In the world of mechanical motion, Gas Spring (pneumatic spring) has become a core component in industrial manufacturing and daily life, thanks to its stable thrust and intelligent buffering characteristics. As a research and development focus of Colewell, Gas Spring provides efficient solutions for automotive, furniture, medical, and other scenarios through precise pneumatic control technology. This article will deeply analyze its application scenarios to help you understand the broad value of this technology.

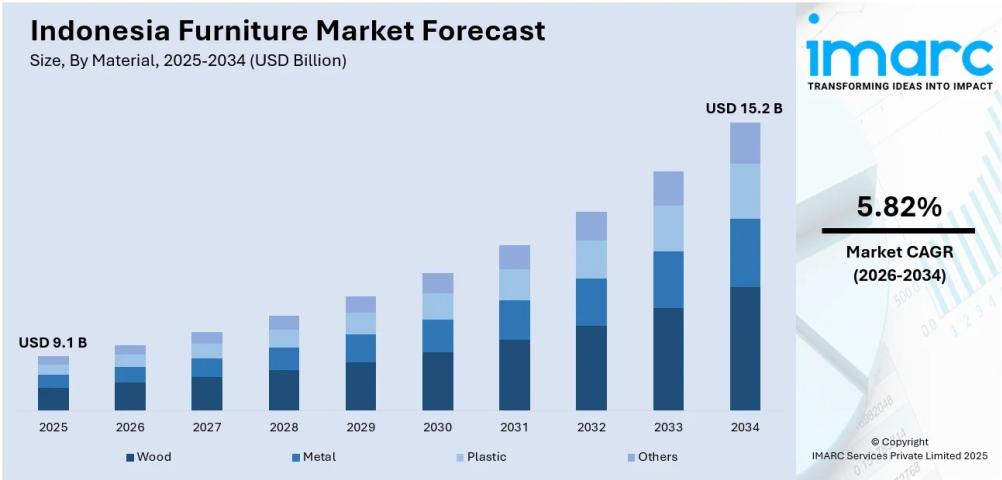

Furniture Industry: Key Components Enhancing Ergonomics

Intelligent Adjustment of Furniture Gas Spring

In furniture design, Furniture Gas Spring achieves stepless adjustment through pneumatic drive. For example:

Lifting office chairs: Built-in Gas Lift supports precise adjustment of seat height to relieve fatigue from prolonged sitting;

Cabinet flip doors: Paired with a damping system to achieve slow closing of door panels, preventing pinching and extending hinge life.

Multi-Scenario Adaptation of Lockable Gas Spring

Devices such as medical beds and household folding tables rely on the locking function of Lockable Gas Spring. Its features include:

Stepless hovering: Fixed load at any position within the stroke via button or cable control;

High locking force design: Locking force can exceed 10,000N during medical bed adjustment to ensure patient safety.

Automotive Industry: Engineering-Level Guarantees for Safety and Convenience

Core Applications of Car Gas Strut

In the automotive field, Car Gas Strut (automotive gas stay) achieves efficient support through nitrogen pressure difference:

Intelligent tailgate control: Supports stepless hovering and anti-pinch function to avoid sudden closing risks;

Hood protection: Equipped with a damping system to ensure slow opening during maintenance and improve operational safety.

Adaptation Innovations for New Energy Vehicles

For electric vehicle battery compartment lids, Gas Spring must pass corrosion-resistant coating and extreme temperature tests (-40°C to +80°C) to meet lightweight and durability requirements.

Industrial Equipment: Essential Needs in Heavy-Duty and Precision Scenarios

Safety Support for Heavy-Duty Machinery

In construction machinery and stamping equipment, Heavy Duty Gas Spring can provide up to 400,000N of thrust for:

Machine tool protective covers: Resisting high-frequency vibrations to ensure operational safety;

Automated production lines: Balancing the lifting of heavy components to reduce motor load.

Precision Control in Medical Equipment

Key applications of Lockable Gas Spring in the medical field include:

Operating table angle adjustment: Supports multi-dimensional precise positioning with an error of less than 0.5mm;

Imaging equipment lifting: Adopts a silent design to avoid interfering with precise detection.

Four Standards for Selecting a Gas Spring Manufacturer

Customization capability: Flexible design based on parameters such as load, stroke, and installation angle;

Durability verification: Passed 30,000-cycle fatigue tests to ensure zero leakage and long service life;

Environmental adaptability: Corrosion-resistant coatings withstand salt spray, acid, and alkali environments;

Safety certifications: Compliant with standards such as IATF 16949 (automotive) and ISO 13485 (medical).

Conclusion: Colewell – Your Professional Gas Spring Partner

As a technology brand deeply rooted in precision manufacturing, Colewell provides full-scenario solutions from Furniture Gas Spring to Heavy Duty Gas Spring according to engineering-level standards. Our products undergo rigorous testing and support customized development to help you achieve safe and efficient mechanical control.

For technical parameters or customized services, please contact the Colewell team. We will empower your projects with professional capabilities.