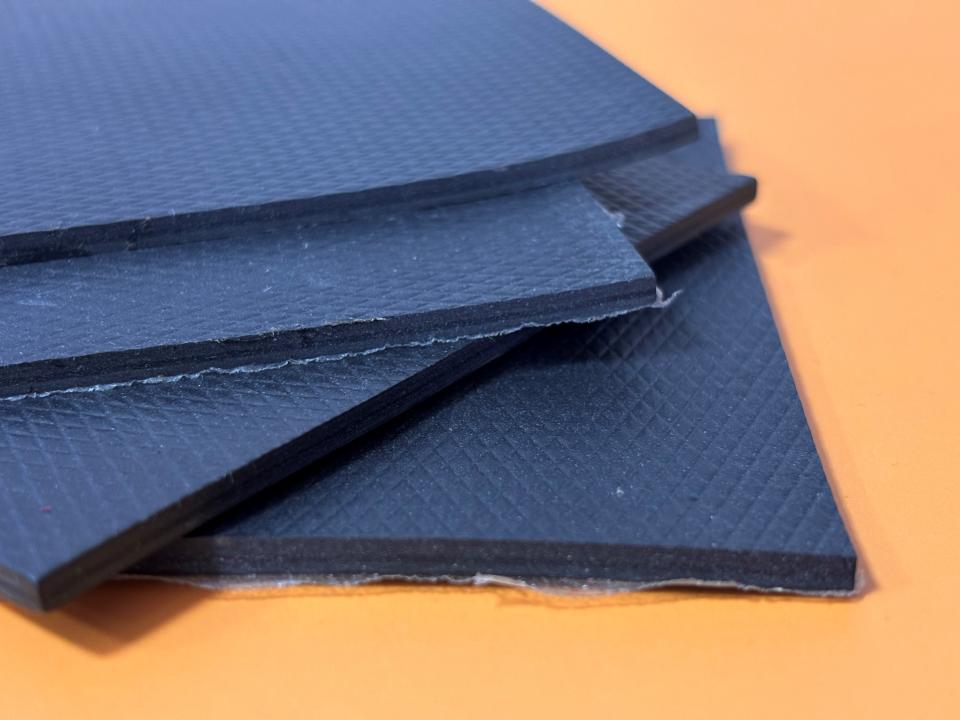

Mass loaded vinyl has served the needs of soundproofing for a number of years. But today, acoustic sheet material is taking a strong lead. Builders and designers now focus on performance, cost-effectiveness, and sustainability. This shift pushes acoustic sheet material into the spotlight. Let’s explore how both options compare across key factors.

Material Pricing and Delivery

Mass loaded vinyl is priced higher per square foot. Shipping costs also rise due to its weight. On the other hand, acoustic sheet material is lighter and more compact. That makes delivery more affordable. Bulk orders further reduce its unit cost for large projects. The best part is the rate of affordability. This is because it opens up possibilities for projects previously constrained by tight acoustic budgets.

Installation Expenses

MLV requires extra support and skilled handling. Labor charges often go up as a result. Acoustic sheet material installs quickly using basic tools. This reduces both time and labor fees. For short-deadline builds, this becomes a major advantage.

Its clean installation also lowers the need for post-job cleanup. That saves money and helps contractors stay on schedule. Smaller teams can complete more tasks with fewer resources. Solely because of its flexibility and ease of use, even compact remodeling tasks can benefit from it.

Suitability

Application: MLV is best suited for industrial or mechanical environments. It performs well in machine rooms or near HVAC equipment. Acoustic sheet material works better in people-centric spaces. Meeting rooms, classrooms, and media rooms see optimal results. It improves clarity without adding mass.

Soundscapes in collaborative environments require a delicate form of tuning. The lightweight nature of acoustic sheet material provides just the right touch. It enables better communication and reduces auditory fatigue, especially in places with continuous speech or discussion.

Integration with Other Surfaces

Acoustic sheet material can be layered under panels or fabrics. It combines well with acoustic treatment materials. MLV often needs to be hidden inside walls. Its bulky nature limits creative integration. Designers prefer the flexibility of layered acoustic systems.

In open ceilings or modern partitioning, designers increasingly need sound solutions. Especially those that add a high range of visual value. Apart from that, Acoustic sheet material supports layered installations and mixed finishes. It’s innovative wall treatments all without sacrificing performance, delivering the best that is known to mankind.

Visual Integration

MLV is purely functional. It’s not meant for display or exposed surfaces. Acoustic sheet material can be >

Its versatility in aesthetic integration helps preserve the interior concept. Especially while addressing a wide range of acoustic goals. This can include bold tones, minimal finishes, or natural fibers. All of this can essentially be a part of its vast range of design vocabulary.

Compatibility with Panels and Walls

The rise of acoustic wall panels shows a growing preference for design-forward solutions. Acoustic sheet material fits easily behind or between panels. It also pairs well with acoustic panel material in modular systems. MLV does not support this kind of layered creativity.

This compatibility with other acoustic components helps architects standardize modular systems. This is done without compromising flexibility. Such systems can be expanded, reconfigured, or relocated easily. All of it is essential for dynamic spaces.

Maintenance and Cleaning

MLV is stable but may shift over time if not secured well. Repairs often involve opening up walls or ceilings. Acoustic sheet material can be removed and replaced with ease. Some types are washable or stain-resistant, adding more utility.

For environments like schools, clinics, and studios, quick maintenance is everything. This is to be prioritised for the low upkeep nature of these materials. This makes them a practical choice across sectors.

Durability in Various Conditions

Both options perform well under normal indoor conditions. However, acoustic sheet material resists moisture and sagging when properly installed. It also aligns with newer acoustic treatment materials that emphasize long-term value.

Composition and Recycling

Mass loaded vinyl contains PVC and other synthetic compounds. Its recyclability is limited. In contrast, acoustic sheet material often uses recycled plastic or natural fibers. This makes it better suited for green building certifications.

Indoor Air Quality

The construction industry is prioritizing health and wellness. MLV may emit VOCs during installation. Acoustic sheet material is often low-emission. When paired with breathable acoustic material, it supports clean indoor environments.

Which One Offers More?

The decision depends on the space and goals. For strict sound isolation in technical zones, MLV still works well. But for modern, people-focused interiors, acoustic sheet material is the smarter option. It combines absorption, aesthetics, and affordability.

Acoustic sheet material is also more compatible with evolving design needs. It blends with acoustic panel material and acoustic wall panels effortlessly. This makes it future-ready and design-flexible. Its growing presence in architecture confirms its staying power. Overall, it represents the next generation of smart acoustic solutions—functional, beautiful, and future-conscious. Explore more : https://www.tranquilglobal.com/index.html