In the realm of architectural acoustics, acoustic wood panels have emerged as an elegant and efficient solution to managing sound within interiors. These panels combine natural aesthetics with functional design, allowing spaces to sound better without compromising on >perforation pattern. Understanding these patterns and their impact on sound can transform how we approach acoustic treatments in spaces ranging from concert halls to corporate offices.

Art and Science Behind Acoustic Wood Panels

At first glance, acoustic wood panels might appear to be simply wooden surfaces with decorative holes or slots. But these perforations are far more than mere design elements. They play a pivotal role in controlling sound absorption and diffusion within a room. Essentially, these patterns determine how much sound energy the panel can absorb, reflect, or scatter, influencing overall acoustics.

Wood, as a material, offers excellent acoustic properties. It naturally helps diffuse sound waves, creating a warm, balanced ambiance. When combined with strategically designed perforations, these panels can be optimized to target specific frequency ranges, minimizing echoes, reverberations, and unwanted noise.

Why Perforation Patterns are Good for Acoustics?

Not all perforations are created equal. The size, shape, density, and distribution of holes or slots affect the acoustic performance of wood panels in unique ways. Here’s why these variables are crucial:

Hole Size: Larger holes typically allow more sound to pass through and be absorbed by the material behind the panel. Smaller holes tend to reflect more sound, influencing higher-frequency absorption.

Perforation Density: This refers to the total open area versus the solid wood surface. Higher density means more open area, resulting in increased sound absorption but less surface area for diffusion.

Pattern Shape and Distribution: Circular holes, slots, squares, or decorative shapes affect not only the panel’s acoustic response but also the visual appeal. The pattern can help scatter sound waves, reducing flutter echoes and improving speech intelligibility.

Exploring Different Perforation Patterns

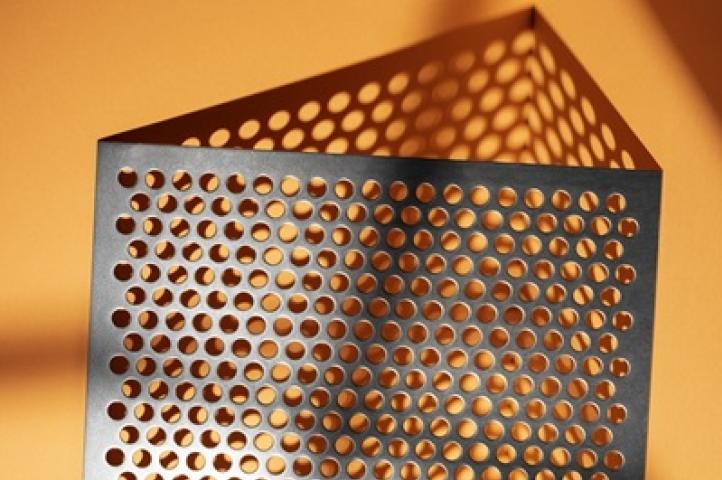

Circular Perforations: The Classic Choice

The most common perforation pattern is the circular hole, favored for its straightforward manufacturing and predictable acoustic properties. Circular perforations create a balance between sound absorption and diffusion, making them versatile for general acoustic treatment in various environments such as offices, auditoriums, and restaurants.

These holes are often arranged in uniform grids or staggered patterns to maximize sound energy absorption while maintaining structural integrity.

Slotted Perforations: Directional Control

Slotted perforations introduce an elongated shape that influences sound differently. These slots can be aligned vertically, horizontally, or diagonally, allowing designers to tailor acoustic effects in specific directions. This directional control is particularly beneficial in spaces where sound needs to be managed along a certain axis, such as lecture halls or conference rooms.

Slots can also enhance the visual dynamics of the panel, lending a modern, sleek aesthetic.

Decorative and Custom Patterns: Marrying Function and Form

In high-end architectural projects, acoustic wood panels are not just functional but also artistic elements. Custom perforation patterns—ranging from organic shapes to intricate motifs—offer unique opportunities to integrate acoustics seamlessly into interior design.

While these artistic patterns prioritize aesthetics, they are still engineered carefully to maintain sound absorption and diffusion properties. Innovative CNC (Computer Numerical Control) cutting technologies enable such precision, ensuring that beauty does not compromise acoustic performance.

