The hum of activity in a modern distribution center or manufacturing plant has a new soundtrack: the quiet, purposeful whir of Automated Guided Vehicles (AGVs). These self-navigating robots, once limited to following fixed wires or tracks in predictable environments, have undergone a radical evolution. Today, they are intelligent, mobile robots capable of complex decision-making, seamlessly collaborating with human workers, and adapting to dynamic environments in real-time. This transformation is not just about automating material movement; it's about creating a fully integrated, responsive, and agile operational ecosystem that can meet the demands of e-commerce, just-in-time manufacturing, and global logistics.

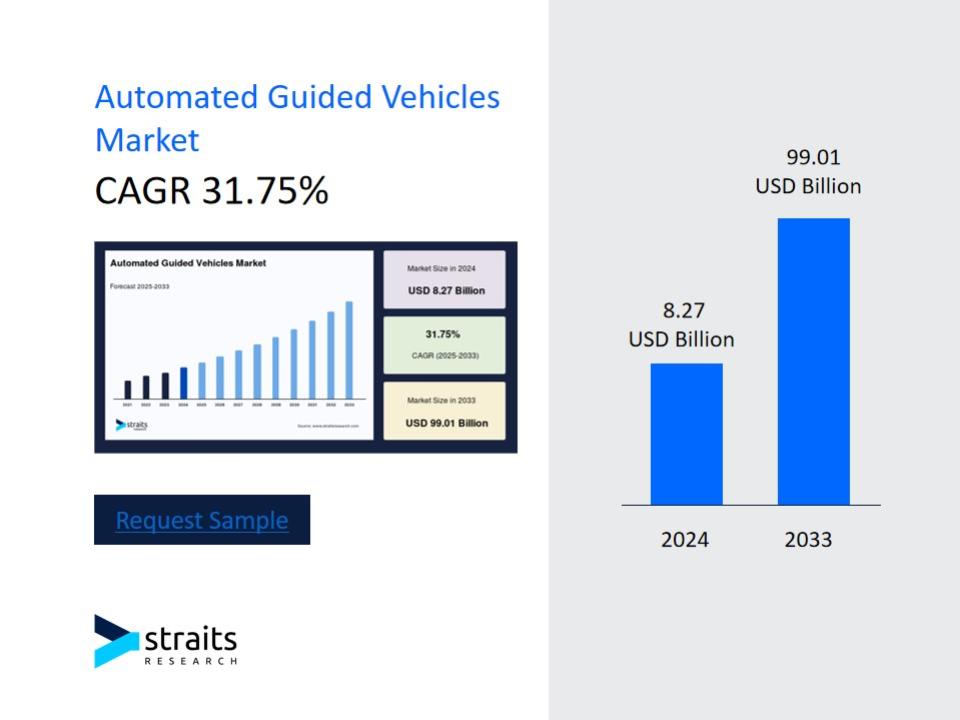

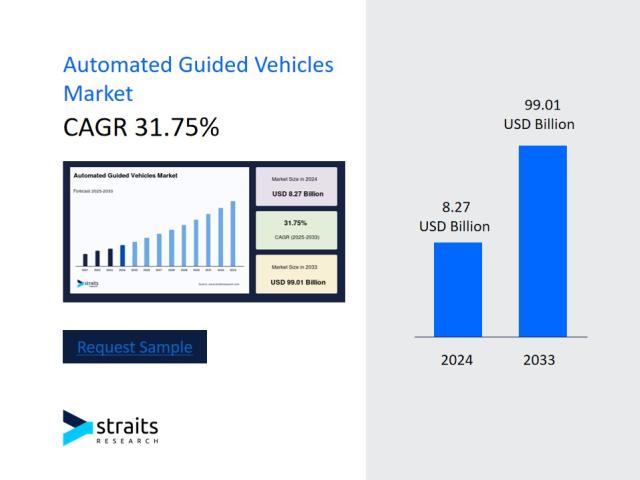

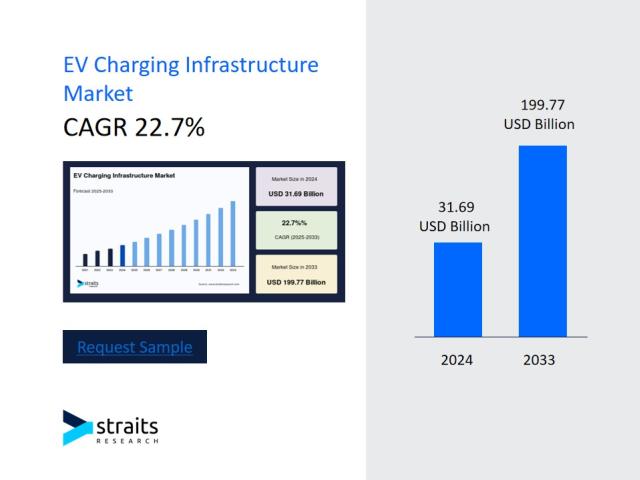

The pace of this adoption is accelerating at a staggering rate. According to Straits Research, the global automated guided vehicles was valued at USD 8.27 billion in 2024 and is expected to grow from USD 10.90 billion in 2025 to reach USD 99.01 billion by 2033, growing at a CAGR of 31.75% during the forecast period (2025-2033). This exponential growth is fueled by the relentless pressure of e-commerce, persistent labor shortages, and the critical need for operational resilience and efficiency in the face of global supply chain challenges.

