Acoustic wood wall panels combine natural beauty with practical sound control, making them a popular choice for offices, homes, studios, and commercial spaces. However, their unique textured surfaces and porous wood materials require specific cleaning approaches to maintain both their aesthetic appeal and acoustic performance. Unlike standard wall surfaces, these panels demand careful handling to preserve their sound-absorbing qualities while keeping them looking their best.

Understanding Your Acoustic Wood Panels

Before beginning any cleaning process, it's crucial to understand what you're working with. Acoustic wood panels come in several varieties, each with specific cleaning requirements:

- Natural wood veneer panels feature real wood surfaces that require wood-specific cleaners

- Lacquered or sealed wood panels have protective coatings that allow for easier cleaning

- Unsealed or oiled wood panels need specialized wood oil treatments

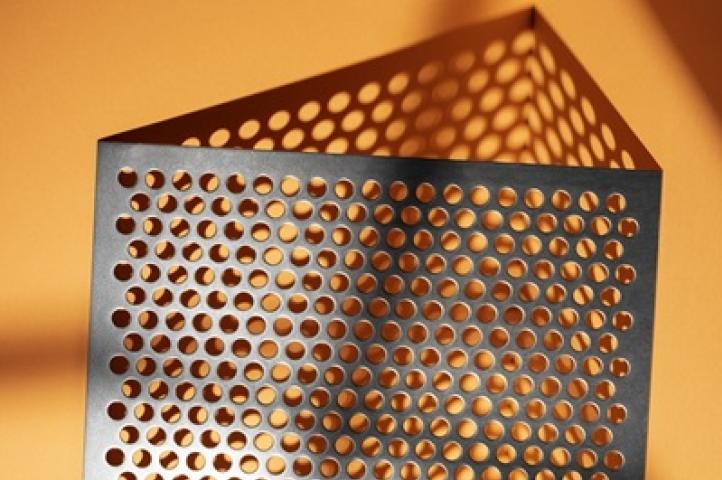

- Perforated wood panels contain numerous small holes that can trap dust and require special attention

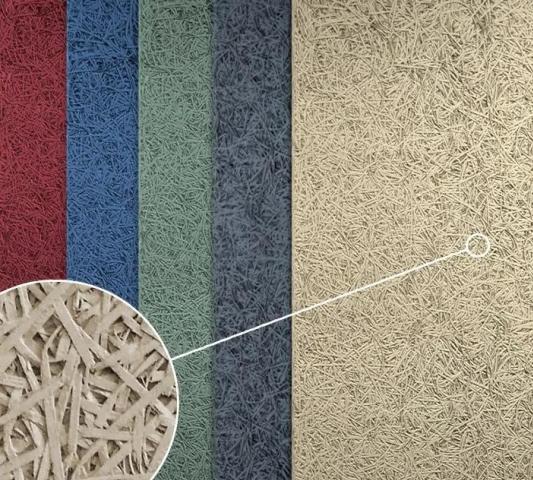

- 3D textured panels have intricate surfaces that demand careful dusting techniques

Daily and Weekly Maintenance Routines

Regular maintenance prevents dirt buildup and maintains your panels' appearance with minimal effort.

Dusting Techniques

Proper dusting forms the foundation of acoustic panel care. Use a soft-bristled brush attachment on your vacuum cleaner, setting it to low suction. Gently move across the panel surfaces in consistent directions. For textured or perforated panels, use a makeup brush or soft paintbrush to dislodge dust from crevices and holes. Microfiber cloths work well for smooth surfaces, while lambswool dusters effectively capture dust from textured finishes.

Preventive Measures

Place mats near room entrances to reduce dirt tracked into the space. Maintain proper humidity levels between 40-50% to prevent wood expansion or cracking. Keep panels away from direct sunlight using curtains or UV-protective window films to prevent fading. Establish no-smoking policies near acoustic panels to prevent resin and tar buildup.

Monthly Deep Cleaning Procedures

Some of the deep cleaning procedures are as follows:

Surface Cleaning Solutions

Create a cleaning solution using 1/4 cup white vinegar mixed with 2 cups distilled water. For tougher cleaning needs, mix 1 teaspoon of mild dish soap (pH-neutral) with 2 cups of warm water. Always test cleaning solutions on an inconspicuous area first.

Dampen a soft cloth with your chosen solution, wringing it thoroughly until it's barely moist. Wipe panels following the wood grain direction, working in small sections. Immediately dry with a separate clean, soft cloth to prevent moisture damage.

Spot Cleaning Strategies

For water-based stains, use a slightly dampened microfiber cloth with your cleaning solution. Gently blot the area rather than rubbing. Oil-based stains may require a small amount of rubbing alcohol applied with a cotton swab. Ink marks often respond to art gum erasers or specialized wood cleaners. Always work from the outside of the stain toward the center to prevent spreading.

