. While those processes still apply, precision metal fabrication brings a higher level of fidelity: tighter tolerances, better surface finishes, complex geometries, and repeatability across large volumes or bespoke runs. It’s a fusion of advanced tooling, digital design, data control and materials science.

This elevated level of fabrication is critical because modern manufactured products demand ever-better performance. Whether it’s lighter vehicle components to boost fuel efficiency, stronger structural elements for large builds, or compact, high-tolerance assemblies for electronics and healthcare equipment—fabrication must deliver more than just function; it must deliver excellence.

Key Technologies Behind the Shift

Several technologies have converged to enable precision fabrication. First, computer numerical control (CNC) machines allow tools to move with high accuracy and repeat the same operation hundreds or thousands of times without variation. Whether milling aluminium blocks or turning steel shafts, the digital control enables new levels of consistency.

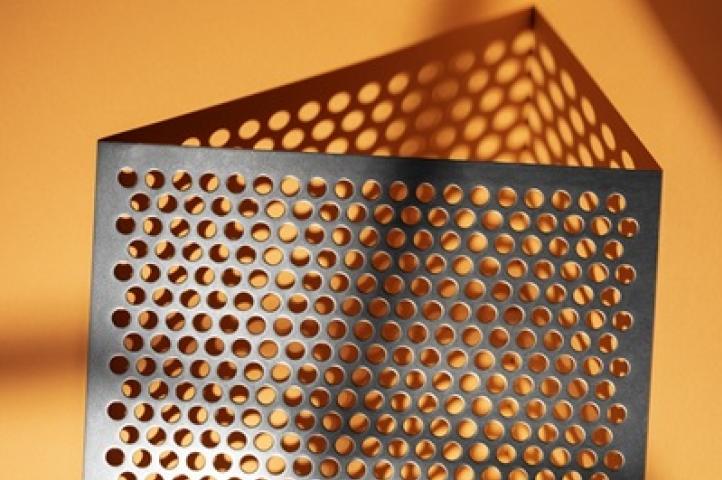

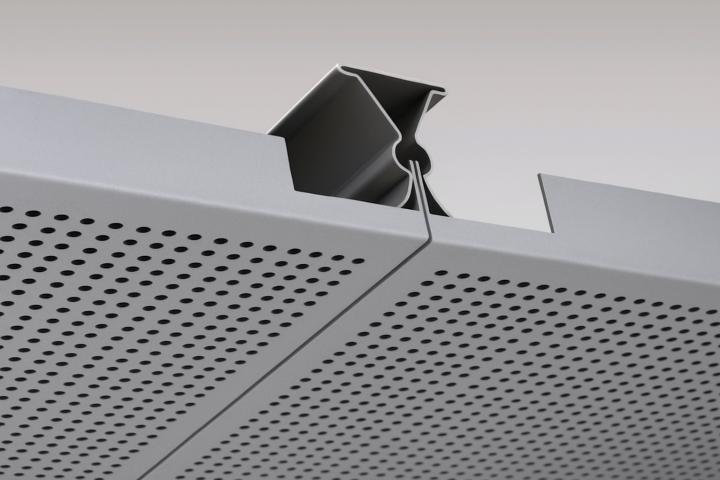

Next, laser cutting and water-jet or plasma systems allow sheet metal and structural profiles to be shaped rapidly with minimal distortion and high edge quality. Complex patterns, intricate cut-outs and high throughput are now standard, not exceptions.

Then comes automated welding and robotic assembly systems, which no longer rely purely on human dexterity. Sensors, vision systems and feedback loops ensure that welds meet exact specifications, avoid rework and deliver joint strength consistently.

Finally, digital twin, simulation and IoT monitoring tie the whole process together. Fabrication operations are no longer isolated workshops; they feed data into connected factory systems, allowing engineers to refine tool paths, predict maintenance needs, monitor quality in real time and reduce waste dramatically.

Why It Matters for Industry

Precision metal fabrication is doing more than improving one part it’s enabling entire systems to evolve. Here’s why this matters:

Faster innovation cycles: With high-precision tools and digital workflows, prototypes move to production more quickly. One can iterate design, test, refine and fabricate within shorter timeframes.

