Checking the quality of electric cables is crucial for safety and efficiency. Using low-quality cables can cause overheating, short circuits, and damage to devices. Whether you are setting up home appliances, industrial equipment, or data centers, ensuring the cable quality protects both equipment and people. NEMA cables are widely used for their reliability, but verifying quality before use is still essential.

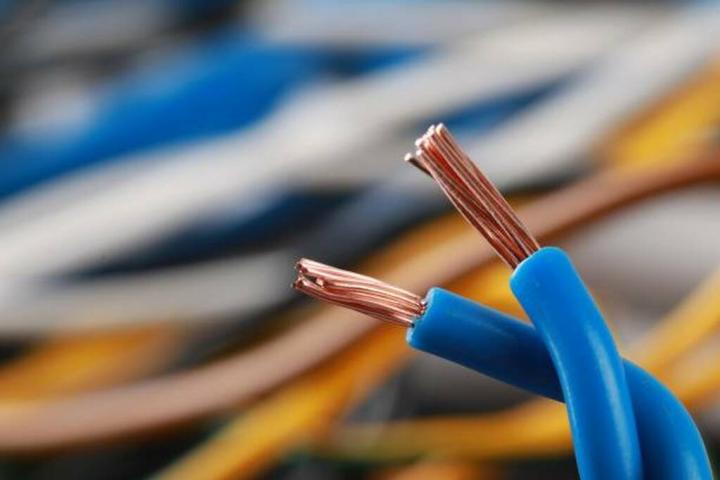

The first step is to inspect the cable visually. Look for any visible damage, cuts, or cracks on the insulation. Damaged insulation can expose wires, creating a risk of electric shock or fire. A high-quality cable should have a smooth, intact outer layer without any signs of wear or fraying.

Next, check the cable markings. Quality cables have clear labeling that indicates voltage rating, current rating, manufacturer details, and certification marks. NEMA cables, for example, often include a certification code to ensure they meet safety and performance standards. Avoid cables with missing or unclear markings.

Feel the cable for flexibility. A good cable should bend without cracking or feeling too stiff. Flexible cables are easier to install and less likely to break internally. Rigid or brittle cables can be a sign of poor material quality, which may lead to performance issues over time.

Examine the connectors carefully. Connectors should fit snugly and be made of durable material. Loose or cheap connectors can cause poor contact, overheating, and electrical faults. NEMA cables usually come with standardized connectors that ensure secure and safe connections with compatible outlets.

Check the wire gauge. The thickness of the wire affects its capacity to carry current. Thicker wires carry more current safely. Using a cable with an insufficient gauge can cause overheating and reduce the lifespan of your devices. NEMA cables are available in various gauges, so choose one that matches your equipment’s requirements.

Test the cable with a multimeter if possible. Measuring resistance and continuity helps confirm that the internal wiring is intact. A cable with high resistance may have poor conductivity, which can affect performance. Proper testing ensures that the cable functions correctly before installation.

Look for shielding and insulation quality. Shielded cables prevent electromagnetic interference, which is important for data transmission. Good insulation protects against electric shock and environmental factors such as heat, moisture, and abrasion. High-quality NEMA cables have reliable insulation that lasts longer and performs safely under stress.

Check for compliance with safety standards. Certified cables meet strict testing requirements to ensure safety and durability. NEMA cables often carry certification marks indicating compliance with industry standards. Using certified cables reduces the risk of accidents and improves long-term reliability.

Consider the length of the cable. Longer cables may experience voltage drops if not properly rated. Measure the required distance and choose a cable that is slightly longer than needed to prevent tension or stretching. Proper length prevents strain on connectors and reduces the risk of damage.

Assess the cable for heat resistance. Cables used in high-power applications or hot environments must withstand high temperatures. Poor-quality cables may melt or lose conductivity when exposed to heat. NEMA cables are designed to handle different temperature ranges, making them suitable for both indoor and industrial use.

Smell the cable. While it may sound unusual, high-quality cables do not have a strong chemical odor. Strong plastic or rubber smells can indicate low-quality materials that may degrade faster or emit harmful fumes over time.

Check the weight of the cable. Generally, heavier cables indicate thicker conductors and better insulation. Lightweight cables may use thin wires or cheap materials, which can compromise safety and performance. NEMA cables usually feel solid and well-constructed.

Examine the cable for certification labels or quality seals. Recognized certification logos confirm that the cable has passed rigorous testing. Avoid buying cables without certifications, as they may not meet safety standards. Quality NEMA cables always come with proper certification.

Test the cable under load if possible. Plug in your equipment and check if the cable heats up excessively or loses performance. A good-quality cable maintains stable performance under normal load conditions. Avoid cables that overheat or feel warm to touch during use.

Check the supplier or manufacturer reputation. Buying from reputable brands reduces the risk of poor-quality cables. Reliable manufacturers follow strict quality controls and provide warranties. NEMA cables from trusted brands ensure durability and safe operation.

Evaluate the outer jacket material. The jacket should be resistant to abrasion, moisture, and UV exposure if used outdoors. Durable jackets protect the internal wires and prolong the cable’s life. Low-quality jackets crack easily and expose wires to hazards.

Verify the cable’s bending radius. Cables should be flexible enough to bend around corners without damaging internal wires. Exceeding the recommended bending radius can cause breaks or short circuits. NEMA cables are designed with proper flexibility for safe installation.

Inspect the cable ends for proper sealing. Poorly sealed ends can allow dust or moisture to enter, leading to corrosion or failure. NEMA cables typically have well-sealed ends to maintain safety and performance. Proper sealing also prevents accidental short circuits.

Consider future needs. Choose cables that can handle potential upgrades or higher loads. Selecting slightly higher-rated NEMA cables ensures long-term usability without replacement. Planning ahead avoids unnecessary costs and disruptions in the future.

Finally, trust your instincts. If a cable feels cheap, smells strong, or seems poorly made, it is better to choose another option. Investing in high-quality cables like certified NEMA cables ensures safety, durability, and reliable performance. Checking quality before installation protects both your devices and your environment from potential hazards.

In conclusion, checking electric cable quality involves careful inspection of visual appearance, markings, flexibility, connectors, gauge, insulation, certification, and performance under load. NEMA cables are a trusted choice because of their reliable construction and standardized ratings. By following these steps, you can ensure your cables are safe, efficient, and long-lasting, providing peace of mind and protecting your electrical equipment. Always prioritize quality and certification to avoid risks and maintain smooth operation.

Sources: https://www.pinoybisnes.com/home-living/top-5-things-to-look-for-when-buying-a-nema-power-cable/

https://sfcable.hashnode.dev/what-are-three-things-to-consider-when-choosing-an-ethernet-cord