Key Players and Strategic Advancements: A Global Race for Autonomy

The landscape is a dynamic mix of established industrial automation giants and agile robotics startups, each pushing the boundaries of what's possible.

-

KION Group (Dematic) (Germany): A global leader in industrial trucks and supply chain solutions, KION, through its Dematic brand, offers a comprehensive range of AGVs and Autonomous Mobile Robots (AMRs). Their recent strategy focuses on integrated system solutions. A key 2024 update is the enhanced intelligence of their Dematic AGV portfolio, which now features improved fleet management software that allows for seamless coordination between hundreds of vehicles, optimizing traffic flow and charge cycles without human intervention.

-

Toyota Advanced Logistics (Japan): Building on the Toyota Production System's legacy of efficiency, Toyota has become a powerhouse in material handling automation. Their recent innovations include the development of "vision-guided" AGVs that can perform complex tasks like automatically loading and unloading standard shipping containers, a significant advancement in port and cross-dock operations. They are heavily focused on the Asian and North American markets.

-

Omron Automation (United States/Japan): Omron has made significant strides with its LD series mobile robots. Their recent news highlights advancements in human-robot collaboration. Their latest models use advanced safety sensors and AI to dynamically adjust their paths in real-time when a human worker enters their operational zone, enabling true mixed-work-cell environments without the need for safety caging.

-

KUKA AG (Germany): Known for its robotic arms, KUKA is a major player in industrial automation. Their KMR series of mobile robots is designed to act as agile mobile platforms that can be equipped with robotic arms (mobile manipulators), creating a robot that can navigate to a location and then perform a precise task like picking or assembly. This flexibility is a key differentiator in complex manufacturing settings.

-

Geek+ (China): A rising star and one of the world's most well-funded AMR startups, Geek+ represents the new wave of agile robotics firms. They have seen explosive growth, particularly in e-commerce fulfillment. Their recent updates include the launch of a new robotic sorter and a partnership with a major European logistics firm to deploy a fleet of over 1,000 robots for parcel sorting, showcasing the massive scale at which these systems can now operate.

Emerging Trends: The Shift to Intelligence and Flexibility

The evolution of AGVs is defined by several key trends. The most significant is the industry-wide shift from traditional AGVs to Autonomous Mobile Robots (AMRs). While AGVs often follow fixed pre-defined paths (wires, magnetic tape), AMRs use sophisticated sensors, cameras, and LiDAR to map their environment and navigate dynamically. This allows for easier deployment, reconfiguration, and the ability to handle unpredictable environments.

Secondly, the rise of AI and Machine Learning is making these robots smarter. Fleet management software now uses AI to perform predictive analytics, forecasting bottlenecks and pre-emptively repositioning robots to where they will be needed most. Furthermore, interoperability is becoming a major focus, with companies and industry groups developing standards to allow robots from different manufacturers to communicate and collaborate on the same warehouse floor.

Recent News and Regional Updates

The sector is buzzing with activity and investment. In recent months, Amazon announced a major expansion of its robotic fleet, including new, larger AGVs for pallet movement, further cementing its position as one of the world's largest operators of industrial robots. In Europe, a recent partnership between Volvo Group and a leading AGV manufacturer was unveiled to automate material handling in their truck assembly plants, highlighting the adoption beyond traditional warehousing.

In the Asia-Pacific region, governments in countries like South Korea and Singapore are offering subsidies to small and medium-sized enterprises to adopt automation, triggering a wave of demand for collaborative and smaller-scale AGV solutions. This policy-driven growth is creating significant opportunities for local and international players alike.

The challenges remain, including high initial integration costs and the need for specialized technical expertise. However, the return on investment through increased throughput, reduced labor costs, improved safety, and 24/7 operational capability is proving irresistible for a growing number of industries, from automotive and aerospace to pharmaceuticals and retail.

In summary, the era of rigid, dumb automatons is over. The new generation of Automated Guided Vehicles are intelligent, flexible, and collaborative partners in the supply chain. They are the central nervous system of the modern automated facility, driving a revolution in how goods are moved, stored, and delivered across the globe.