Cost-effectiveness through scalability: While higher precision might suggest higher cost, in many cases it reduces waste, rework and production downtime. More consistent first-time passes mean parts require less manual correction, and that saves labour, material and time.

Enabling advanced materials and lightweighting: Many new applications demand lighter weight and high strength—aluminium alloys, titanium, high-strength steels. Precision fabrication allows reduced wall thickness, optimized shapes and minimal margins, which is essential for aerospace, transport and renewable energy.

Improved reliability and quality: In sectors where failure is not an option (e.g., medical implants, air-frame components, offshore structures), fabrication must meet strict standards. Precision methods ensure that every weld, cut and finish is within tolerance, which improves durability and performance.

How Fabricators Are Adapting

Fabricators are transforming their operations in response to this demand. The following approaches stand out.

Investment in smarter machinery: Fabrication shops are upgrading from manual or semi-automated equipment into high-precision CNC, robotic welding cells and automated handling systems. This often involves a higher upfront cost, but the payoff comes through long-term productivity and reduced labor dependency.

Digital workflow integration: CAD and CAM tools tie directly into fabrication equipment. Designs move seamlessly from engineer to machine. Simulations catch issues before metal is cut. Data from fabrication is captured and fed back into design cycles to continually refine the process.

Modular manufacture and flexible production: Precision fabrication enables smaller batch sizes, custom runs, and quick changeovers. This flexibility is essential in markets where demand shifts quickly or where products require customization.

Quality systems and traceability: Digital monitoring means each part can have a recorded fabrication history cutting parameters, weld settings, finishing data. That traceability is increasingly required in regulated industries and serves as a differentiator for fabrication providers.

Impact Across Sectors

Precision metal fabrication is making visible impacts in many industrial sectors.

Automotive: Fabricated brackets, frames and components are becoming lighter, stronger and more cost-effective, enabling electric and hybrid vehicle designs to advance.

Aerospace: High-tolerance parts, built with minimal excess material and assembled with precision, reduce weight and improve performance for aircraft and satellites.

Renewable energy: Wind towers, solar mounting systems and storage enclosures benefit from large-scale fabricated metal structures that must perform reliably in harsh conditions.

Infrastructure and smart buildings: Fabricated metal is essential in modular construction, prefabricated building systems and large architectural installations precision ensures fit, finish and durability.

Healthcare and electronics: Specialised frames, housings and structural parts for medical devices rely on fabrication capabilities that can handle delicate finishes and tight tolerances.

Challenges and the Future

Despite its clear benefits, precision fabrication also faces challenges. Some of these include.

Material cost fluctuations: High-strength alloys and exotic materials cost more, driving pressure on margins. Fabricators must optimize tool paths, minimize scrap and improve yield to absorb these costs.

Skilled labour shortages: While automation reduces manual tasks, expertise is still required in programming, setup, simulation and system oversight. Training remains a critical factor.

Integration complexity: Implementing connected workflows that tie CAD-CAM systems to shop-floor machinery and IoT sensors requires investment, change management and software ecosystems.

Sustainability and energy use: Fabrication machines still consume significant energy. As customers and regulators demand greener operations, providers must find ways to reduce carbon footprints, recycle metals and adopt cleaner energy sources.

Looking ahead, innovations such as adaptive manufacturing, where machine tools adjust in real time based on sensor feedback, and hybrid additive-subtractive fabrication, where 3D printed metal components are finished by precision machining, will shape the next generation of fabrication services. Digital twins will enable simulation of entire fabrication workflows before metal enters the machine, reducing error and time to market even further.

Conclusion

Precision metal fabrication is more than machining or welding—it underpins the competitiveness of modern manufacturing. Companies that can deliver accurate, flexible and high-quality fabricated components have a strategic advantage in an industrial world increasingly defined by speed, customization and sustainability.

For any business looking to stay ahead in sectors like automotive, aerospace or infrastructure, finding a fabrication partner that offers both technological depth and operational agility is vital. In effect, precision metal fabrication is not just a service; it’s a capability that fuels industrial innovation.