Theory of Sound Absorption with Perforated Panels

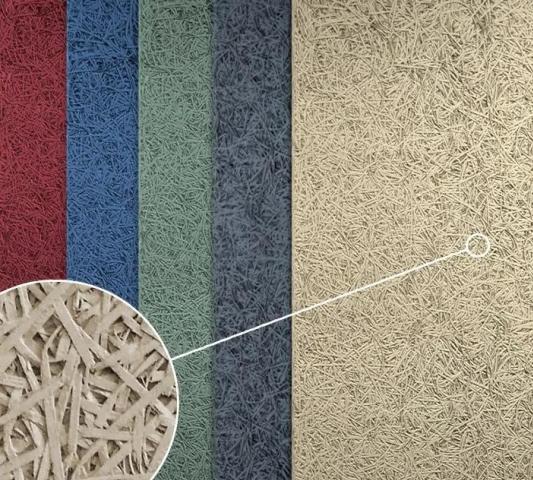

Sound absorption happens when sound waves hit a surface and lose energy, often by converting it into heat within the panel’s core material or the cavity behind it. In acoustic wood panels, the perforations allow sound waves to penetrate the panel, where porous materials such as mineral wool or fiberglass trap and dissipate sound energy.

The key acoustic measurement here is the NRC (Noise Reduction Coefficient), which ranges from 0 (no absorption) to 1 (complete absorption). By varying perforation patterns, manufacturers can design panels with specific NRC ratings suited to different acoustic needs.

For example, a room requiring heavy absorption, like a recording studio, will use panels with larger or denser perforations, combined with thick absorptive backing materials. Conversely, spaces that benefit from more sound reflection and diffusion, such as concert halls, might opt for panels with smaller, more spaced perforations.

How Perforation Patterns Influence Acoustic Wood Panel Applications

Understanding how perforation patterns affect sound allows architects and designers to select the right panel for each space.

In Offices: Open-plan offices often struggle with noise distractions. Panels with medium to high-density circular perforations can absorb mid to high frequencies effectively, reducing chatter and improving speech clarity.

In Theaters and Auditoriums: Larger slots or artistic patterns provide controlled diffusion, ensuring sound spreads evenly without creating dead zones or harsh echoes.

In Restaurants and Cafes: Aesthetic appeal is vital here. Custom perforation designs can enhance ambiance while controlling reverberation to ensure comfortable conversation levels.

In Educational Spaces: Speech intelligibility is crucial. Panels with perforations optimized for mid-frequency absorption help make spoken words clear and reduce background noise.

Beyond Sound

While the acoustic performance is critical, the perforation pattern significantly influences the visual character of wood panels. The pattern acts as a decorative element that can complement architectural themes, from minimalist modern to rustic traditional.

The interplay of light and shadow created by perforations can animate wall surfaces, adding depth and texture. This dual functionality—combining acoustic performance with aesthetic flexibility—makes acoustic wood panels a favored choice among interior designers.

Customization and Innovation: Perforated Acoustic Panels Future

Advances in manufacturing and design software have revolutionized the possibilities of perforation patterns. Using parametric design tools, architects can simulate acoustic behavior and optimize perforation geometry before production, ensuring maximum effectiveness.

Furthermore, combining perforated wood with other materials like acoustic fabrics or diffusive surfaces opens new frontiers in sound control. Hybrid panels that layer different perforation sizes or mix patterns can address complex acoustic challenges in modern multifunctional spaces.

Maintenance and Longevity of Perforated Acoustic Wood Panels

One important consideration when choosing acoustic wood panels with perforations is maintenance. Dust and debris can accumulate in the holes, potentially affecting acoustic performance over time. Selecting panels with easily cleanable finishes or integrating removable covers for the perforations can help preserve function and appearance.

Additionally, high-quality wood and protective coatings extend the panel’s lifespan, ensuring it remains both beautiful and acoustically effective for years.

Conclusion

The relationship between acoustic wood panels and their perforation patterns is a perfect example of where art meets science in interior design. By understanding how these tiny holes shape the way sound behaves, designers can create environments that are not only visually stunning but acoustically comfortable.

Whether the goal is to reduce noise, enhance speech clarity, or simply add a touch of natural elegance, the choice of perforation pattern is key to unlocking the full potential of acoustic wood panels. With growing awareness of acoustic wellbeing in modern architecture, these panels will continue to evolve, offering innovative solutions that delight the eyes and soothe the ears.