Metal Baffle Ceilings have become synonymous with modern ceiling architecture, often seen in contemporary commercial spaces such as airports, corporate offices, retail centers, and public institutions. Their open linear structure allows flexibility in acoustic performance, airflow management, and lighting integration while offering a distinctive visual appeal. However, despite their engineered elegance, these ceilings are vulnerable to two critical issues: misalignment and sagging.

Understanding the cause of these issues and how to prevent them is vital to ensuring the long-term success of your ceiling installation. Whether you're an architect, contractor, or project stakeholder, mastering these aspects can mean the difference between flawless functionality and ongoing frustration.

Precision and Problem: Misalignment and Sagging Defined

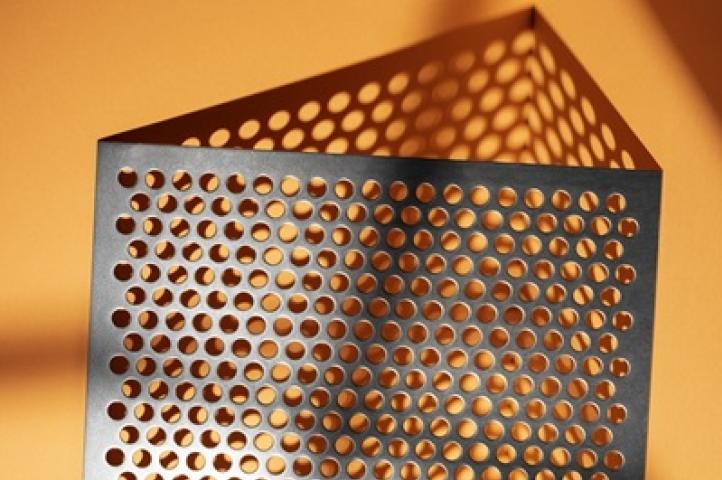

At first glance, Metal Baffle Ceilings seem simple and streamlined, but their proper installation requires technical precision. Misalignment refers to uneven baffle spacing or distorted linearity, which may occur due to incorrect measurements, structural movement, or grid layout inconsistencies. Over time, misaligned baffles not only disrupt visual harmony but can also affect the ceiling's acoustic efficiency.

Sagging is another subtle but serious challenge. This occurs when baffles begin to bend downward, usually under the influence of excessive weight, inadequate suspension systems, or thermal expansion. Left unchecked, sagging can evolve into a safety hazard or lead to full system failure. Recognizing these risks early and planning accordingly is the cornerstone of a robust and enduring ceiling system.

Precision Starts with Planning

Every flawless Metal Baffle Ceiling starts on the drawing board. Coordination between the architect, acoustical consultant, and ceiling manufacturer is crucial to defining baffle dimensions, grid spacing, support systems, and integrated services.

Key Planning Tips:

Coordinate ceiling height and baffle depth early: Ensure proper clearance from slabs and service ducts.

Account for movement joints and MEP penetrations: These influence layout continuity and structural stability.

