Introduction

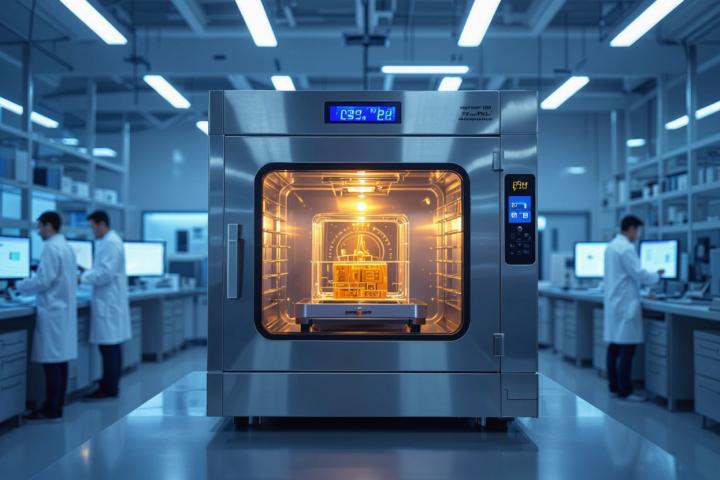

Global demand for faster, safer, and higher-quality food production is pushing manufacturers to embrace advanced technologies. Among these, robotics in food industry has emerged as a game-changer. From automated packaging to quality inspection, robots are helping companies stay competitive while meeting stringent hygiene and safety standards.

Why Robotics is Essential in Food Manufacturing

Unlike traditional production methods, robots bring speed, consistency, and adaptability to food manufacturing. They not only reduce human intervention but also ensure compliance with strict health guidelines, making them a vital investment for modern factories.

Core Applications of Robotics in Food Industry

1. Automated Packaging

Robots handle boxing, wrapping, labeling, and palletizing at unmatched speeds, cutting down packaging time and errors.

2. Pick and Place Operations

From biscuits and chocolates to frozen foods, robots pick items off the line and place them accurately into trays or cartons.

3. Sorting and Quality Assurance

Robots equipped with vision systems identify defects and ensure only the best-quality items move forward.

4. Processing Tasks

Slicing, cutting, mixing, and portioning tasks are performed with consistency, improving uniformity across batches.

5. Hygiene-Sensitive Operations

In industries like dairy, seafood, and meat, robots reduce direct human handling, improving hygiene and safety.

Benefits of Using Robotics in Food Industry

- Higher Productivity – 24/7 operation with consistent performance.

- Improved Accuracy – Uniform packaging and portion control.

- Labor Savings – Robots reduce dependence on manual work in repetitive tasks.

- Safety Compliance – Lower contamination risks through minimal human contact.

- Flexibility – Robots can adapt to new product lines and seasonal demands.

Robotics and Sustainability in Food Industry

Modern food robotics is designed with sustainability in mind. They use less energy, minimise material wastage, and support eco-friendly packaging initiatives. This helps manufacturers meet both operational efficiency and green goals.

Challenges in Adopting Food Robotics

While the advantages are clear, businesses should be aware of:

- High initial investment in automation systems.

- Training requirements for operators and maintenance staff.

- Integration challenges with existing production lines.

With the right partner, these challenges can be minimised, and ROI can be achieved faster.

Delta Stark Engineering: Your Food Robotics Partner

At Delta Stark Engineering, we deliver customized robotics solutions for the food industry that focus on efficiency, compliance, and reliability.

Our robotics offerings include:

- Pick and Place Robots

- Packaging & Palletizing Robots

- Vision-Based Sorting Systems

- End-of-Line Automation

We understand the unique challenges of food manufacturers in India and provide tailored solutions that enhance production efficiency while meeting hygiene standards.

Conclusion

The role of robotics in food industry is no longer optional—it’s essential. With growing consumer demand and strict regulatory requirements, automation ensures safe, high-quality, and cost-efficient food production. Partnering with experts like Delta Stark Engineering helps manufacturers embrace this transformation with confidence.