Industrial Robots in India: Driving the Next Industrial Revolution

In the past decade, industrial robots in india have transformed manufacturing and logistics around the world — and India is no exception. From precision welding on automotive lines to automated packaging and material handling, industrial robots are steadily reshaping how factories operate across sectors.

🚀 India’s Industrial Robotics Landscape: Growth & Scale

India has emerged as one of the fastest-growing markets for industrial robot installations worldwide. In 2023, 8,510 industrial robots were installed in the country, representing a 59% increase year-on-year — the fastest growth rate among major global markets and placing India among the top 10 countries for robot deployments.

Despite this growth, India’s robot density — the number of robots per 10,000 manufacturing workers — remains relatively low compared to global benchmarks, indicating significant room for expansion across industries.

🏭 Key Sectors Boosting Robot Adoption

Industrial robots are increasingly used in:

1. Automotive & Electric Vehicles (EVs)

The automotive industry dominates India’s industrial robot usage, accounting for over 40% of total installations — especially for tasks like assembly, welding, painting, and parts handling.

2. Electronics & Semiconductors

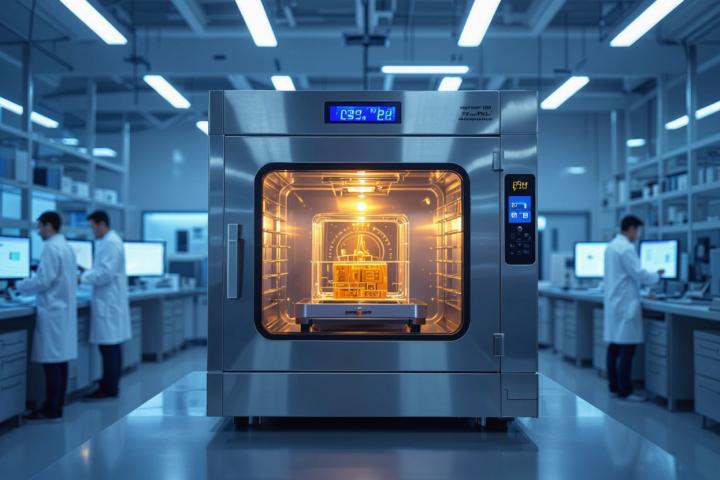

High-precision production demands in the electronics and semiconductor sectors are driving robot use for assembly, inspection, and testing applications.

3. Warehousing & Logistics

With the rise of e-commerce, autonomous mobile robots (AMRs) and sorting robots enhance warehouse throughput, inventory movement, and order fulfillment accuracy.

4. Pharmaceuticals, Food & Consumer Goods

Robots help maintain consistency, hygiene, and speed in packaging, inspection, and processing operations.

🧠 How Industrial Robots Improve Manufacturing

Industrial robots deliver several benefits that make them essential in modern factories:

-

Precision & Speed: Robots consistently perform repetitive tasks with high accuracy and speed, improving product quality and output.

-

Safety: Robotics reduce worker exposure to hazardous or physically demanding tasks, enhancing workplace safety.

-

Efficiency: By automating bottleneck processes, companies can cut cycle times and reduce waste.

-

Cost Savings: Long-term operational savings often offset the initial investment, especially in high-volume production.

🤝 Collaborative Robots (Cobots): The Next Frontier

Alongside traditional industrial robots, collaborative robots, or cobots, are gaining momentum in India — particularly among small and medium enterprises (SMEs). Cobots are designed to work safely alongside humans, are easier to program, and require minimal safety infrastructure compared to traditional robots.

This makes cobots attractive for flexible automation, especially in environments with mixed production tasks and limited factory space.

📊 Challenges & Opportunities

Despite the exciting growth trajectory, India’s industrial robotics adoption faces a few hurdles:

• High Initial Costs

Robots and automation systems require substantial initial investment, which can be a barrier for SMEs without clear short-term ROI.

• Legacy System Integration

Many factories still operate with older equipment, making seamless integration of advanced robotics complex and costly.

Opportunities:

As India continues to modernize manufacturing infrastructure, robotics integration offers a competitive advantage — unlocking productivity gains, global supply chain integration, and new tech-driven job roles in robot operation, maintenance, and programming.

📈 What’s Next for Industrial Robots in India

Industry forecasts suggest the industrial robotics market in India will continue to grow steadily through 2026 and beyond, driven by:

-

Rising automation needs across sectors

-

Government initiatives to boost manufacturing competitiveness

-

Increasing integration of AI, IoT, and data analytics into robotic systems

-

Expanded use of robots in semiconductors, EVs, and logistics

🧩 Conclusion

Industrial robotics in India is no longer a futuristic concept — it’s a strategic reality for manufacturers aiming to scale, innovate, and compete globally. From high-volume automotive production to smart warehouse automation and precision electronics manufacturing, industrial robots are redefining productivity and quality standards across sectors.

As adoption accelerates and technology becomes more accessible, India’s industrial landscape is poised for a new era of smart manufacturing — powered by robots that are more capable, connected, and collaborative than ever before.