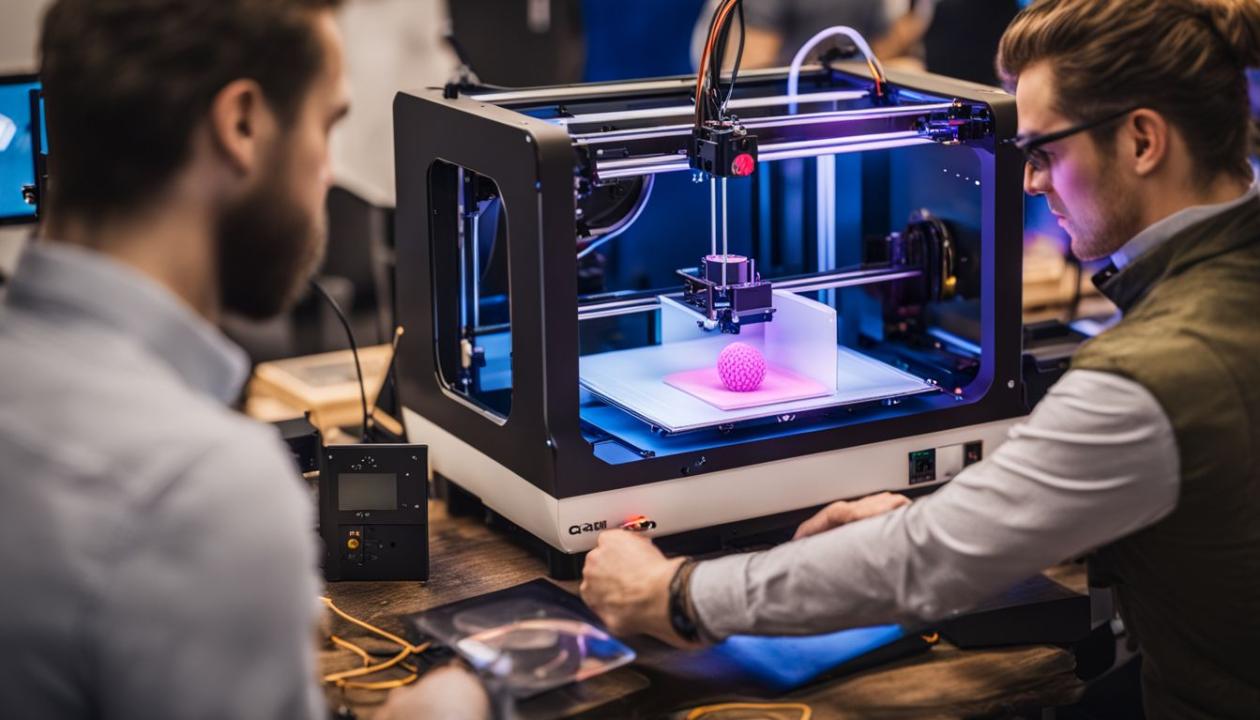

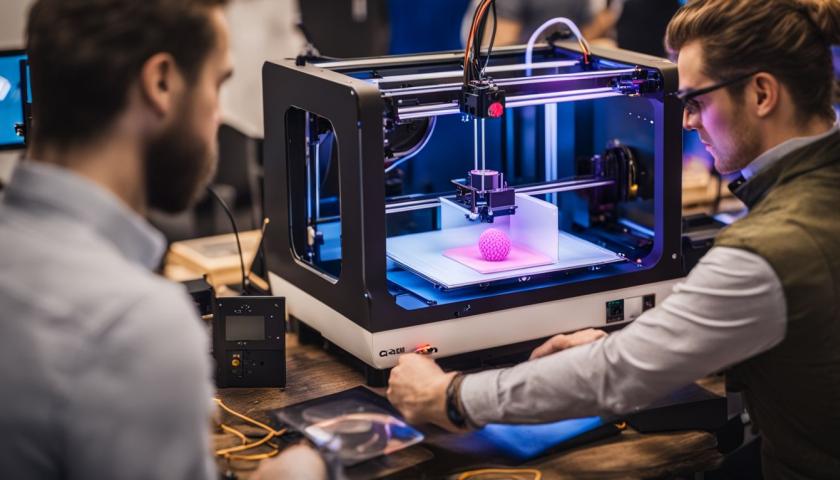

The rapidly evolving world of 3D printing is increasingly reliant on advanced software and comprehensive services that drive design, fabrication, and post-production processes. In 2025, 3D printing software and services are fueling innovation across industries such as aerospace, automotive, healthcare, and consumer goods, enabling highly customized, complex, and efficient additive manufacturing workflows. This sector is marked by the integration of AI, cloud computing, and automation, transforming how prototypes and production-grade parts are designed and made globally.

