Have you ever noticed small stickers on product packaging that say things like “Inspected,” “QC Passed,” or “Quality Approved”? These simple stickers are known as quality control labels, and while they may look small and unimportant, they actually play a huge role in keeping products safe, reliable, and trustworthy.

From manufacturing floors to retail shelves, quality control labels quietly work behind the scenes to make sure products meet the right standards before reaching customers. Let’s explore what they are, how they’re used, and why they matter so much—without any complicated jargon.

What Are Quality Control Labels?

Quality control labels are stickers or tags placed on products, packaging, or components after they’ve passed a quality inspection. They show that an item has been checked and approved based on specific quality standards.

These labels typically include information such as:

- Inspection status (approved, rejected, or pending)

- Date of inspection

- Inspector’s initials or code

- Batch or lot number

- Special handling instructions

In simple terms, quality control labels act as visual proof that quality checks have been completed.

Why Are Quality Control Labels Important?

Quality control labels matter because they:

- Prevent defective products from reaching customers

- Improve workplace efficiency

- Build brand trust

- Support regulatory compliance

- Reduce costly errors and returns

They help businesses maintain consistency and accountability throughout the production and distribution process.

How Quality Control Labels Work in Real Life

Let’s imagine a simple example.

A company manufactures kitchen appliances. Each product goes through several quality checks before packaging. After final inspection, a quality control label is applied to show that the item meets safety and performance standards. This label ensures that warehouse workers, shipping teams, and retailers know the product is approved for sale.

Without quality control labels, there would be confusion, delays, and a much higher risk of faulty products reaching customers.

Different Types of Quality Control Labels

Not all quality control labels look the same. They vary based on industry, product type, and quality requirements.

