Introduction

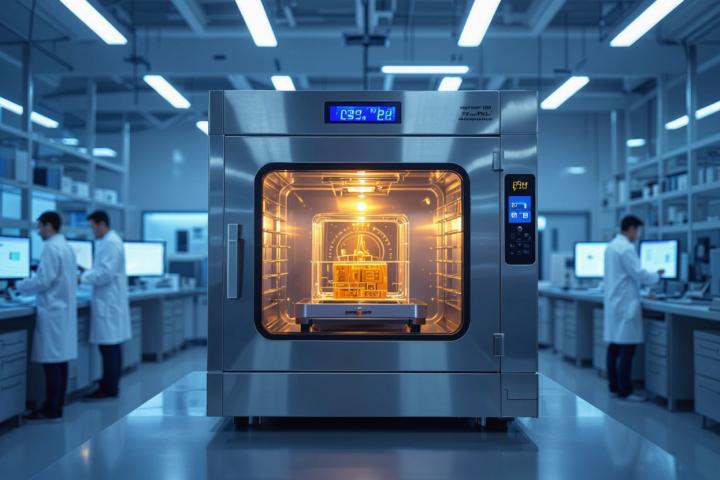

India’s manufacturing sector is undergoing a rapid transformation, and at the core of this change lies the rise of industrial robots in India. From automotive to electronics, packaging to pharmaceuticals, industrial robots are reshaping how businesses produce goods—making operations faster, safer, and more precise.

As government initiatives like Make in India and Industry 4.0 gain momentum, the adoption of industrial automation is no longer optional but essential for competitiveness. Companies like Delta Stark Engineering are leading this shift by delivering world-class robotic solutions tailored for Indian industries.

What Are Industrial Robots?

Industrial robots are automated machines designed to perform repetitive or complex tasks with precision and consistency. They are often used in manufacturing, assembly, welding, packaging, and material handling.

Common types include:

- Robotic Arms (6-Axis & 3-Axis) – Flexible automation for multiple applications.

- Pick and Place Robots – High-speed part handling for packaging and assembly.

- Welding Robots – Precision welding in automotive and heavy industries.

- Collaborative Robots (Cobots) – Designed to safely work alongside humans.

Growth of Industrial Robots in India

India is quickly becoming a major hub for robotics adoption. Key factors driving growth include:

- Rising labour costs and the need for efficiency.

- Global demand for high-quality, cost-effective products.

- Government support through initiatives like Production-Linked Incentive (PLI) schemes.

- SME adoption of affordable automation solutions.

According to industry reports, the market for industrial robots in India is expected to grow at double-digit rates over the next decade.

Applications of Industrial Robots in India

- Automotive Manufacturing: Welding, painting, and assembling car parts with precision.

- Electronics & Electrical: Handling delicate components and micro-assembly.

- Food & Beverages: Packaging, labelling, and palletising for high-volume production.

- Pharmaceuticals: Sterile handling and packaging of medical devices and drugs.

- Heavy Engineering & Metals: Cutting, grinding, and transporting heavy materials safely.

Benefits of Industrial Robots

- Increased Productivity – Operates 24/7 without fatigue.

- Precision & Quality – Minimises human error and ensures consistency.

- Safety Improvements – Reduces worker exposure to hazardous tasks.

- Cost Savings – Lower operational costs and reduced wastage.

- Flexibility – Reprogrammable for multiple applications.

Challenges in Adoption

Despite rapid growth, challenges remain for industries adopting robots:

- High Initial Costs – Investments may seem steep for SMEs.

- Skill Gaps – Shortage of trained engineers and operators.

- Integration Issues – Legacy systems may not easily sync with new robots.

- Awareness – Many businesses are unaware of the long-term ROI of automation.

The Future of Industrial Robots in India

The future of industrial robots in India is promising, with upcoming trends like:

- AI-driven robots for smarter decision-making.

- Cobots for safer human-machine collaboration.

- IoT integration for predictive maintenance.

- Compact, modular robots for SMEs.

These innovations will make robots more affordable, scalable, and essential for businesses of all sizes.

Why Delta Stark Engineering?

At Delta Stark Engineering, we provide world-class industrial robots in India designed for speed, reliability, and durability.

Our solutions include:

- Pick and place robots

- Moulding automation systems

- Packaging & material handling robots

- Custom robotic integration tailored to industries

With strong after-sales support, compliance expertise, and training programs, we ensure clients achieve maximum ROI from their automation investments.

📍 Based in Chennai | Serving Pan India

🌐 www.deltastark.com

Conclusion

The rise of industrial robots in India is redefining the manufacturing landscape. By embracing robotics, companies can enhance efficiency, meet global standards, and remain competitive in a fast-changing world.

With trusted partners like Delta Stark Engineering, industries can confidently step into the future of automation.