According to Straits Research, "The global 3D printing software and services market size was valued at USD 28.35 billion in 2024 and it is projected to reach from USD 35.07 billion in 2025 to USD 192.29 billion by 2033, registering a CAGR of 23.7% during the forecast period (2025-2033)." This explosive growth reflects surging adoption of software solutions that simplify complex printing processes and expanding services supporting end-to-end additive manufacturing ecosystems.

Cutting-Edge Innovations and Recent Updates

Recent developments highlight the growing sophistication and scope of 3D printing software and services:

-

Cloud-based platforms like 3DPrinterOS revolutionize workflow management, allowing remote control, real-time print monitoring, and collaboration across multiple devices and teams.

-

AI-powered generative design tools enable automated optimization of print models, minimizing material use while maximizing functional performance, especially useful in aerospace and automotive industry applications.

-

Software suites such as Materialise Mimics Innovation and Magics continue to evolve, accelerating medical 3D printing with advanced imaging import, data processing, and quality control, thus shortening production cycles for custom implants and devices.

-

Automation and integration with manufacturing execution systems (MES) streamline batch production, part tracking, and quality assurance, positioning 3D printing as a viable mass production technology beyond prototyping.

-

Multi-material printing and color management software solutions enhance aesthetic and functional diversification in consumer products and medical applications.

-

End-to-end service providers offer consulting, design support, training, and supply chain management, addressing the complexity and learning curve faced by new adopters.

Major Players and Regional Insights

Market leaders and innovators dominate with extensive portfolio offerings across software and services:

-

Stratasys Ltd. (US/Israel): Maintains leadership through integrated hardware-software ecosystems and manufacturing services, focusing on industrial, aerospace, and health sectors.

-

3D Systems, Inc. (US): Offers a broad range of software solutions supporting diverse printing technologies, emphasizing medical and aerospace applications with AI enhancements.

-

Autodesk Inc. (US): Known for AutoCAD and Fusion 360, Autodesk continues to push cloud-based CAD and generative design tools optimized for additive manufacturing workflows.

-

Materialise NV (Belgium): Innovates with application-specific software, driving medical and industrial adoption through extensive service offerings and collaborations.

-

Siemens Digital Industries Software (Germany) and Dassault Systèmes (France): Provide simulation and lifecycle management platforms integrating additive manufacturing to optimize design-to-production cycles.

-

Asia-Pacific leads rapid adoption, driven by government incentives, electronics manufacturing growth, and emerging local software startups enhancing regional competitiveness.

-

North America and Europe sustain high investments in R&D and infrastructure supporting end-to-end 3D printing services and advanced software solutions for complex industrial applications.

-

India and Latin America emerge as fast-growing regions leveraging 3D printing for healthcare, aerospace, and automotive sectors, increasing demand for localized service providers.

Trends Shaping the Future

-

AI and machine learning integration into design software enables “smart” print preparation, defect prediction, and process optimization, radically improving productivity and yield quality.

-

Increasing cloud adoption facilitates global collaboration, remote printing, and centralized fleet management for enterprises managing dispersed production.

-

Industrialization of additive manufacturing moves beyond prototyping to full-scale production lines, supported by software suites that automate production scheduling, quality control, and traceability.

-

Integration of CAD, simulation, and printing preparation reduces lead times in aerospace, automotive, and medical device manufacturing, enhancing competitive advantage.

-

Sustainability drives software features to optimize material usage, recycling, and energy efficiency in print processes while enabling design for sustainability principles.

-

Service-oriented business models evolve, bundling hardware, software, consulting, and maintenance into seamless customer experiences and helping reduce adoption barriers.

Recent News Highlights

-

Materialise released a new update to Mimics Innovation Suite in early 2025, significantly boosting AI-driven image processing speed and model accuracy for medical 3D printing.

-

Autodesk expanded Fusion 360’s generative design capabilities with enhanced cloud simulation and multi-material support, accelerating industrial adoption by global customers.

-

3DPrinterOS announced partnerships with leading hardware manufacturers to offer integrated cloud management for entire printing fleets, facilitating remote monitoring and predictive maintenance.

-

Stratasys launched a new additive manufacturing service hub in Europe, combining software-driven quality assurance with on-demand production for industrial clients.

-

Siemens introduced new lifecycle management modules incorporating 3D printing preparation and simulation, helping manufacturers improve design iteration cycles.

-

Emerging APAC-based firms like Materialise India provide localized end-to-end 3D printing services, targeting healthcare and automotive OEMs with tailored software and consultation.

Conclusion

The fusion of advanced software and comprehensive service platforms is revolutionizing the 3D printing industry, transforming it into a flexible, scalable technology embedded deep into manufacturing and healthcare ecosystems worldwide.