Lighting design has evolved far beyond basic illumination. Today, lighting is expected to enhance aesthetics, improve functionality, and operate efficiently for years without failure. As these expectations rise, the technology behind LED strips continues to advance. One of the most important developments in recent years is COB LED strip technology, which has transformed how continuous and uniform lighting is achieved. Choosing the right COB LED strip factory plays a major role in ensuring this technology delivers its full potential.

From commercial interiors to architectural accents and retail displays, COB LED strips are increasingly favored for their smooth light output and professional appearance.

Understanding What Makes COB LED Strips Different

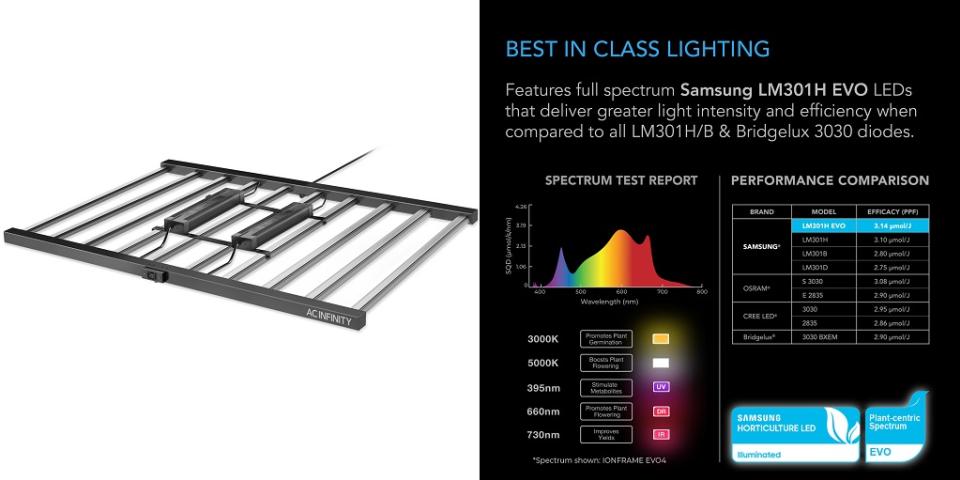

COB, or Chip-on-Board, LED strips differ from traditional SMD LED strips in how the LED chips are mounted. Instead of visible individual diodes, COB strips feature densely packed chips coated with a phosphor layer. This design creates a seamless line of light without visible dots.

This uniform illumination makes COB LED strips ideal for applications where visual comfort and elegance matter. Designers prefer them for indirect lighting, under-cabinet installations, and high-end commercial environments because they eliminate harsh glare and uneven brightness.

However, achieving this level of quality depends heavily on manufacturing precision. A reliable factory ensures correct chip density, stable phosphor coating, and consistent electrical performance across the entire strip.

Why Manufacturing Quality Matters in COB LED Strips

Not all COB LED strips are created equal. Manufacturing quality determines brightness consistency, color accuracy, heat dissipation, and long-term reliability. Poor production practices can result in uneven light, color shifts, and premature degradation.

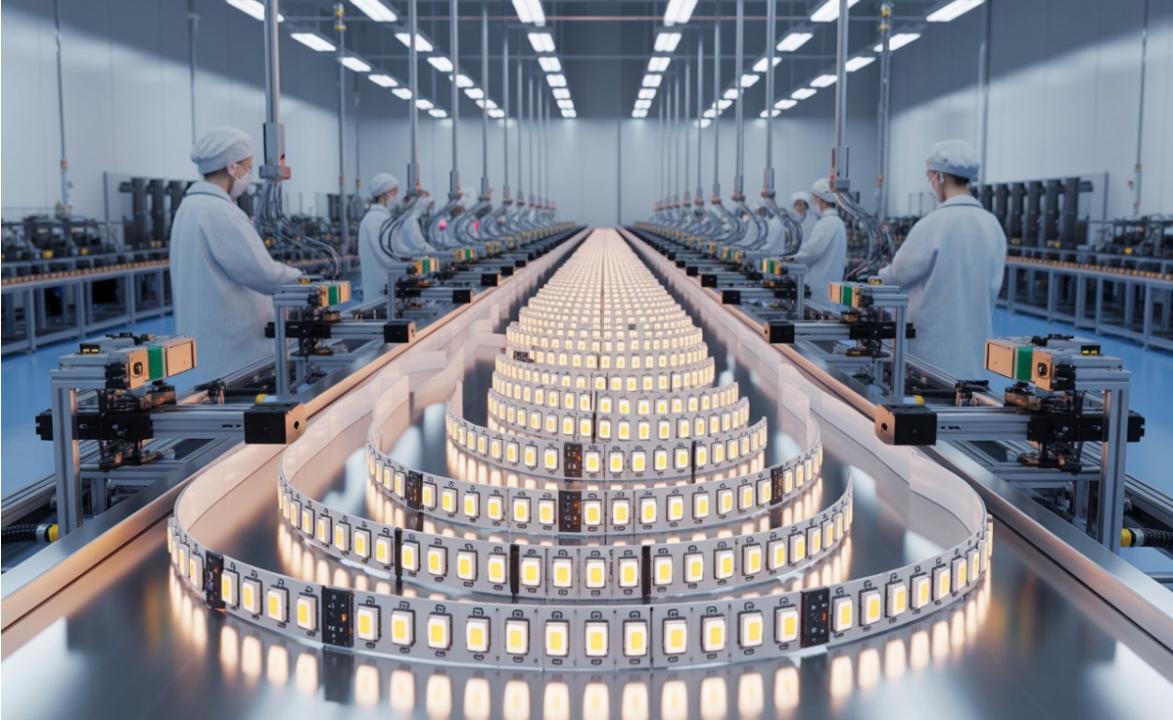

A professional cob led strip factory focuses on strict quality control at every stage of production. This includes careful LED chip selection, precise bonding processes, and thorough testing under real-world operating conditions.

