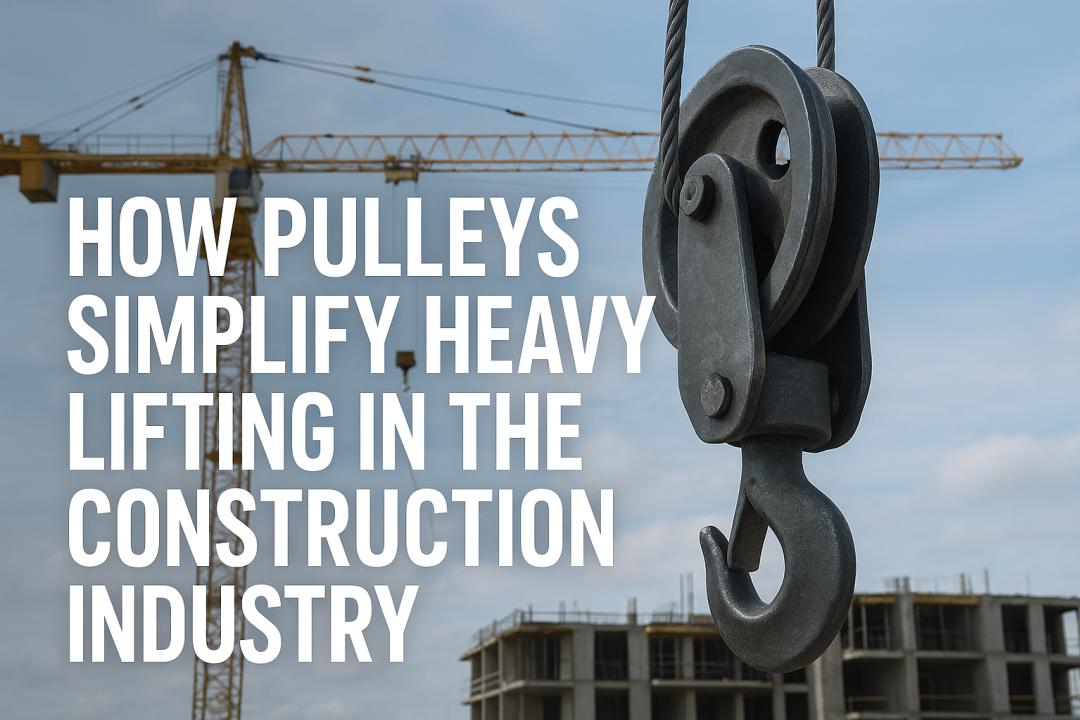

Efficiency and safety are vital to the fitness of the modern construction industry. The construction industry often requires reliable lifting mechanisms to be used in lifting steel beams or moving heavy construction materials. An ancient yet effective construction apparatus remains a pulley system. Even today, contractors and builders consider the utilization of pulleys to minimize effort, maximize productivity, and ensure safety for workers. An esteemed pulley manufacturer in Ghaziabad should extend quality and functional pulley systems meant for various construction purposes.

How Pulleys Operate

Pulleys are built around a simple principle of redirecting force. With a rope or a cable looped over or around a wheel, the pulley makes it possible to lift a heavy object with minimal effort. By combining how many pulleys are combined into a system (which we call 'block and tackle'), it can reduce the force needed to lift an object significantly. Not only does this help make lifting a more manageable task, but it also assists in moving a load both vertically and horizontally with greater control.

Advantages of Using Pulleys in Construction Projects

1. Decreased Human Effort

Simply speaking, the increased application of pulleys reduces the effort put forth by workers in lifting. A single pulley only redirects the force, yet multiple pulleys working simultaneously can halve the effort or more, thus leading to faster work on sites and less exhaustion for workers.

2. Improved Safety

Construction jobs are inherently hazardous, and safety must always be prioritized. A heavy load will be hoisted by a set of pulleys while allowing smooth and controlled lifting. This could help in preventing accidents arising out of slipping, falling, or an uncontrolled load. Maintenance of a secure pulley system will also prevent damage or the loss of expensive materials.

3. Accuracy in Hoisting and Placement

Pulleys offer more accurate and direct control of heavy loads than human effort. Placement of structural members, such as steel frames or concrete slabs, must be done in exact points under construction. The pulley system will assist in hoisting while ensuring the smooth operation, ultimately making accurate placement easier, while reducing costly pitfalls.

4. Cost-Effective Operations

Decreasing labor and time to shift and lift heavy commodities is how pulleys help in construction. This will increase efficiency, reduce labor costs, and keep projects on time, something paramount in this highly competitive construction world.

Types of Pulleys Commonly Used in Construction

- Fixed Pulley: Allows the force's direction to change so that the force is easier to pull heavy loads in a vertical upward motion.

- Movable Pulley: The movable pulley, while connected to a fixed point, changes the magnitude of the force required to perform work by distributing some of the weight elsewhere.

- Compound Pulley (Block and Tackle): The compound pulley is a combination of fixed and movable pulleys constructed so that a pulley block system can lift massive building materials.

Final Thoughts

Pulleys are still one of the most useful and practical things to have been developed within the construction field. They can be utilized to make lifting easier when moving heavy materials, which reduces risk and overall allows construction workers to finish projects more efficiently and safely. Pulleys can be used for a small-scale project or a larger-scale infrastructure project. Then, for durable and long-lasting performance, working alongside an experienced pulley manufacturer in Ghaziabad will allow construction companies to receive the best items to fulfill their needs.