Introduction

In today’s fast-paced industrial landscape, manufacturers are under constant pressure to improve efficiency, cut costs, and maintain product quality. One automation solution that addresses all these challenges is the pick and place robot. Known for their speed, accuracy, and flexibility, pick and place robots are now widely used across industries to handle repetitive tasks with unmatched efficiency.

What are Pick and Place Robots?

Pick and place robots are robotic systems designed to lift items from one location and place them in another. They are equipped with robotic arms, sensors, and grippers to handle materials of various sizes, shapes, and weights.

These robots are commonly used for:

- Moving components on assembly lines

- Sorting and packaging products

- Stacking and palletising goods

- Handling delicate items in electronics or pharmaceuticals

Types of Pick and Place Robots

- Robotic Arm Pick and Place Systems: Multi-axis arms designed for flexible movements.

- Delta Robots: High-speed robots ideal for lightweight items in food and packaging.

- Collaborative Robots (Cobots): Work alongside humans safely, assisting in assembly and packaging tasks.

- SCARA Robots: Great for high-precision tasks such as electronics and semiconductor handling.

Benefits of Pick and Place Robots

- Increased Productivity – Operates continuously without breaks.

- High Accuracy – Ensures consistent handling and placement of products.

- Labor Savings – Reduces manual work in repetitive and monotonous tasks.

- Improved Workplace Safety – Handles heavy or hazardous materials.

- Flexibility – Easily reprogrammed to adapt to new tasks and products.

Applications of Pick and Place Robots

- Food and Beverage Industry – Packaging chocolates, snacks, and ready-to-eat meals.

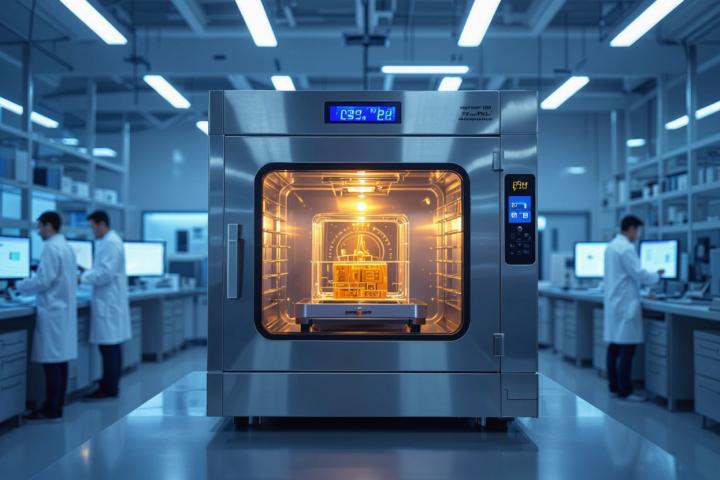

- Pharmaceutical Industry – Handling vials, syringes, and medicines in sterile environments.

- Automotive Industry – Moving and assembling parts with precision.

- Electronics Industry – Placement of delicate components like circuit boards and chips.

- Logistics and Warehousing – Sorting, stacking, and palletising items for shipping.

The Future of Pick and Place Robots

As industries move towards smart factories, pick and place robots will continue to evolve with:

- AI and Vision Systems – Smarter defect detection and adaptive learning.

- Collaborative Robotics – More human-robot synergy for improved workflows.

- IoT Integration – Real-time monitoring and predictive maintenance.

- Compact Designs – Suitable for small-scale and space-constrained facilities.

Delta Stark Engineering: Your Automation Partner

At Delta Stark Engineering, we specialize in designing advanced pick and place robots that deliver speed, accuracy, and reliability.

Our solutions include:

- High-performance robotic arms and delta robots

- Custom grippers for varied applications

- Seamless integration with existing production lines

- Comprehensive training and after-sales support

Whether it’s packaging, assembly, or material handling, we help industries achieve greater productivity with minimal downtime.

Conclusion

Pick and place robots are revolutionising modern manufacturing by reducing manual work, increasing speed, and ensuring product consistency. With companies like Delta Stark Engineering, businesses can embrace automation confidently and stay competitive in the global market.