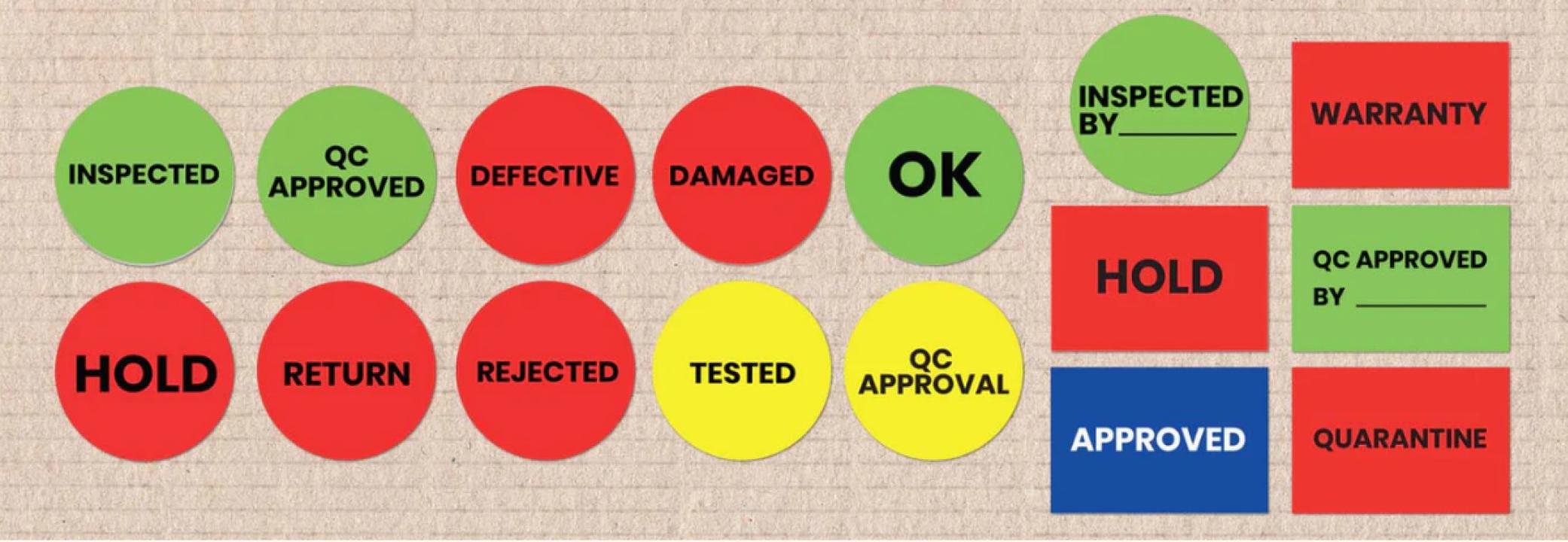

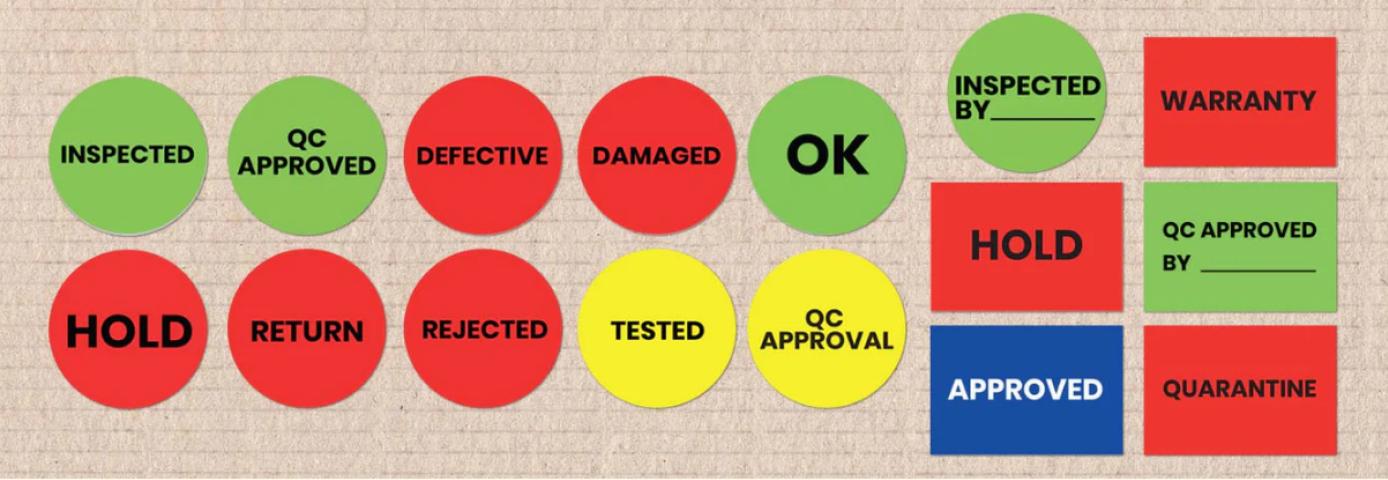

Some common types include:

- Approved / Passed labels

- Rejected / Hold labels

- Inspected labels

- Tested labels

- Date-coded labels

- Color-coded quality labels

Each type plays a specific role in guiding product handling and movement.

Where Are Quality Control Labels Used?

Quality control labels are widely used across industries, including:

- Manufacturing

- Food and beverage

- Pharmaceuticals

- Electronics

- Automotive

- Warehousing and logistics

- Retail packaging

No matter the industry, quality control labels help ensure product reliability and customer safety.

How Quality Control Labels Improve Product Safety

One of the most critical roles of quality control labels is protecting customers.

They:

- Prevent faulty items from being sold

- Identify inspected batches

- Ensure compliance with safety regulations

- Reduce risk of recalls

In industries like food, medicine, and electronics, quality control labels are essential for public safety.

Boosting Efficiency in Operations

Quality control labels don’t just improve safety—they also improve efficiency.

By clearly marking product status, they:

- Reduce confusion

- Speed up inventory movement

- Minimize handling errors

- Simplify warehouse workflows

This helps businesses save time, reduce labor costs, and improve overall productivity.

Building Customer Trust Through Quality Control Labels

Customers may not always notice quality control labels, but their impact is powerful.

Knowing that products are inspected and approved builds:

- Brand credibility

- Customer confidence

- Repeat business

Over time, consistent quality supported by clear labeling helps brands earn long-term loyalty.

Supporting Regulatory Compliance

Many industries operate under strict regulations. Quality control labels help document inspection processes and prove compliance during audits and inspections.

They provide:

- Traceability

- Inspection records

- Proof of testing

This is especially important in regulated sectors like healthcare, food production, and automotive manufacturing.

How Quality Control Labels Reduce Costly Mistakes

Even small errors in production can lead to:

- Product recalls

- Customer complaints

- Warranty claims

- Brand damage

Quality control labels act as checkpoints, catching issues early and preventing expensive mistakes later.

Designing Effective Quality Control Labels

An effective quality control label should be:

- Easy to read

- Visually clear

- Durable

- Well-placed

Common design elements include:

- Bold text

- Clear color coding

- Simple layouts

- Strong adhesive

This ensures quick recognition across production and logistics teams.

Choosing the Right Material for Quality Control Labels

Durability is key. Depending on usage, labels may need to withstand:

- Heat

- Moisture

- Chemicals

- Friction

- Outdoor conditions

That’s why selecting the right label material matters. Strong adhesives and weather-resistant materials ensure labels stay readable and intact throughout the product lifecycle.

Digital Tracking and Smart Quality Control Labels

Modern quality control labels often include:

- Barcodes

- QR codes

- Serial numbers

These allow companies to track products digitally, improving traceability, transparency, and data accuracy.

Common Mistakes to Avoid

Some common quality labeling mistakes include:

- Poor visibility

- Weak adhesive

- Incomplete information

- Inconsistent placement

Avoiding these ensures your quality control labels perform their role effectively.

Why Every Business Should Use Quality Control Labels

Whether you’re a small startup or a large manufacturer, quality control labels help create structure, accountability, and consistency.

They support:

- Smooth workflows

- Better product quality

- Improved customer experience

In today’s competitive market, businesses that prioritize quality stand out—and labels play a big part in that.

Final Thoughts

Quality control labels may seem small, but their impact is enormous. They ensure products are safe, reliable, compliant, and trustworthy. They streamline operations, reduce mistakes, and protect brand reputation—all while creating confidence for customers.

In short, quality control labels are one of the simplest yet most powerful tools for maintaining excellence in product manufacturing and distribution.

Looking for durable, custom quality control labels that meet industrial standards and boost operational efficiency? Choose high-quality labeling solutions designed for real-world performance—only from StickerJet.