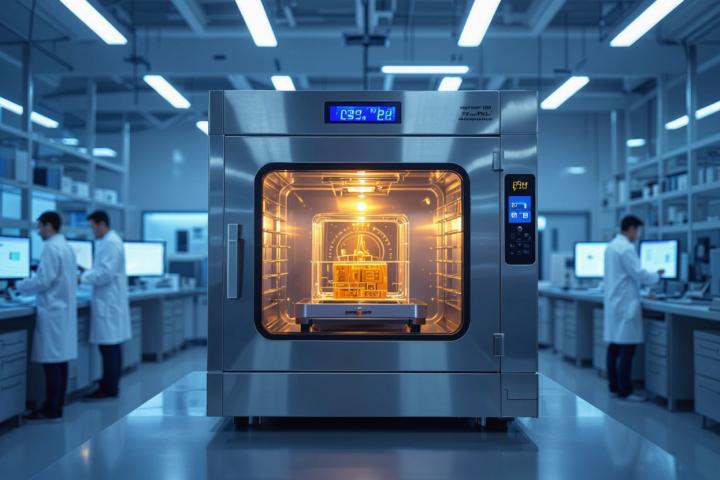

From automated food processing lines to intelligent packaging and sorting, robotics in the food industry is no longer a futuristic concept—it’s today’s reality. As food manufacturers face increasing demands for hygiene, efficiency, and customisation, robotics offers innovative solutions to streamline operations and maintain consistent product quality.

In this blog, we’ll explore how robotics is reshaping the food sector, the types of robots used, key benefits, and future trends to watch.

Why Robotics Matters in Food Processing

The food industry is under pressure to produce more—faster, cleaner, and with fewer human errors. Robots fill this gap by delivering:

- Precision in cutting, slicing, and portioning

- Speed in handling and packaging

- Safety through reduced human contact

- Consistency across production batches

In sectors where hygiene and contamination risks are high, such as meat or dairy, automation becomes a critical asset.

Key Applications of Robotics in the Food Industry

- Pick and Place Robots: These are the most widely used robots in food manufacturing. They pick items like biscuits, fruits, or candies from one location and place them into trays, boxes, or on conveyors. High-speed vision systems enhance their accuracy.

- Packaging and Palletising: Robots can package products in multiple formats—vacuum-sealed, boxed, or wrapped—and stack them for shipping. This reduces labour costs and speeds up delivery.

- Sorting and Quality Inspection: Equipped with vision sensors, robots can detect defects in products like bruised apples or broken cookies, removing them from the line to maintain quality standards.

- Cutting and Portioning: In the meat and seafood industries, robotic arms equipped with knives or lasers perform high-precision cutting, improving yield and minimizing waste.

- Cooking and Dispensing: In fast-food chains and commercial kitchens, robots are now used for flipping burgers, frying, and dispensing sauces in exact quantities.

Benefits of Using Robots in Food Processing

Enhanced Hygiene: Reduced human contact minimises contamination.

Operational Efficiency: 24/7 operations without fatigue.

Better Packaging Precision: Standardised output and reduced material waste.

Labour Cost Savings: Automation fills gaps due to labour shortages.

Increased Throughput: Faster production without compromising quality.

Challenges in Adopting Food Robotics

While the benefits are compelling, integrating robots into the food industry isn't without its challenges:

High Initial Investment: Setting up automation can be capital-intensive.

Customisation Needs: Food items vary in shape, size, and texture.

Cleaning Requirements: Robots need to withstand washdowns and remain compliant with food safety standards.

Training & Maintenance: Skilled personnel are required for maintenance and troubleshooting.

Types of Robots Used in the Food Industry

| Robot Type | Function |

|---|---|

| Pick & Place Robots | Sorting, placing, packaging |

| Delta Robots | High-speed applications (e.g., bakery items) |

| SCARA Robots | Small assembly tasks and light packaging |

| Articulated Robots | Complex motions like cutting, lifting |

| Cobots (Collaborative) | Work alongside humans in confined spaces |

Industries Benefiting from Food Robotics

- Dairy Processing: Cheese slicing, yoghurt filling

- Baking Industry: Dough handling, tray loading

- Meat & Seafood: Precision cutting, sorting

- Confectionery: Chocolate decorating, candy packing

- Ready-to-Eat Meals: Multi-component portioning, sealing

Real-World Example: Robotics in an Indian Food Plant

A leading snack manufacturer in India recently adopted delta robots to automate the packing of potato chips. The robots pick chips from the conveyor and place them into pre-formed pouches. The result? A 40% increase in output, reduced human contact, and consistent weight across packages—helping the brand meet rising demands during festive seasons.

The Future of Robotics in the Food Industry

The future promises more AI-powered robots with real-time decision-making capabilities, IoT integration for predictive maintenance, and autonomous mobile robots (AMRs) for warehouse movement.

Trends to watch:

- AI + Vision Tech: Detect ripeness, defects, or labelling errors

- Smart Factories: Robots connected to cloud systems for real-time control

- Machine Learning: Self-improving robots through production data analysis

Final Thoughts

The integration of robotics in the food industry is driving a revolution—from field to fork. It’s not just about automating tasks; it’s about redefining productivity, safety, and quality in food manufacturing.

As the world leans toward cleaner, faster, and safer food production, the use of robots will only continue to grow. For food businesses in India and around the world, now is the time to invest in the future of automation.

Are you a food business looking to upgrade your production line with robotics? Start exploring manufacturers and automation partners today. Embrace the change, and stay ahead in a competitive, quality-driven market.