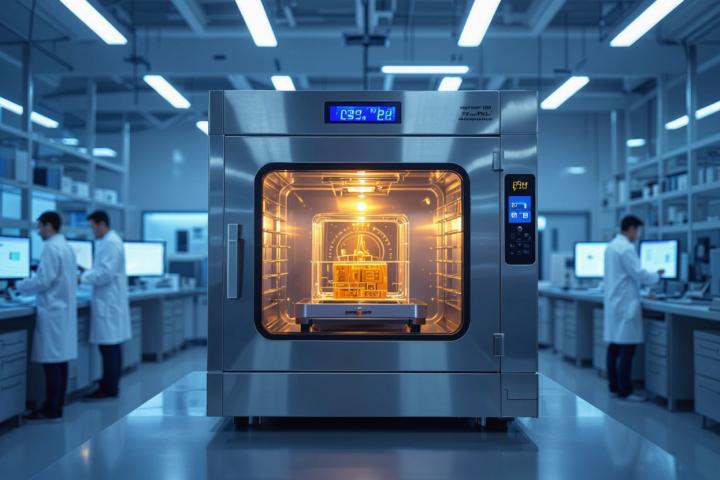

In today's fast-paced industrial world, efficiency, accuracy, and consistency are more important than ever. Manufacturers are under constant pressure to produce high-quality products at lower costs and faster rates. One of the most transformative innovations aiding this cause is the use of robots for moulding. Whether in plastic injection moulding, metal casting, or rubber compression, robots are playing a critical role in reshaping the future of manufacturing.

What Are Moulding Robots?

Moulding robots are industrial robots specifically designed to automate various tasks in the moulding process. These include:

- Loading raw materials into the mould

- Removing finished parts from moulds

- Sprue cutting and deflashing

- Insert loading and over-moulding

- Quality inspection and sorting

They are typically used alongside injection moulding machines, die casting machines, and compression moulding setups, offering flexible automation solutions for repetitive and labour-intensive tasks.

Why Use Robots in Moulding?

Let’s break down the top reasons why more manufacturers are adopting robotics in moulding operations:

1. Improved Productivity

Robots can operate 24/7 without fatigue, enabling round-the-clock production. They drastically reduce cycle times by executing tasks faster and more consistently than human operators.

2. Enhanced Precision

Robotic arms can repeat actions with incredible accuracy—down to fractions of a millimeter. This is crucial for achieving consistent part quality and avoiding costly defects.

3. Reduced Labor Costs

While the initial investment in robotic systems can be high, the return on investment (ROI) is typically fast due to reduced labor requirements and fewer production errors.

4. Increased Workplace Safety

Moulding processes often involve high temperatures, heavy machinery, and repetitive motion. Robots take over these hazardous tasks, protecting human workers from potential injury.

5. Consistency in Quality

In industries like automotive, aerospace, and medical, consistency is everything. Robots ensure that every part meets the same specifications, batch after batch.

Key Applications in Moulding

Here’s how robots are being applied across various moulding disciplines:

Plastic Injection Moulding

- Part Picking and Placing: Robots extract the finished parts without damaging the surface or internal structures.

- Insert Moulding: Automated placement of metal inserts before plastic injection.

- Sprue Removal: Clean and precise trimming of excess material.

Metal Die Casting

- Molten Metal Pouring: Robots handle molten metal with precision and safety.

- Component Removal: High-heat-resistant robots quickly remove cast parts to reduce cycle times.

Rubber Moulding

- Loading and Unloading: Speed up the process and reduce manual handling risks.

- Flash Trimming: Remove extra rubber for a clean, finished product.

Integration and Customisation

Modern robotic systems are built for seamless integration. They can connect with existing PLCs (Programmable Logic Controllers), sensors, and vision systems for intelligent decision-making. Many are also equipped with machine learning capabilities to improve performance over time.

Customisation is another advantage. You can choose from:

- 3-axis, 5-axis, or 6-axis robots

- SCARA or Cartesian systems

- EOATs (End-of-Arm Tools) tailored to specific tasks

Case Study: Boosting Efficiency with Robotics

A mid-sized automotive components manufacturer in Chennai implemented robotic part pickers for their plastic injection moulding machines. Within 3 months, they reported:

- A 30% increase in throughput

- 20% reduction in product defects

- Full ROI in under 10 months

By automating even just the part removal and trimming processes, the factory saw a massive improvement in output and overall operational control.

Challenges to Consider

Despite the benefits, manufacturers must address a few challenges:

- Initial Investment: Costs can be high, particularly for smaller operations.

- Skilled Workforce: Operators need training to manage and maintain robotic systems.

- Customisation Time: Tailoring robotic setups to unique processes may require careful planning.

However, with proper planning and a phased approach, even small to mid-sized enterprises (SMEs) can reap significant rewards.

The Future of Moulding Robotics

As technology evolves, so do the possibilities. We’re now seeing:

- AI-powered vision systems for real-time defect detection

- Collaborative robots (cobots) that safely work alongside humans

- IoT integration for real-time monitoring and predictive maintenance

The future is a smart, connected manufacturing ecosystem—and robots for moulding are central to it.

Conclusion

In a competitive manufacturing environment, standing still is not an option. Robots for moulding offer a powerful way to elevate production, reduce errors, and safeguard your workforce. Whether you're in plastic injection, metal casting, or rubber moulding, automation is no longer a luxury—it's a strategic necessity.

Invest in robotic moulding solutions today, and shape a future that’s faster, safer, and smarter.