Automation has redefined manufacturing. One of the most widely adopted technologies driving this transformation is the pick and place robot—a fast, reliable, and versatile solution that reduces cycle times, improves accuracy, and enhances workplace safety.

Whether it’s electronics assembly, food packaging, or warehouse logistics, pick and place robots are becoming the backbone of modern production lines.

What Is a Pick and Place Robot?

A pick and place robot is an industrial automation system programmed to pick up an object from one point and place it at another with extreme precision.

They are equipped with end effectors like:

- Suction cups for lightweight items

- Grippers for mechanical holding

- Magnetic tools for metal parts

And often paired with vision systems that detect object orientation and position for accurate placement.

Why Manufacturers Choose Pick and Place Robots

✅ Unmatched Speed

Robots can operate at high speeds without fatigue, significantly cutting production time.

✅ Superior Accuracy

Consistent handling ensures fewer rejects and better quality.

✅ 24/7 Operation

Robots can work continuously, meeting the demands of high-volume manufacturing.

✅ Multi-Product Capability

Easily reprogrammed for new tasks or product designs.

✅ Better Safety

Reduces repetitive strain injuries and keeps workers away from hazardous areas.

Where They’re Used

1. Electronics Manufacturing – Placing delicate microchips and resistors on PCBs.

2. Food & Beverage – Packing products into cartons while meeting hygiene standards.

3. Automotive – Handling gaskets, seals, and small assemblies.

4. Logistics & Warehousing – Sorting parcels for delivery.

5. Pharmaceuticals – Accurately packaging tablets and medical kits.

Delta Stark Engineering: Custom Pick and Place Solutions

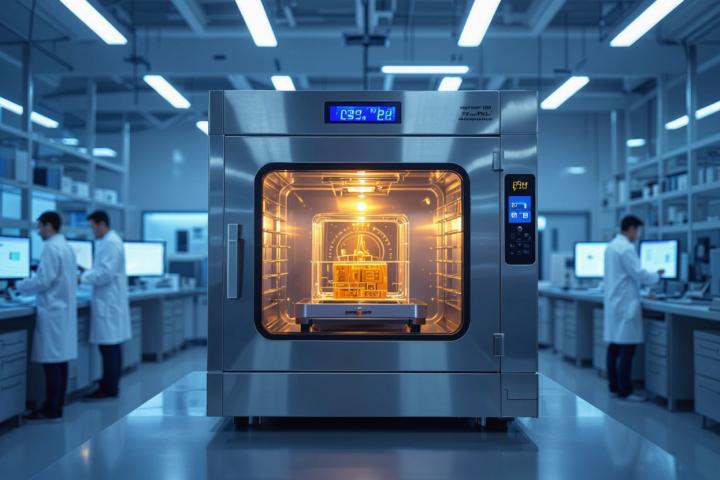

At Delta Stark Engineering, we build pick and place robots designed to fit your exact manufacturing needs.

Our systems offer:

- High-speed operation with servo-driven precision

- Advanced vision systems for accuracy

- Customizable grippers for different product shapes and sizes

- Easy integration with conveyors, packaging lines, and inspection systems

We serve industries across packaging, plastics, electronics, and more, delivering turnkey automation from design to installation.

Example: Packaging Industry Upgrade

A packaging company in Tamil Nadu installed our Delta Stark pick and place robot for loading containers onto conveyors. The result?

Cycle time reduced by 30%

Output increased by 20%

Labour costs dropped significantly

Let’s Build Your Automation Future

If you want to improve throughput, reduce waste, and meet growing production demands, a pick and place robot is a smart investment.