In a world that is rapidly moving

toward sustainability, businesses are looking for packaging and promotional

solutions that balance functionality, branding, and environmental

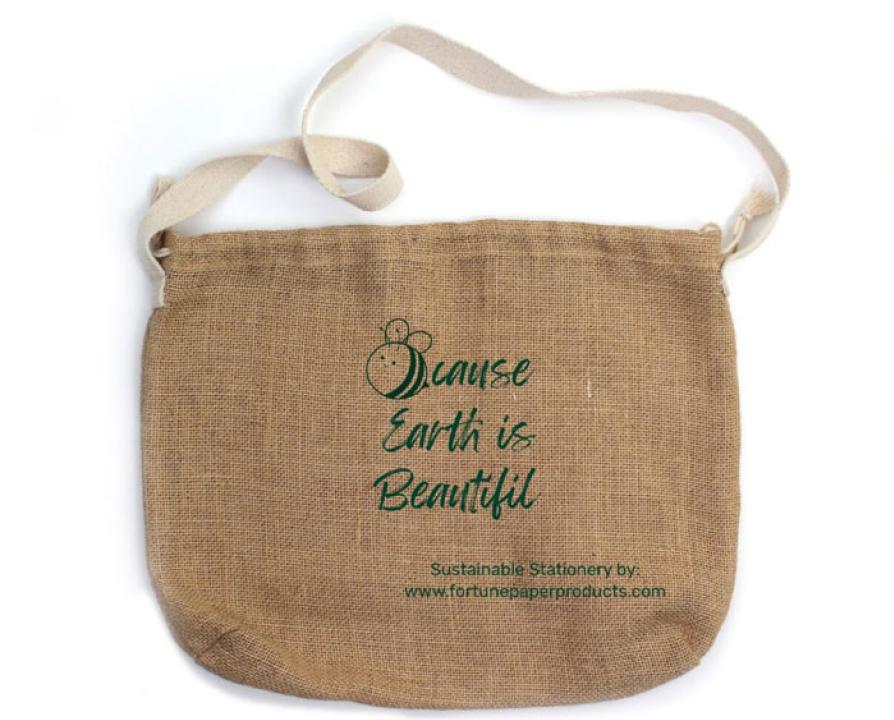

responsibility. Custom jute bags have emerged as one of the most powerful eco-friendly

branding tools available today. They are reusable, biodegradable, and

impressively versatile — but the real magic happens behind the scenes, where

skilled jute bag manufacturers transform simple ideas into finished

eco-products that tell a brand’s story.

From selecting the raw fiber to

weaving fabric, printing, and final finishing, each stage of jute bag

production involves craftsmanship, technology, and sustainable thinking.

Whether you’re a startup exploring green packaging or an established brand launching

a custom merchandise line, understanding how manufacturers convert concepts

into real, functional products will help you make informed decisions.

This guide walks you through the

full journey: how custom jute bags come to life, what steps manufacturers

follow, and how you can collaborate effectively with the right production

partner.

Why

Jute Is the Ideal Eco Material

Before diving into the creation

process, it’s worth understanding why jute is prized for custom products.

- Renewable & biodegradable: Jute fiber grows quickly with minimal fertilizers, and

the final bag decomposes naturally.

- Durable:

Its tensile strength makes it ideal for shopping bags, fashion totes, and

heavy-duty packaging.

- Cost-effective:

Despite being a natural fiber, jute is affordable for mass production.

- Brandable: Jute fabric takes printing well and can be >

These advantages make jute bags a

win-win for both sustainability and branding.

How Manufacturers Turn Ideas Into Custom Jute Bags

1.

Understanding the Client’s Vision

Every custom jute bag begins with a

conversation.

Professional jute bag

manufacturers start the process by capturing:

- The purpose of the bag (shopping, gifting, retail

packaging, events, merchandise, etc.)

- Target audience and usage

- Required size, shape, and >

- Weight-carrying requirements

- Branding and color preferences

- Budget and delivery timelines

Many clients initially have only a

rough concept — manufacturers help translate these ideas into workable

specifications. This early consultation ensures that the final product meets

both creative and functional expectations.

2.

Material Selection: Choosing the Right Jute Fabric

Jute fabric isn’t one-size-fits-all.

Manufacturers select materials based on:

Fabric

Weight

Ranging from 8 oz to 20 oz, the

weight determines durability.

- Lightweight jute:

Best for promotional giveaways or simple packaging.

- Heavy jute:

Ideal for shopping bags, groceries, or rugged product packaging.

Types

of Fabric

- Hessian (or burlap):

Lightweight and flexible.

- Sacking:

Thicker, rougher, used for heavy-duty bags.

- Jute-cotton blends:

Softer, better for stylish or premium bags.

