Seamless Strength: The Art of Cast In-Situ Pavement Light Installation

Published: November 2025 | Leighton Buzzard, UK

When heritage meets heavy loads, cast in-situ pavement lights are the gold standard. Unlike precast panels, these are poured on-site over live vaults, delivering seamless integration, unmatched durability, and perfect historical accuracy.

At The Pavement Light Company Ltd, we’re one of just five UK specialists – and fewer worldwide – with the expertise to cast reinforced concrete pavement lights directly on your basement. From Mayfair townhouses to West End theatres, we rebuild what time has worn away.

Why Cast In-Situ? The Advantages That Matter

- Perfect for complex shapes – sloped pavements, irregular spans, curved vaults

- Heritage compliance – no removal of original iron frames or bearings

- Maximum load capacity – up to 75 kN concentrated load (BRE certified)

- Zero cold joints – monolithic pour prevents leaks

- Faster on-site completion – no transport delays, immediate curing

Explore precast vs in-situ options →

Our 5-Phase In-Situ Casting Process

1. Controlled Demolition & Waste Management

We cut and lift old panels section by section, using licensed waste carriers and dust-suppressed tools. Debris never enters your basement.

2. Precision Formwork & Lens Layout

Bearings are torch-dried and level-checked. We install custom formwork using original moulds to match historic lens sizes:

- 100mm × 100mm (standard concrete)

- 117mm half-shell (for paver integration)

- 93mm prismatic (repair inserts)

3. Hand-Cast Reinforced Concrete

We pour C40-grade concrete with embedded steel reinforcement, hand-troweled to exact falls. Lenses are aligned to ±2mm tolerance.

4. Heritage-Grade Sealing & Finishing

- Hot-pour bitumen joints or 45° mastic asphalt seals

- Carborundum grain topping for slip resistance

- Natural, coloured, or exposed aggregate finish to blend with surrounding paving

5. BRE Certification & Handover

Every panel is load-tested and issued a BRE certificate for fire, thermal, and structural compliance.

Walkable in 24–48 hours. Certified for life.

Weather-Smart Scheduling: When to Cast

Concrete cures best in spring and summer (3°C and rising, dry conditions).

In winter, we use:

- Insulated tarpaulins

- Hessian blankets

- Low-heat curing systems

Pro Tip: Book early – winter leak repairs spike demand.

Leak Prevention Built In

In-situ panels eliminate joint failures – the #1 cause of basement flooding.

For existing leaks, we offer:

- Emergency resealing with torch-applied bitumen

- Full waterproof membrane upgrades

Stop leaks before they start → Resealing & Waterproofing

Accreditations That Protect You

- BRE Certified – Fire, load, and thermal performance

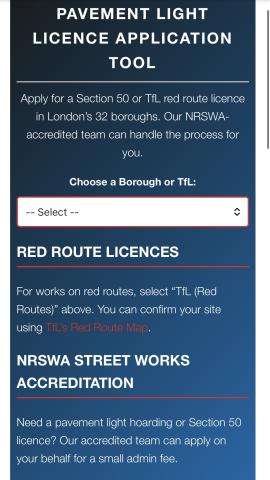

- NRSWA Accredited – Full street works compliance

- Licensed Waste Carriers – Environment Agency approved

- Council Licence Support – We handle hoarding permits

Need a pavement light licence? → Start here

Iconic Projects, Flawless Results

- Selfridges, Oxford Street – Full vault light replacement over live retail

- Royal Court Theatre – Sloped in-situ panels with damp-proofing

- Levi’s Flagship, Regent Street – 93mm lens integration

- Stella McCartney, Old Bond Street – Discreet heritage restoration

- Peter Pan Estate, W14 – Structural reinforcement + lens renewal

Frequently Asked Questions

Can you cast over a live basement?

Yes – with full propping and zero disruption to occupants.

How long before it’s walkable?

24–48 hours with standard curing; accelerated options available.

Do you match original lens patterns?

Yes – using original moulds for 100mm, 117mm, and heritage sizes.

What’s the maximum span?

Up to 4.4 metres with distributed loads to 20 kN/m².

Start Your In-Situ Project Today

From survey to certification, we manage every detail.

The Pavement Light Company Ltd

46 Westside, Dogget Street, Leighton Buzzard, LU7 1BE

📞 [01525 377513 – In-Situ Specialist Line]

📧 Request a free site survey

🕒 Open: Mon–Fri 9am–5pm | Sat by appointment

Built on site. Built to last. Built for London.

Explore Related Services:

Cast In-Situ Pavement Lights →

Heritage Glass Lens Replacement →

Emergency Resealing Services →

Victorian Cast Iron Restoration →

Pavement Light Licensing Help →

Full Service Overview →

What Are Pavement Lights? →

The Pavement Light Company Ltd – In-situ excellence. Heritage precision. London trusted.

Company No: 10749794 | Copyright © 2017–2025