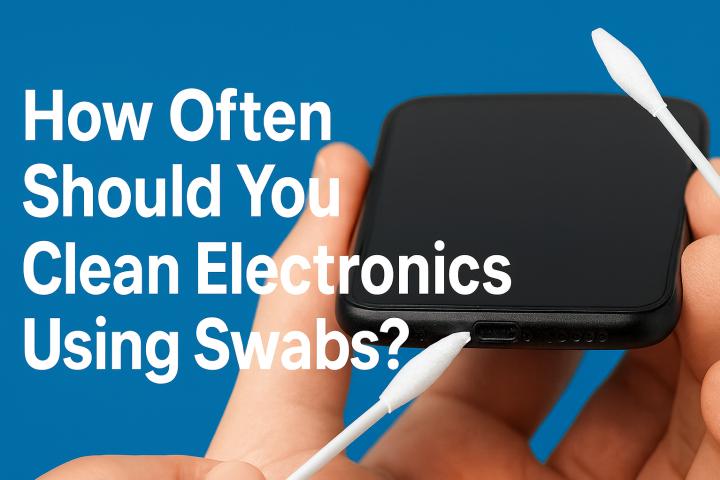

When working with sensitive electronics, dust, grease, and microscopic particles can affect performance and even cause long-term damage. Foam tipped cleaning swabs are one of the most effective tools for maintaining delicate electronic components. These precision swabs are designed to reach tight spaces, remove contaminants, and keep devices functioning at their best without scratching or leaving behind lint.

Why Foam Tipped Swabs Are Ideal for Electronics

Unlike cotton buds that may shed fibers, foam tipped swabs are manufactured from durable open-cell foam. This material provides excellent absorbency and solvent compatibility, making it easy to use them with cleaning solutions like isopropyl alcohol. The soft foam surface ensures thorough cleaning while protecting fragile surfaces such as circuit boards, sensors, and connectors.

Applications in Electronic Maintenance

Foam tipped cleaning swabs are widely used across multiple areas of electronics care:

- PCB and Circuit Boards – removing flux residues or dust between fine soldered joints.

- Keyboards and Switches – reaching narrow gaps that collect dirt and oil.

- Printer Heads and Optical Equipment – ensuring precision parts stay free from buildup.

- Smartphone Ports and Cameras – cleaning small, sensitive openings without risk of damage.

Advantages Over Other Swab Types

While polyester swabs are also popular for cleanroom and laboratory environments, foam tipped swabs stand out for electronics due to their higher absorbency and cushioning effect. They are reusable for light cleaning and designed to reduce contamination risks during maintenance.

When to Use Sterile Options

For environments that demand the highest level of cleanliness, such as medical devices or semiconductor facilities, a Sterile Polyester Swab WDP 759 may be preferred. However, for most consumer and industrial electronics, foam tipped swabs provide the right balance of effectiveness, safety, and cost-efficiency.

Final Thoughts

Foam tipped cleaning swabs are an essential tool for anyone handling sensitive electronics, from hobbyists repairing gadgets to professionals maintaining advanced systems. Their combination of precision, safety, and compatibility with cleaning solvents makes them the go-to choice for protecting valuable electronic components.