A team of BTech CSE second-year students from KLH Aziznagar, a constituent of KL University has developed an innovative QR-based digital identification system for Indian Railways track fittings, offering a smarter alternative to the traditional paint and stamped-number approach that often fades and becomes unreliable over time.

Indian Railways uses lakhs of clips, bolts, clamps, fishplates and other fittings across thousands of kilometres. These components are critical to safe operations, yet inspectors frequently struggle to trace their installation details or maintenance history because existing markings wear out. This slows down inspections and makes it harder to identify defective or missing parts in time.

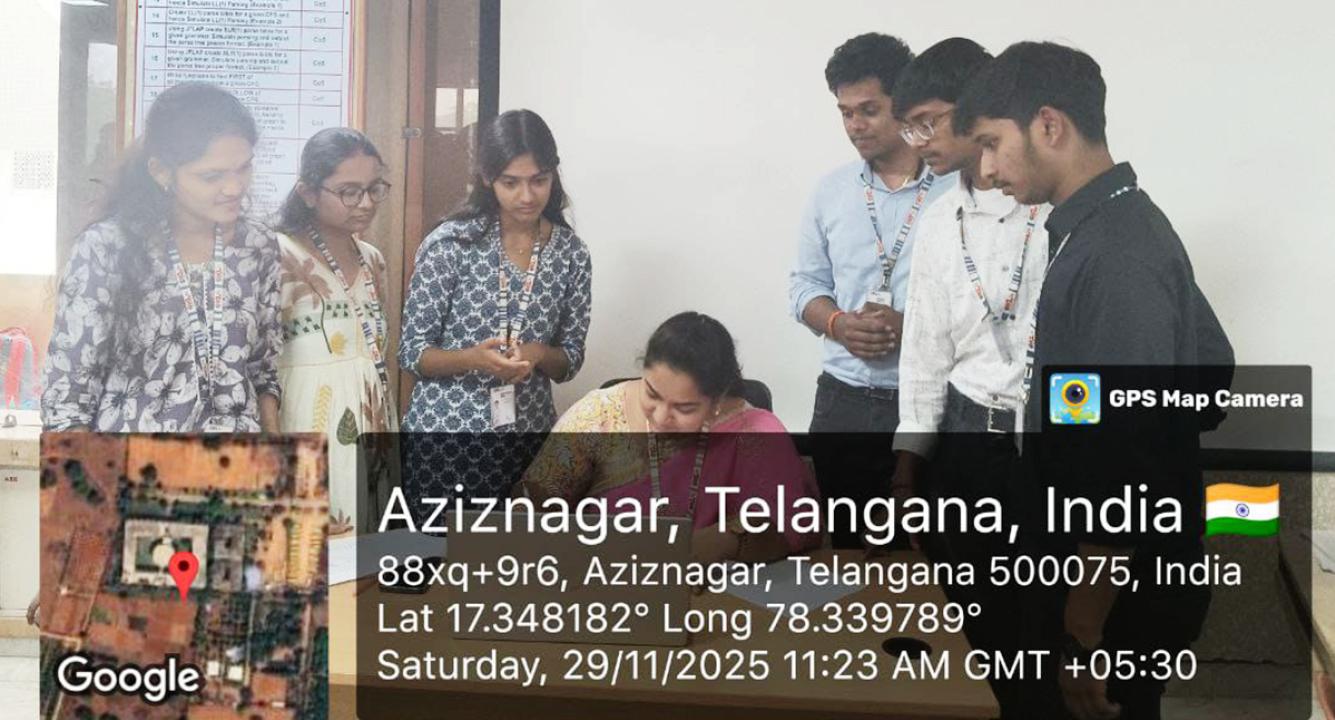

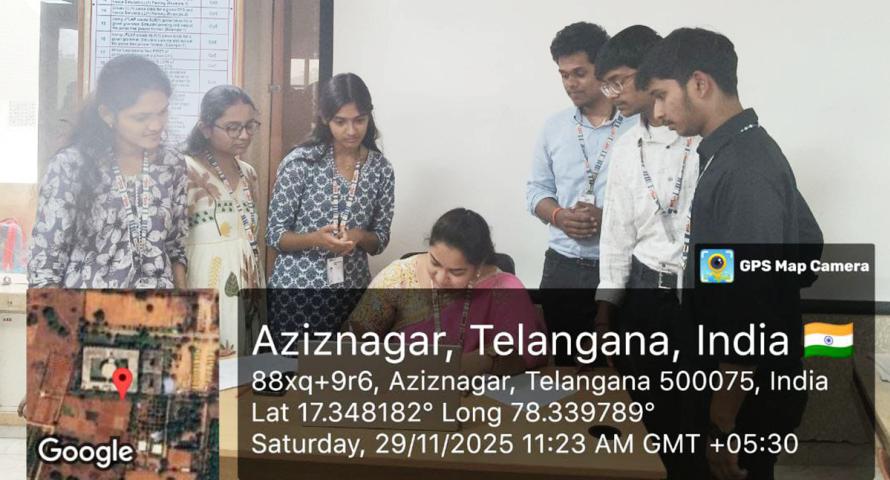

The KLH student team, Bhavya Praneetha Vemuri, S Alekhya Reddy, Harshitha Reddy, V Srimukh Sai Sharan, M Vamshidhar Reddy and S Narendhar, under the guidance of mentor Saidi Reddy, created an end-to-end solution that assigns every fitting a permanent digital identity.

At the heart of their system is a laser engraving module controlled by a microcontroller or Raspberry Pi. New or refurbished fittings are placed in a holder, assigned a unique ID, and engraved with a durable QR code. A dedicated database of engraving parameters helps ensure the code remains clear on different metal surfaces without damaging the material.

The QR code stores only the compact ID, while all other information is stored securely in a central digital database. This includes manufacturer details, fitting type, batch number, installation date, location and complete maintenance history. A web dashboard gives railway engineers quick access to search functions, inspection records and automated reports that reveal trends in faults or performance.

To support field teams, the students also developed an Android application that lets track staff scan a fitting on-site and instantly view its details. Inspectors can update its condition, add photos and sync data when connectivity allows. The app is currently progressing through the software execution stage, where features are being refined for deployment.

This project shows how thoughtful engineering can improve day-to-day operations in large public systems. It also reflects the practical, problem-solving mindset nurtured at KL University places it among the best universities in India for hands-on, innovation-led learning.

The QR-based solution highlights what young technologists can achieve when they bring curiosity and real-world thinking together, offering a promising model for smarter and more efficient railway maintenance in the future.