The die attach machine market is experiencing consistent growth driven by the rapid expansion of the semiconductor and electronics manufacturing industries worldwide. Die attach machines play a critical role in semiconductor packaging by precisely placing and bonding semiconductor dies onto substrates or lead frames. These machines are essential in ensuring electrical performance, thermal conductivity, and long-term reliability of electronic components. Increasing demand for compact consumer electronics, electric vehicles, advanced computing systems, and IoT devices is significantly influencing the adoption of automated die attach equipment across global manufacturing facilities.

Manufacturers are focusing on enhancing machine accuracy, automation integration, and throughput efficiency to meet the growing demand for high-performance chips. Technological advancements such as AI-assisted vision alignment, multi-die placement capabilities, and hybrid bonding methods are further accelerating market expansion. The market continues to evolve with rising investments in semiconductor fabrication plants and packaging innovations across developed and emerging economies.

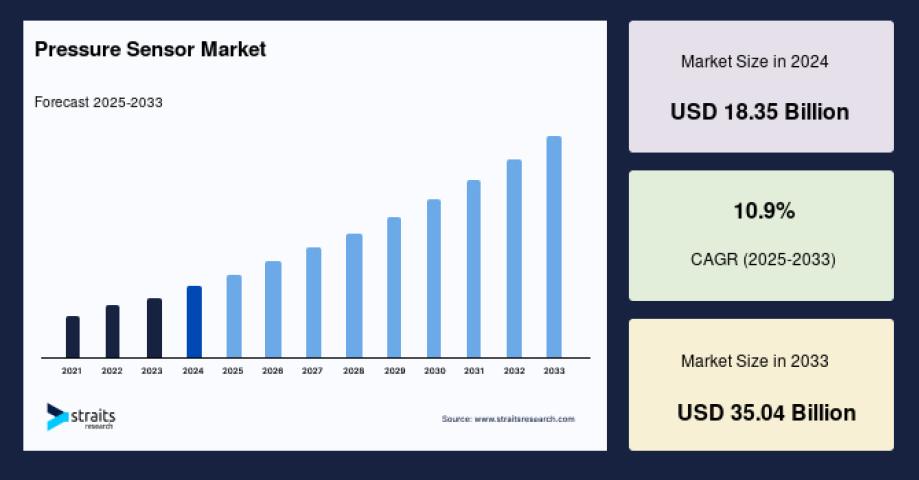

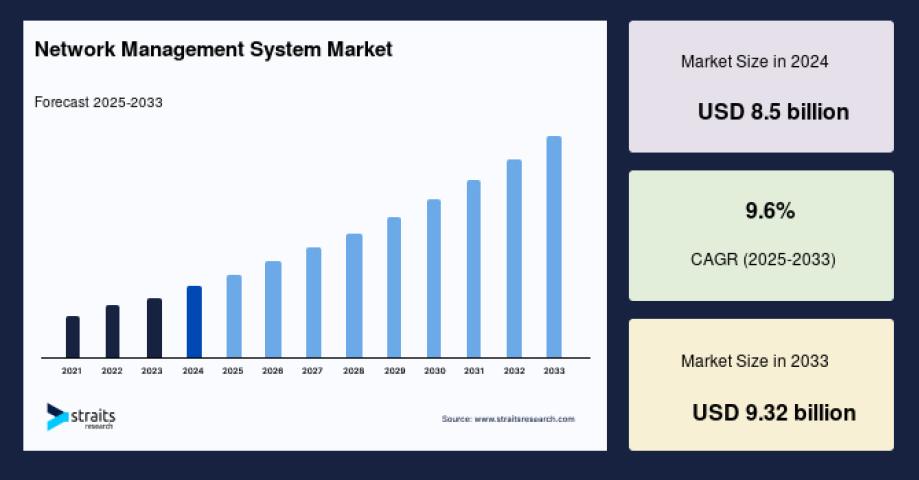

Market Size

The global die attach machine market size was valued at USD 1.47 billion in 2024. It is projected to grow from USD 1.56 billion in 2025 to USD 2.54 billion by 2033, exhibiting a CAGR of 6.3% during the forecast period (2025-2033).

Market Dynamics

Market Drivers

Growing Semiconductor Industry Expansion

The increasing production of semiconductors across multiple industries is a primary growth driver. Consumer electronics, automotive electronics, telecommunications, and industrial automation sectors are heavily dependent on semiconductor devices. The expansion of fabrication plants and outsourced semiconductor assembly and test facilities is directly boosting demand for advanced die attach machines.