- Laminated jute:

Provides structure and water resistance.

The right fabric ensures the product

performs well in real-life use.

3.

Designing the Bag Structure

Experienced jute bag manufacturers

help convert the client’s creative ideas into practical designs.

Key

structural elements include:

- Bag dimensions:

Width, height, gusset size.

- Handle >

Jute rope, cotton padded handles, bamboo, riveted handles, or custom materials.

- Reinforcements:

Bottom boards, edge piping, or double-stitched seams.

- Closures:

Zippers, buttons, Velcro, drawstrings, magnetic snaps.

- Accessories:

Inner pockets, tags, and custom labels.

Digital mockups and physical

prototypes allow clients to visualize the final outcome.

4.

Custom Printing & Branding

Branding is the heart of custom jute

bags.

Manufacturers offer multiple

printing techniques:

Screen

Printing

Most common for bold, single or

dual-color designs.

Durable and cost-effective.

Digital

Printing

Used for detailed graphics or

multi-color artwork.

Ideal for high-end branding.

Heat

Transfer

Allows photo-like imagery but works

best on laminated jute.

Embroidery

Premium finish for high-value,

fashion-oriented bags.

Sustainable manufacturers use:

- Water-based inks

- AZO-free dyes

- Eco-friendly printing processes

This ensures the branding aligns

with your sustainability claims.

5.

The Cutting & Stitching Process

After designing and printing, the

production phase begins.

Cutting

Fabric is precisely cut according to

the approved measurements to avoid waste.

Stitching

Skilled workers assemble the bag

using industrial sewing machines. Key stitching methods include:

- Lockstitch

- Chain stitch

- Cross-stitch reinforcement for handles

This stage defines the strength,

durability, and appearance of the final bag. Manufacturers with strict quality

control check:

- Seam alignment

- Thread tension

- Handle strength

- Print accuracy

The goal is to create a bag that is

not only beautiful but also long-lasting.

6.

Lamination and Finishing Touches

Depending on the bag’s purpose,

manufacturers may add:

Lamination

- Clear lamination:

For water resistance.

- Matt/Gloss finish:

For premium branding.

- Biodegradable coatings: More eco-friendly alternative.

Edge

binding

Fabric tape is stitched onto the

edges for a clean finish.

Bottom

inserts

A reinforced base keeps the bag structured.

Ironing

and shaping

Bags are steamed or pressed to

maintain shape.

Professional jute bag manufacturers

treat the finishing stage as a key part of the product’s aesthetic value.

7.

Quality Testing and Inspection

Reputable manufacturers follow

strict QC protocols:

- Load testing

to check weight capacity

- Rubbing tests

to ensure prints don’t fade

- Needle detection

for safety in export markets

- Visual inspection

for defects

Inspection ensures consistency

across mass orders — crucial for businesses that rely on brand reputation.

8.

Eco-Friendly Packaging and Shipping

The commitment to sustainability

extends to packaging.

Manufacturers typically use:

- Recyclable or compostable outer packaging

- Minimal plastic use

- Efficient carton packing that reduces shipping volume

Eco-conscious jute bag

manufacturers also recommend shipping options with lower carbon impact or

consolidated deliveries for large orders.

Working With the Right Manufacturer: What to Expect

Choosing the right manufacturing

partner determines your entire experience. A professional manufacturer should

offer:

- Transparent quotes

- Detailed product mockups

- Low or flexible MOQ options

- Timely sample development

- Clear communication

- Export expertise

- High-quality raw materials

- Proven sustainability practices

Good communication ensures your

ideas translate into the exact eco-friendly product you envision.

Why Custom Jute Bags Are a Smart Investment

1.

Sustainable Branding

Consumers love brands that care

about the environment. Jute bags are a visible, reusable symbol of commitment.

2.

Versatility Across Industries

Custom jute bags are used in:

- Retail

- Cosmetics

- Corporate gifting

- Food and grocery stores

- Life>

- Events and promotions

3.

High Return on Investment

Reusable bags offer long-term brand

exposure — your logo stays visible for months or even years.

4.

Reduced Environmental Impact

Choosing sustainable packaging

improves corporate image, supports global eco goals, and reduces single-use

plastic waste.

Final Thoughts

Behind every custom jute bag lies a

creative and meticulous process — from raw fiber selection to printing,

stitching, finishing, and testing. Skilled jute bag manufacturers

transform ideas, sketches, and brand messages into tangible eco-products that

customers use repeatedly.

As sustainability becomes a global

priority, investing in custom jute bags isn’t just a trend — it’s a strategic

decision that shows your brand cares about the future. With the right manufacturing

partner, your business can turn eco-conscious ideas into powerful, functional,

and beautiful products that stand out.