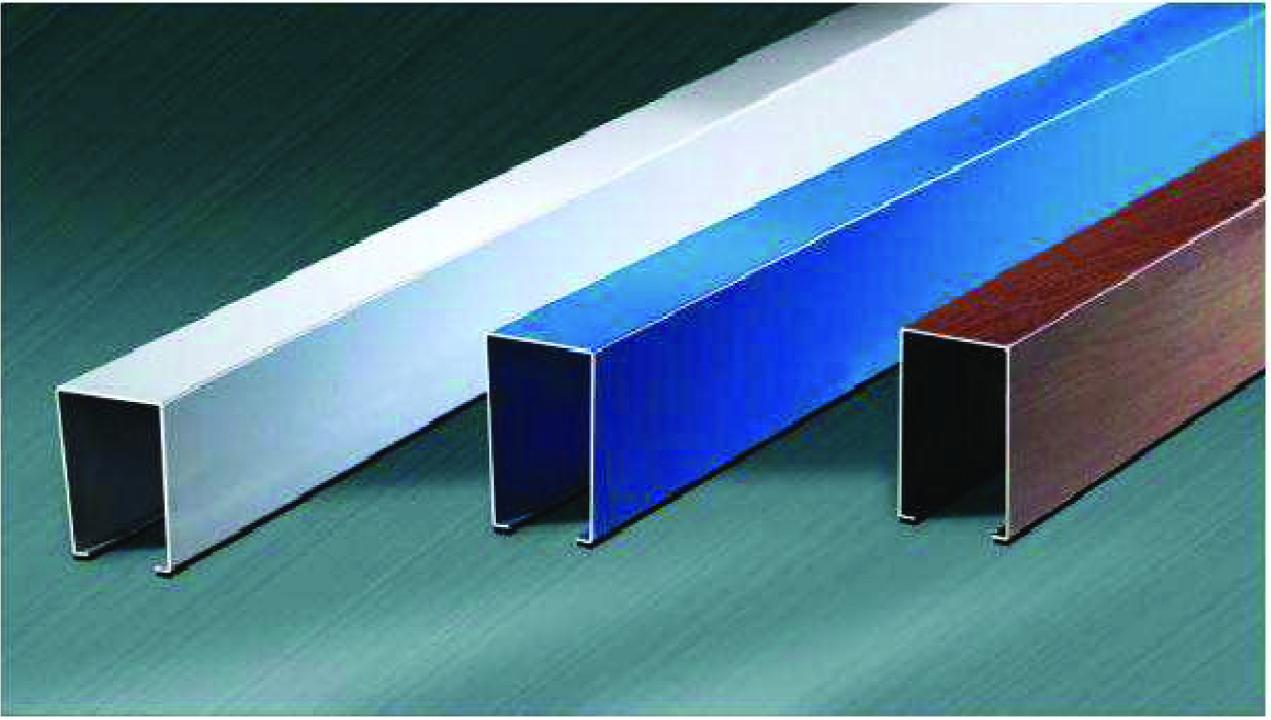

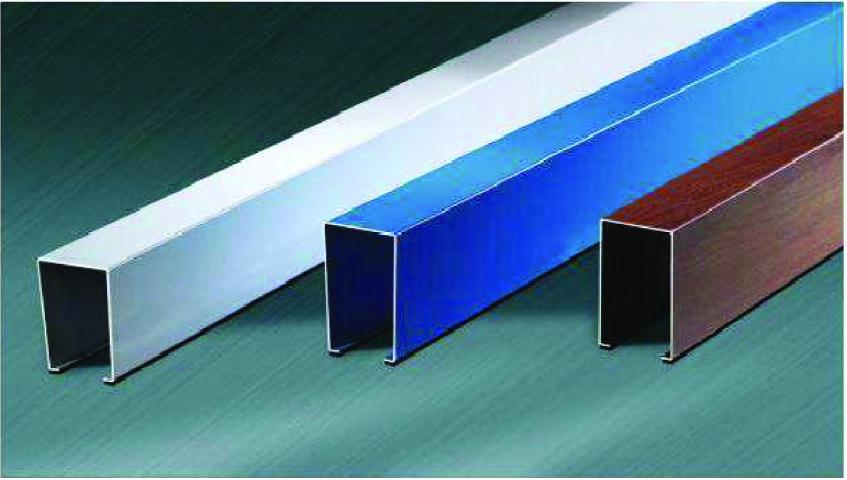

Specify the right gauge and finish: Thinner gauges may seem cost-effective but are more prone to deflection.

A detailed shop drawing review process will help catch conflicts between ceiling layout and other trades. Don’t skip this phase—it's where most alignment issues are born or prevented.

Design Intelligence is the First Line of Defense

Flawless ceiling systems begin long before installation—during the conceptual and technical planning phase. Designing a structurally stable Metal Baffle Ceiling requires more than choosing the right pattern or finish. It demands comprehensive coordination among design teams, acoustic consultants, structural engineers, and ceiling system suppliers.

Every element, from the ceiling height and baffle depth to fixture locations and HVAC penetrations, plays a role in alignment stability. For example, if ceiling services like lighting or ventilation aren't coordinated properly with the baffle grid, it can lead to obstructions that push baffles out of line. Similarly, choosing a metal thickness that doesn't support the required span can predispose baffles to bending under their own weight.

Material specifications must be based on actual usage demands, taking into account humidity levels, environmental temperature shifts, and the weight of integrated fixtures. Additionally, spatial tolerances around the perimeter need to be calculated to absorb subtle structural shifts without compromising alignment.

Craftsmanship in Action: Why Installation Techniques Matter?

