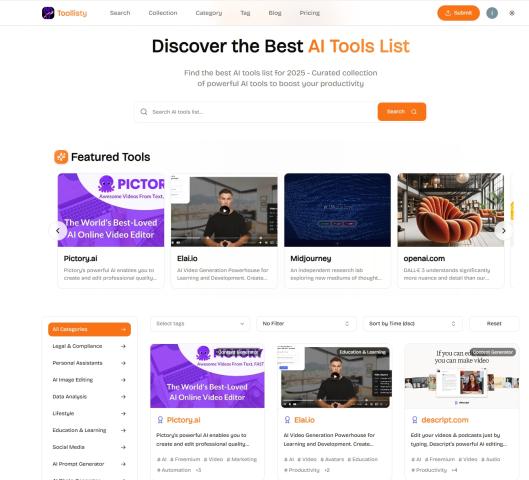

Precision boring serves as a fundamental aspect of contemporary manufacturing, crucial for producing precise, high-quality holes in a range of components. Nonetheless, the specifications for boring tools can vary greatly between industries because of differences in materials, tolerances, tool paths, and machine configurations. This blog examines how these elements affect the choice and use of boring tools in major industries like aerospace, automotive, medical devices, and electronics.

Aerospace: Micron-level precision

Materials and Tolerances

Aerospace components frequently employ advanced materials such as titanium, Inconel, and aluminium alloys. These materials are valued for their excellent strength-to-weight ratios, resistance to corrosion, and durability in extreme conditions like high altitudes or outer space. However, machining these alloys poses challenges — titanium and Inconel, for instance, are notoriously hard to machine due to their toughness and propensity to generate heat. This necessitates the use of boring tools crafted from highly wear-resistant materials, including coated carbide or polycrystalline diamond inserts.

Tolerances in aerospace manufacturing are exceptionally stringent, often within ±0.005 mm or even tighter. Such precision is vital to ensure that components fit seamlessly and operate reliably under stress, as even slight deviations can jeopardize safety and functionality. Aerospace parts typically undergo thorough quality inspections, including checks with coordinate measuring machines and non-destructive testing, to uphold these standards.

Tool paths and machine setups

The intricate nature of aerospace components often requires sophisticated machining techniques such as 5-axis CNC operations, which enable the tool to approach the workpiece from various angles. This is essential for parts like turbine blades, engine housings, and structural airframe components, which possess complex geometries.

Machines are generally outfitted with high-precision spindles and thermal compensation systems to mitigate heat expansion during extended cycles. Controlling vibration is crucial; boring bars designed to dampen vibrations or made from special alloys are utilized to avoid chatter, which can damage surface finishes and dimensional accuracy. Coolant delivery systems are frequently optimized to enhance heat dissipation, prolonging tool life and safeguarding costly workpieces.

Automotive: Speed and precision

Materials and tolerances

The automotive manufacturing industry primarily utilizes materials such as cast iron, aluminium alloys, and various grades of steel, including hardened and case-hardened types. Achieving efficient machining without early wear necessitates a careful balance between the toughness and sharpness of the tools used.

Although automotive tolerances are not as strict as those in aerospace, they are still vital — generally ranging from ±0.01 mm to ±0.02 mm — particularly for critical components like engine blocks, transmission housings, and suspension parts. Adhering to these tolerances is essential for ensuring that parts operate smoothly, thereby enhancing vehicle reliability and performance.

Tool paths and machine setups

The automotive industry’s focus on high-volume production requires the implementation of highly efficient tool paths that reduce cycle times and increase throughput. CNC machines equipped with automatic tool changers and multi-spindle configurations are prevalent, allowing for the simultaneous machining of multiple parts or features.

Boring tools typically incorporate replaceable inserts and modular designs, facilitating quick changeovers and maintenance. This modularity accommodates a range of hole sizes and depths without the need for entirely new tooling, thus minimizing downtime. Additionally, tools can be optimized for dry machining or reduced coolant usage, which helps lower environmental impact and costs.

Medical: Biocompatibility and precision

Materials and tolerances

The production of medical devices utilizes materials such as surgical-grade stainless steel, titanium, and cobalt-chrome alloys, selected for their biocompatibility and durability. It is essential to machine these materials to exact specifications, as implants and surgical tools must adhere to rigorous regulatory requirements and function reliably within the human body.

Tolerances in medical machining are exceptionally stringent, sometimes reaching as precise as ±0.002 mm. This level of accuracy ensures that implants fit seamlessly and operate as designed, thereby minimizing the likelihood of complications. The quality of the surface finish is also crucial to reduce tissue irritation and facilitate healing.

Tool paths and machine setups

The intricate size and complexity of numerous medical components necessitate the use of specialized micro-boring tools equipped with extremely sharp edges and low-friction coatings such as diamond-like carbon (DLC). High-speed spindles and sophisticated control systems allow for delicate operations with minimal tool deflection.

Machining typically takes place in cleanroom settings to comply with strict hygiene standards, requiring equipment that reduces contamination risks. Furthermore, many manufacturers of medical devices implement in-process inspection systems to guarantee that parts consistently meet high-quality standards throughout the manufacturing process.

Electronics: Micro-scale accuracy

Materials and tolerances

In the realm of electronics manufacturing, materials like copper, aluminium, and various engineering plastics are frequently utilized. The miniaturization of components necessitates extremely tight machining tolerances, often within ±0.005 mm or even better. Minor deviations can lead to electrical failures or assembly complications.

Given the fragility of electronic components, machining processes must be conducted in a manner that avoids introducing stress or heat that could potentially harm sensitive parts.

Tool paths and machine setups

Micro-machining techniques utilizing ultra-high-speed spindles and precision boring tools are implemented to achieve the required accuracy. Machines must be adept at performing delicate operations, often employing air or mist cooling to avert thermal distortion.

Automation and in-process inspection systems are typically integrated to guarantee consistent quality and minimize human error. Tools are engineered for easy replacement and reduced setup times to sustain high production rates.

The requirements for boring tools are significantly specific to each industry, shaped by elements like material characteristics, necessary tolerances, tool trajectories, and machine setups. Understanding these details is essential for choosing the right tools and attaining the best manufacturing results. As industries progress, the need for tailored boring solutions will increase, fostering advancements in tool design and usage.

For manufacturers seeking high-quality boring tools in Pune and beyond, FineTech Toolings offers industry-specific solutions tailored to aerospace, automotive, medical, and electronics applications. With advanced tool designs, reliable reconditioning services, and regional support, FineTech Toolings helps precision manufacturers enhance output, maintain quality, and stay competitive in today’s fast-evolving production environments.

Resource: Read more