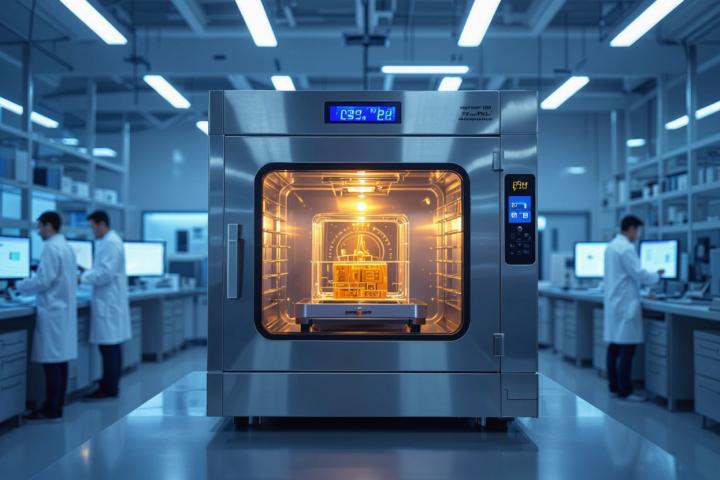

In an era where speed, precision, and cost-effectiveness define manufacturing success, injection moulding robots have become indispensable. These advanced machines automate key aspects of the plastic injection process, ensuring high-quality production while reducing human labor and errors.

What Are Injection Moulding Robots?

Injection moulding robots are automated systems designed to handle tasks such as:

-

Removing finished parts from the mould

-

Loading inserts into moulds

-

Sorting and stacking components

-

Assisting in quality control

By automating these repetitive and often hazardous tasks, manufacturers can maintain consistency, improve safety, and increase throughput.

Why Manufacturers Are Choosing Robots

1. Increased Productivity

Robots work continuously, completing repetitive tasks faster than human operators. By shortening cycle times and reducing downtime, production efficiency increases significantly.

2. Superior Product Quality

Robots offer precision and repeatability that humans cannot match. This ensures uniformity in parts, reduces defects, and minimizes waste.

3. Enhanced Safety

Handling molten plastic and high-pressure machines is risky. Robots remove human operators from dangerous tasks, reducing workplace accidents.

4. Long-Term Cost Savings

Though the upfront investment may be high, robots lower labor costs, scrap rates, and machine wear. Over time, the return on investment (ROI) is substantial.

5. Flexibility and Scalability

Modern robots are programmable for different part sizes, materials, and production volumes, making them suitable for industries ranging from automotive to medical devices.

Types of Injection Moulding Robots

-

Cartesian Robots: Move along X, Y, Z axes; ideal for straightforward pick-and-place tasks.

-

Articulated Robots: Multi-jointed arms for complex handling and multi-angle access.

-

SCARA Robots: Fast, precise lateral movements suitable for repetitive operations.

-

Delta Robots: Lightweight, high-speed handling of small parts, commonly used in packaging.

Applications Across Industries

-

Automotive: Bumpers, dashboards, and interior components.

-

Medical: Syringes, containers, and precision devices.

-

Electronics: Casings, connectors, and assembly parts.

-

Consumer Goods: Toys, household items, and packaging.

The Future of Injection Moulding Automation

The integration of AI, IoT, and smart sensors is shaping the next generation of injection moulding robots. Real-time monitoring, predictive maintenance, and adaptive process control are making production lines more intelligent, efficient, and profitable.

Conclusion

Injection moulding robots are redefining manufacturing standards. They enhance productivity, maintain consistent quality, improve safety, and offer a strong ROI. For companies aiming to stay competitive in modern manufacturing, investing in robotic automation is no longer optional—it’s a necessity.