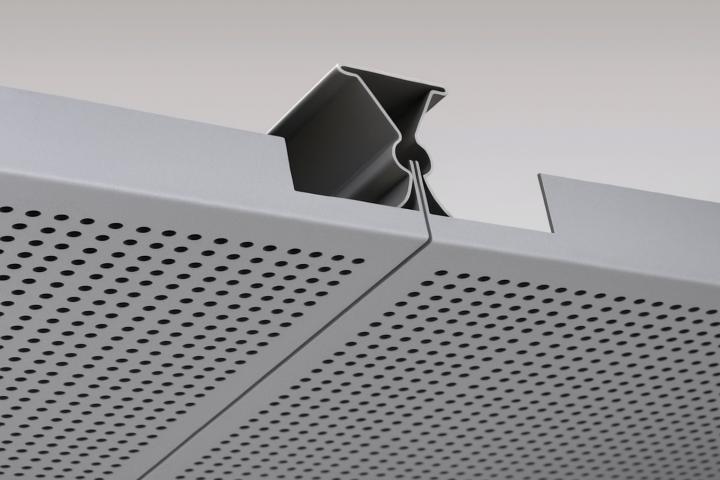

No matter how well a system is designed, poor installation can sabotage even the best products. With Metal Baffle Ceilings, accuracy during installation is non-negotiable. Each baffle must be suspended at the correct height and distance, maintaining precise spacing to ensure seamless visual flow.

Professional installers use laser-guided tools to align suspension points and ensure baffles remain level. The choice of suspension system also plays a critical role. Ceiling contractors must adhere strictly to the manufacturer’s recommendations regarding spacing and weight tolerance. Using substandard hangers or skipping alignment checks during installation can cause cumulative shifts that become more visible over time.

If your project involves a large area or high ceilings, consider engaging technical experts to oversee the alignment phase and ensure all specifications are accurately implemented on-site.

If you're exploring reliable acoustic ceiling systems with expert support, contact us to discuss your project in detail.

Managing Metal's Natural Tendencies: Thermal and Structural Behaviors

Metal is a dynamic material. It expands and contracts with temperature changes, and this natural behavior can influence the alignment of Metal Baffle Ceilings, especially in environments with extreme or fluctuating conditions. When this expansion isn’t anticipated during installation, the baffles may begin to warp or separate, creating uneven gaps or, worse, structural tension within the grid.

To mitigate such challenges, ceiling systems should be installed in climate-controlled environments whenever possible. Where this isn't feasible—like atriums or large public zones—it's critical to integrate movement joints and use flexible connections that allow for expansion without disturbing alignment.

Care must also be taken to prevent overly rigid perimeter fixing. Instead, allowing a calculated margin of movement at edges can absorb stress and protect the integrity of the entire ceiling system.

For large-scale projects in high-movement zones, working directly with ceiling system manufacturers is advisable. They can provide thermal performance guidelines specific to their Metal Baffle Ceilings, which makes all the difference in long-term durability.

Backbone Beneath the Beauty: Reliable Suspension Systems

While the baffles steal the show aesthetically, it’s the suspension system that holds everything together—literally. Inadequate support is the leading cause of sagging in Metal Baffle Ceilings. Often overlooked in budget planning or procurement stages, the strength and quality of the ceiling suspension grid can determine the success or failure of the entire ceiling plane.

Suspension rods must be placed at calculated intervals, ensuring they can bear both static loads and any additional imposed weight. Suspension systems engineered for pre-assembled modules can also streamline the process and reduce human error during installation.

For customized baffle ceiling assemblies tailored to your design and site conditions, visit our website to explore our full range of solutions.

Final Inspection and Ongoing Vigilance

A post-installation inspection is not just a formality—it’s your last chance to detect and correct any subtle errors before occupancy. Use this stage to recheck alignment, spacing uniformity, and levelness across the entire ceiling surface. If possible, conduct this inspection using both visual checks and tools like laser levels or digital straightedges.

After handover, regular ceiling maintenance every 6 to 12 months ensures long-term reliability. Even the most expertly installed Metal Baffle Ceilings can gradually shift due to building settlement or environmental exposure. Scheduled reviews can detect early signs of movement or wear, allowing for prompt corrective action.

Craft of Ceiling Perfection

When designed, installed, and maintained with precision, Metal Baffle Ceilings deliver not just architectural elegance but also consistent acoustic and structural performance. They enhance spatial rhythm, promote vertical openness, and meet functional demands in some of the most dynamic environments.

But this potential can only be fully realized when attention is paid to alignment and structural integrity—right from the design table to long after installation. Misalignment and sagging are preventable outcomes, not inevitable ones.