The installation of a metal false ceiling represents one of the most intellectually demanding exercises in interior architecture. It exists at the intersection of structural engineering, material science, and aesthetic philosophy. This suspended plane must achieve visual lightness while maintaining physical integrity.

It also helps to serve as an acoustic mediator while providing thermal regulation, and creates spatial definition while concealing mechanical complexity. The margin for error is measured in millimetres, and the consequences of miscalculation reverberate throughout the building's lifecycle. What follows is a systematic examination of the critical considerations for executing a flawless metal ceiling installation.

The Primacy of Comprehensive Pre-Installation Analysis

Before the first section of the runner is suspended, an exhaustive diagnostic of the overhead environment must be conducted. This preliminary phase establishes the foundational intelligence for the entire operation.

1. Structural Assessment: Conduct a thorough analysis of the substrate composition (concrete, steel deck, timber) and its load-bearing capacity. This determines the appropriate anchoring methodology and primary support point mapping.

2. Plenum Space Cataloguing: Create a detailed inventory of all mechanical, electrical, and plumbing components in the ceiling void. Utilise BIM modelling to identify and resolve potential conflicts between services and the proposed grid layout before installation begins.

3. Material Acclimatisation: Allow all metal components to stabilise in the installation environment for a minimum of 48 hours. This prevents thermal expansion/contraction issues and finish stress that can compromise the system's integrity.

4. Laser Projection: Establish the datum reference plane using laser levels throughout the space, accounting for any inherent slopes or undulations in the structural slab above.

The Geometry of Suspension: Mastering the Grid System

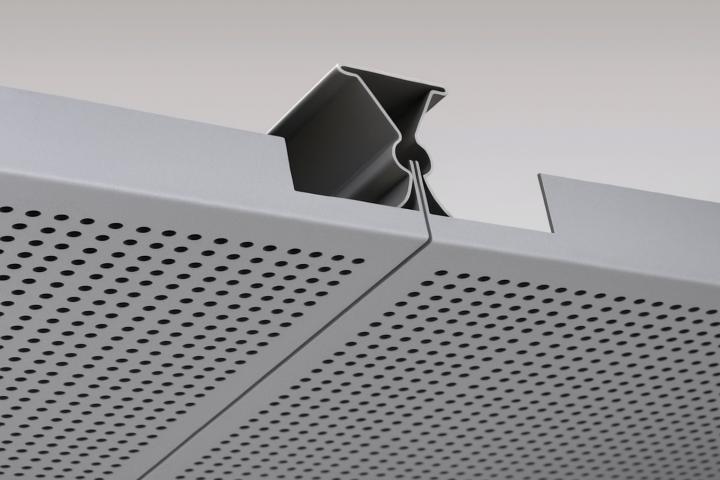

The concealed grid is the silent choreographer of the visible ceiling. Its installation demands geometric rigour and an understanding of static and dynamic loads.

- Primary Runner Orientation: Install primary runners perpendicular to the direction of the main ceiling panels to ensure proper support and load distribution across the grid system.

- Hanger Wire Calculations: Space hanger wires at engineered intervals that account for both the dead load of the ceiling system and potential live loads from maintenance activities.

- Proper Crimping Technique: Ensure hanger wires are correctly crimped to prevent failure under vibrational stress, using manufacturer-specified tools and methods.

- Seismic Compensation: In active seismic zones, install specialised perimeter moulding and swing->

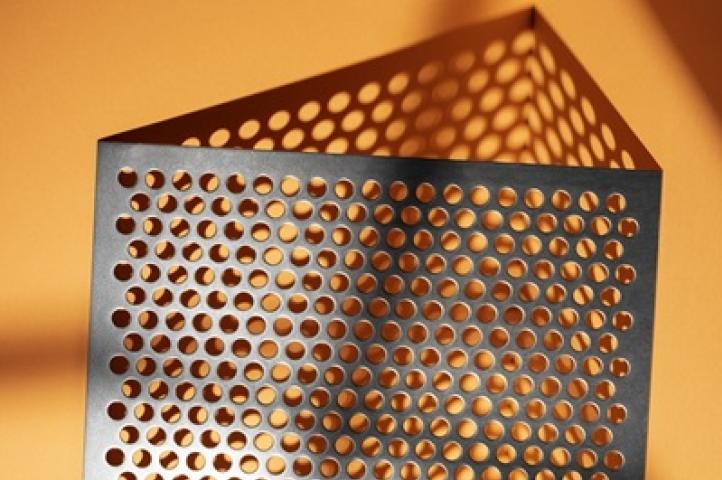

The Material Dialogue: Panel-to-Grid Interface and Acoustic Integration

The moment of panel placement represents the culmination of preceding preparations. The interface between the metal panel and the metal grid must be executed with precision to achieve both visual continuity and performance integrity.

1. Sequential Installation: Begin panel placement from a fixed starting point and work outward toward the perimeter, allowing cumulative dimensional tolerances to be absorbed at the edges with custom-cut panels.

2. Auditory Confirmation: Listen for the subtle click indicating proper panel seating in the grid system. Never force panels into position, as this distorts adjacent components and compromises system integrity.

3. Acoustic Layer Integrity: Ensure continuous, uncompressed acoustic insulation above perforated panels. Any gaps create acoustic short circuits that significantly diminish noise reduction performance.

4. Fleece Installation: Place acoustic fleece between panels and grid without folds or tears, as these imperfections create flanking paths for sound transmission.

The Art of Peripheral Detailing and Service Integration

The professional competence of an installation is most evident in its details, particularly at the interface with other building systems.

1. Expansion Gap Management: Maintain calculated perimeter gaps between the ceiling edge and surrounding walls to accommodate thermal expansion and contraction of the metal system.

2. Service Integration: Use custom-designed trim and mounting frames for light fixtures, air diffusers, and sprinkler heads to ensure seamless integration that respects both aesthetic and functional requirements.

3. Access Planning: Design and implement discrete access panels at critical service locations to facilitate maintenance without compromising the ceiling's visual continuity.

4. Transition Detailing: Employ specialised profiles and mouldings where the metal ceiling meets other materials or ceiling heights, ensuring clean visual transitions.

The Final Protocol: Verification and Documentation

The completion of physical installation should be followed by a rigorous quality assurance protocol and comprehensive documentation.

a. Lighting Condition Inspection: Conduct visual inspections under varied lighting conditions (morning, noon, artificial) to identify alignment imperfections or finish inconsistencies that might appear under specific lighting angles.

b. Service Access Verification: Confirm unobstructed access to all critical services above the ceiling, testing each access panel and ensuring maintenance pathways remain clear.

c. As-Built Documentation: Create detailed drawings that reflect the final installed condition, noting any deviations from the original design and the locations of all custom components.

d. Maintenance Register: Deliver a comprehensive register documenting custom panel sizes, unique conditions, and specific maintenance requirements for long-term facility management.

In conclusion, the successful installation of a metal false ceiling is a testament to disciplined methodology and technical foresight. It is an architectural ballet performed overhead, where every participant, from engineer to installer, must understand that the ultimate goal is not merely to suspend a ceiling, but to articulate a plane of refined order within the built environment. Through meticulous planning, precise execution, and thorough documentation, the metal false ceiling transcends its functional role to become an integral element of architectural excellence.