Factories with strong engineering teams also invest in thermal management solutions. Proper heat control prevents LED chips from overheating, which directly extends lifespan and maintains consistent light output over time.

Applications That Benefit from COB LED Strip Technology

COB LED strips are widely used across industries where smooth illumination is essential. In hospitality spaces, they enhance ambience by creating soft, continuous lighting along ceilings, walls, and furniture edges. In retail stores, they improve product visibility without distracting hotspots.

Architectural lighting projects also rely on COB technology to highlight structural elements cleanly and evenly. The absence of visible LED points allows designers to integrate lighting seamlessly into modern designs.

Industrial and workspace environments benefit as well, as uniform lighting reduces eye strain and improves visual comfort for long working hours.

Role of LED Modules in Complete Lighting Systems

While LED strips provide linear illumination, many lighting systems also rely on LED modules for signage, display lighting, and accent applications. Modules are often used where directional lighting or compact placement is required.

Working with a trusted LED Module manufacturer ensures that LED modules meet the same quality standards as COB LED strips. When both components come from reliable manufacturing sources, system compatibility improves significantly.

LED modules are designed to deliver stable brightness, accurate colors, and long operational life. They are especially useful in backlit signs, channel letters, and decorative installations where consistent output is critical.

Integration Between COB LED Strips and LED Modules

In professional projects, COB LED strips and LED modules are often used together to achieve layered lighting effects. Strips provide continuous ambient lighting, while modules add focused illumination where needed.

When these components are engineered with similar electrical characteristics and quality standards, installation becomes easier and more reliable. Voltage matching, consistent color temperature, and compatible control systems reduce the risk of performance issues.

Manufacturers that offer both COB LED strips and LED modules are better positioned to support integrated lighting solutions, especially for large-scale or customized projects.

Reliability and Longevity in Commercial Installations

Commercial lighting installations demand durability. Downtime, maintenance, and replacements can be costly, especially in retail, hospitality, and public spaces. This is why sourcing from a dependable COB LED strip factory is essential.

High-quality COB LED strips are designed to maintain brightness and color stability over extended operating hours. Advanced encapsulation techniques protect the chips from moisture and dust, while robust PCB materials support mechanical stability.

Similarly, professionally manufactured LED modules are tested for electrical safety, heat resistance, and long-term performance, ensuring they remain reliable throughout their service life.

Customization Options for Specialized Projects

Every lighting project has unique requirements. Some demand specific color temperatures, others need flexible lengths or special mounting options. Leading factories offer customization services to meet these needs.

COB LED strips can be tailored for different brightness levels, beam spreads, and protection ratings. LED modules can be customized in shape, voltage, and lens design to fit specific signage or architectural elements.

Customization not only improves visual results but also enhances installation efficiency by reducing on-site modifications.

Energy Efficiency and Sustainability Benefits

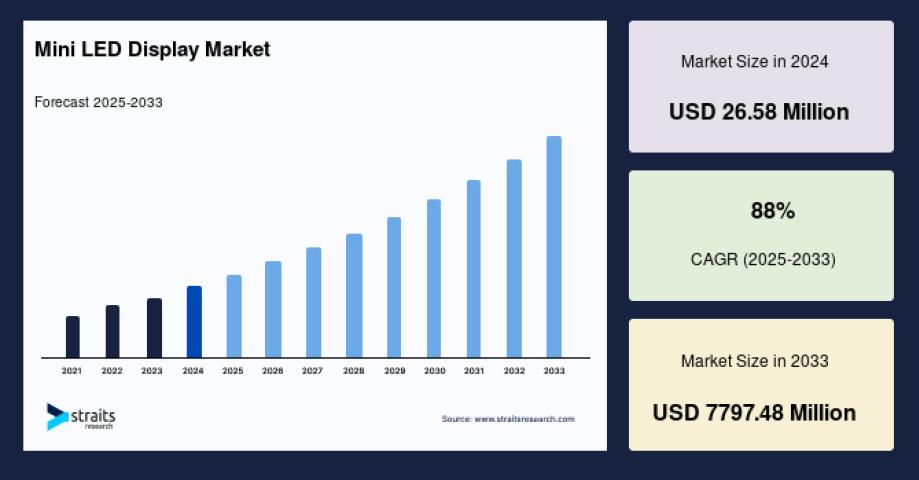

Energy efficiency is a major reason businesses switch to LED lighting. COB LED technology further improves efficiency by optimizing chip density and light distribution. Less energy is wasted, and more light reaches the intended area.

Professional factories also focus on reducing material waste and improving production efficiency. Longer-lasting LED strips and modules mean fewer replacements, lower energy consumption, and reduced environmental impact over time.

These sustainability benefits align with modern building standards and energy regulations, making high-quality LED solutions a smart long-term investment.

Final Thoughts

Selecting a reliable COB LED strip factory and LED module manufacturer is a strategic decision that affects lighting performance, installation success, and long-term value. Quality manufacturing ensures smooth illumination, stable performance, and durability across diverse applications.

By partnering with experienced manufacturers, businesses gain access to advanced technology, customization options, and consistent product quality. This foundation allows lighting projects to meet both aesthetic and functional goals with confidence.

As demand for professional-grade lighting continues to grow, investing in trusted manufacturing partners remains one of the most effective ways to stay competitive and deliver exceptional results.