Rising Demand for Miniaturized Electronic Devices

The global shift toward smaller and more powerful electronic devices is encouraging manufacturers to invest in precision bonding equipment. Smartphones, wearable devices, laptops, and smart home technologies require compact chip designs, which intensifies the need for high-accuracy die placement systems.

Automation and Industry 4.0 Adoption

Integration of robotics, machine vision, and AI-based quality control is transforming semiconductor packaging operations. Automated die attach machines reduce operational errors, enhance production speed, and minimize labor costs, making them a preferred choice among large-scale electronics manufacturers.

Electric Vehicle and Renewable Energy Growth

Electric vehicles and renewable energy infrastructure require advanced power semiconductor modules. Die attach machines are crucial for assembling high-power chips used in battery management systems, inverters, and charging solutions, contributing to long-term market growth.

Get Your Sample Report Here: https://straitsresearch.com/report/die-attach-machine-market/request-sample

Market Challenges

High Initial Investment Costs

Advanced die attach systems involve significant capital expenditure, which can limit adoption among small and medium-sized enterprises. The cost of maintenance, software upgrades, and skilled labor training further increases operational expenses.

Technological Complexity

Rapid technological evolution requires constant upgrades and technical expertise. Manufacturers must continuously adapt to new packaging methods and bonding technologies, which can be challenging for companies lacking R&D capabilities.

Supply Chain Disruptions

Fluctuations in semiconductor supply chains and geopolitical tensions can impact production cycles and equipment procurement. Delays in raw material availability and logistics constraints pose risks to steady market growth.

Market Segmentation

By Machine Type

Fully Automatic Die Attach Machines

Fully automatic machines dominate the market due to their ability to handle high-volume production with minimal human intervention. These machines offer advanced vision alignment, rapid die placement, and superior bonding accuracy, making them ideal for large semiconductor fabrication facilities.

Semi-Automatic Die Attach Machines

Semi-automatic machines are widely used by mid-scale manufacturers and research facilities. They provide flexibility and lower investment costs compared to fully automated systems while still ensuring acceptable precision and production efficiency.

By Bonding Technique

Eutectic Bonding

Eutectic bonding is commonly used for high-reliability semiconductor applications. It provides excellent thermal and electrical conductivity, making it suitable for aerospace, defense, and power electronics industries.

Epoxy Bonding

Epoxy bonding remains popular due to cost-effectiveness and ease of application. It is widely adopted in consumer electronics and general semiconductor packaging processes.

Soft Solder Bonding

Soft solder bonding is utilized for power devices and applications requiring strong mechanical strength and heat resistance. This technique supports high-temperature operations and extended durability.

By Application

Consumer Electronics

This segment holds a major share due to continuous product launches and device upgrades. Smartphones, tablets, laptops, and wearable devices rely heavily on efficient semiconductor packaging technologies.

Automotive Electronics

Advanced driver assistance systems, electric vehicles, and infotainment systems are significantly increasing semiconductor consumption, thereby driving die attach machine demand.

Industrial and Telecommunications

Industrial automation equipment and telecommunications infrastructure require reliable semiconductor modules, supporting steady growth in this segment.

By End User

Integrated Device Manufacturers

These companies manufacture semiconductors in-house and invest heavily in advanced packaging technologies to maintain competitive advantage.

Outsourced Semiconductor Assembly and Test Providers

OSAT providers represent a rapidly growing segment as many semiconductor companies outsource packaging and testing operations to specialized service providers.

Access the Complete Die Attach Machine Market Research Report Today: https://straitsresearch.com/buy-now/die-attach-machine-market

Top Players Analysis

The die attach machine market is characterized by the presence of global equipment manufacturers focusing on technological innovation, automation, and precision engineering. Competitive strategies revolve around research and development investments, partnerships with semiconductor fabrication companies, and expansion into high-growth Asian markets. According to Straits Research analysis, leading players emphasize machine speed optimization, advanced bonding technologies, and integrated inspection systems to strengthen their market presence.

Continuous product innovation and multi-die bonding capabilities are central competitive strategies.

Strategic collaborations with semiconductor foundries enhance long-term equipment supply agreements.

Investment in AI-powered vision systems improves accuracy and defect detection efficiency.

Expansion of regional service centers strengthens after-sales support and customer retention.

Adoption of sustainable and energy-efficient manufacturing designs is emerging as a competitive differentiator.