When you're setting up servers, network equipment, or other critical devices, power connections matter more than you might think. Two common connectors you'll encounter are C13 and C15. They look almost identical, but there's one crucial difference that could protect your equipment from overheating damage.

Understanding the Basics

Both C13 and C15 are IEC (International Electrotechnical Commission) standard power connectors. You'll find them on the back of computers, servers, monitors, and networking gear. An IEC C13 power cord is one of the most common types you'll see in data centers and offices around the world.

At first glance, these connectors seem interchangeable. They're both rated for the same voltage and amperage. So what makes them different? The answer lies in their temperature ratings.

The Key Difference: Temperature Ratings

The C13 connector is rated for temperatures up to 70°C (158°F). This works fine for most standard office equipment that doesn't generate excessive heat.

The C15 connector, however, is rated for temperatures up to 120°C (248°F). That's a significant jump of 50 degrees Celsius. This higher rating makes C15 connectors essential for devices that run hot or operate in warm environments.

Why Temperature Ratings Matter

Heat is one of the biggest enemies of electronic equipment. When devices overheat, several problems can occur:

- Components degrade faster

- Performance drops

- Safety risks increase

- Equipment lifespan shortens

- Fire hazards become possible

Using the wrong connector type means you're not accounting for the heat your device generates. This oversight can lead to melted connectors, damaged equipment, or even dangerous situations.

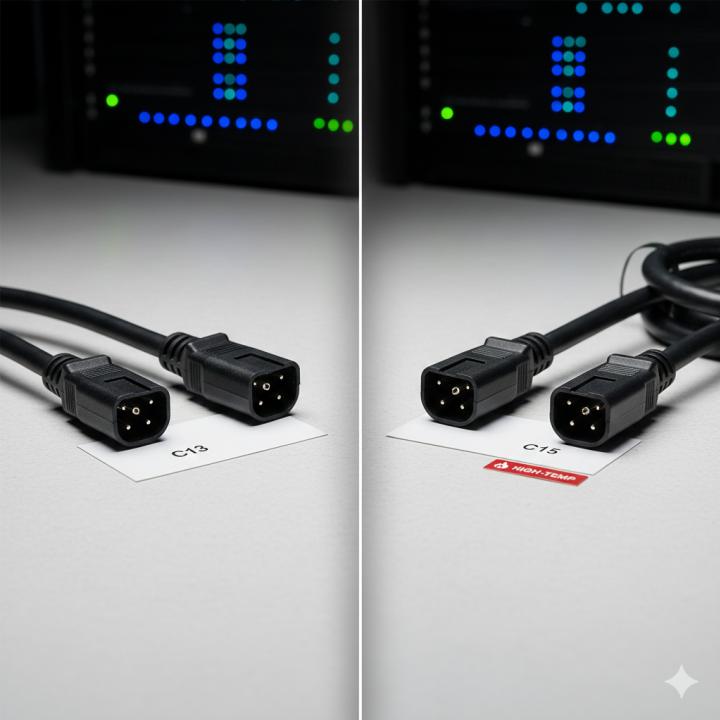

Identifying C13 vs C15 Connectors

Here's how to tell them apart:

The C13 connector has three rectangular slots arranged in a specific pattern. The design is straightforward and simple.

The C15 connector looks similar but has a notch cut into the top. This notch serves two purposes. First, it allows hot air to escape more effectively. Second, it prevents you from accidentally plugging a C13 cord into a C15 inlet.

This design is intentional. You can plug a C15 cord into a C13 inlet, but not the other way around. This prevents you from using a lower-rated connection on a high-temperature device.

When to Use Each Type

Use C13 connectors for:

- Desktop computers

- Monitors

- Printers

- Standard office equipment

- Network switches (low-power models)

- Most consumer electronics

These devices typically don't generate enough heat to exceed the 70°C rating. An IEC C13 power cord handles these applications perfectly.

Use C15 connectors for:

- High-powered servers

- Hot-swappable power supplies

- Electric kettles and water boilers

- High-performance computing equipment

- Devices in hot environments

- Equipment that runs continuously under load

These applications produce significant heat. The higher temperature rating of C15 provides the safety margin you need.

Real-World Scenarios

Let's look at some practical examples.

Imagine you're setting up a server room. Your servers have dual power supplies for redundancy. These power supplies work hard and generate considerable heat. Using a standard IEC C13 power cord here would be risky. The connector might soften over time, causing poor electrical contact. This leads to more heat, creating a dangerous cycle.

With C15 connectors, your setup handles the heat safely. The components maintain their integrity even when temperatures rise during peak loads.

Another scenario: You're replacing power cords in an older data center. The room temperature runs warmer than ideal. Even if individual devices seem fine with C13, the ambient heat adds to the connector temperature. Upgrading to C15 connectors adds an extra safety buffer.

Common Mistakes to Avoid

Many people make these errors when choosing power connectors:

Assuming all power cords are the same. They're not. Temperature ratings exist for good reasons. Don't ignore them.

Using C13 because it's cheaper. The small cost difference isn't worth the risk to expensive equipment or safety.

Not checking device specifications. Always verify what the manufacturer recommends. If your device has a C15 inlet, use a C15 cord.

Ignoring environmental factors. Hot rooms, poor ventilation, and direct sunlight all add to connector temperatures.

Making Decisions Based on Your Needs

How do you know which connector your setup requires? Ask yourself these questions:

Does your equipment generate significant heat? Check the device specifications for operating temperatures.

What's the ambient temperature? Consider your room conditions, not just the device itself.

How long does the equipment run continuously? Devices that never shut down accumulate more heat.

What does the manufacturer specify? Always follow their recommendations first.

Is there adequate ventilation? Poor airflow increases temperature risks.

The Cost of Getting It Wrong

Using an IEC C13 power cord on a device that needs C15 might save a few dollars initially. But the potential costs far outweigh those savings:

- Replacing damaged equipment

- Downtime and lost productivity

- Potential data loss

- Safety incidents

- Liability concerns

- Insurance complications

Critical devices earn their name because they're essential to your operations. Don't compromise their reliability over a minor component choice.

Best Practices for Power Connection Safety

Follow these guidelines to ensure safe, reliable power connections:

Always match the connector type to the device inlet. Don't force incompatible connectors.

Inspect connections regularly. Look for discoloration, melting, or unusual warmth.

Ensure proper ventilation around power connections. Don't block airflow with cables or equipment.

Replace damaged cords immediately. Never use cords with worn or compromised connectors.

Keep spare cords on hand. Having the right type available prevents emergency shortcuts.

Document your setup. Note which devices use which connector types for future reference.

Conclusion

The difference between C13 and C15 connectors comes down to temperature tolerance. That 50-degree difference might not seem like much on paper, but it's critical for equipment safety and longevity.

An IEC C13 power cord serves most standard applications well. But when devices run hot or operate in challenging environments, C15 connectors provide essential protection against overheating.

Taking the time to choose the right connector type protects your investment in critical equipment. It prevents safety issues and ensures reliable operation when you need it most. The next time you're connecting power to important devices, check that temperature rating. Your equipment will thank you with years of trouble-free service.

Sources: https://indiangeek.in/iec-c13-vs-c15-power-cords-whats-the-difference-and-when-to-use-each/

https://zekond.com/read-blog/295555