Quarterly Comprehensive Cleaning

Some of the quarterly forms of comprehensive cleaning are as follows:

Deep Cleaning Process

Every three months, perform a more thorough cleaning. Begin with detailed vacuuming using brush attachments. Mix a fresh batch of cleaning solution, using distilled water to prevent mineral deposits. Work systematically from the top of the wall downward, cleaning one panel at a time. Pay special attention to corners and edges where dust accumulates. For perforated panels, use compressed air cans to blow dust out of the holes before vacuuming.

Conditioning Treatments

Unsealed wood panels benefit from occasional conditioning. Use wood-specific products like linseed oil or commercial wood conditioners. Apply minimally with a soft cloth, following product instructions carefully. Allow the treatment to absorb completely before buffing with a clean cloth.

Addressing Specific Cleaning Challenges

Some of the specific cleaning challenges are as follows:

Grease and Kitchen Splatters

In kitchen areas, grease buildup requires special attention. Create a paste from baking soda and water, applying it to greasy areas with a soft cloth. Let it sit for 5-10 minutes before gently wiping away. Follow with your standard cleaning solution to remove residue.

Smoke and Odor Removal

Smoke particles embed deeply into wood surfaces. Use an ozone generator for severe smoke damage, or try placing activated charcoal near affected panels. For surface smoke residue, wipe with a vinegar solution and place baking soda containers nearby to absorb odors.

Mold and Mildew Treatment

For minor mold issues, mix 1 teaspoon of tea tree oil with 1 cup of water in a spray bottle. Lightly mist the affected area and wipe clean after 10 minutes. Ensure proper ventilation and address moisture sources to prevent recurrence.

Professional Cleaning Considerations

Some situations warrant professional intervention:

- Extensive water damage affecting multiple panels

- Significant mold growth covering large areas

- Historic or valuable antique wood panels

- Unknown wood types requiring specialized care

- Severe smoke or fire damage restoration

- Protective Measures and Long-Term Maintenance

Protective Coatings

Consider applying protective coatings to new panels or after deep cleaning. Water-based polyurethane provides excellent protection while maintaining wood appearance. Always test coatings on small areas first and ensure proper ventilation during application.

Regular Inspection Routine

Monthly, inspect panels for:

- Changes in color or finish

- Warping or swelling

- Loose mounting hardware

- Mold or moisture signs

- Surface scratches or damage

Documentation and Care Log

Maintain a cleaning log noting:

- Cleaning dates and methods used

- Products that worked well

- Areas requiring special attention

- Seasonal changes in cleaning needs

- Professional service dates and treatments

Essential Don'ts for Acoustic Wood Panel Care

Never use these cleaning approaches:

- Abrasive cleaners or scouring pads

- Ammonia-based products

- Silicone-based furniture polishes

- Excessive water or liquid cleaners

- Steam cleaners or high-heat devices

- Harsh chemical solvents

- Pressure washers or high-pressure sprayers

Seasonal Care Considerations

Some of the care considerations are as follows:

Winter Months

During heating season, wood panels may contract. Increase humidity levels and inspect for new gaps or cracks. Dust more frequently as heating systems circulate more airborne particles.

Summer Season

Higher humidity may cause wood expansion. Ensure proper air circulation and monitor for moisture buildup. Use dehumidifiers in particularly damp conditions.

Creating Your Cleaning Toolkit

Assemble these essential cleaning supplies:

- Soft-bristled vacuum attachments

- Microfiber cloths (multiple colors for different tasks)

- Natural bristle brushes in various sizes

- pH-neutral wood cleaner

- White vinegar and distilled water

- Baking soda and mild dish soap

- Cotton swabs and soft sponges

- Wood conditioner appropriate for your panel type

- Clean, lint-free towels for drying

Maintaining Acoustic Performance

Remember that proper cleaning maintains both appearance and sound absorption qualities. Avoid clogging perforations with cleaning products. Never apply thick coatings that might reduce sound penetration. Ensure cleaning doesn't compromise the panel's acoustic properties by testing sound absorption after major cleaning sessions.

Establishing a Maintenance Schedule

Create a consistent cleaning routine:

- Daily: Visual inspection for obvious issues

- Weekly: Dust all panel surfaces

- Monthly: Light cleaning with appropriate solutions

- Quarterly: Deep cleaning and conditioning

- Annually: Professional assessment and maintenance

By following these comprehensive cleaning guidelines, your acoustic wood wall panels will maintain their beauty and functionality for years. Regular, proper care prevents major issues and preserves the investment in your acoustic environment. The key lies in consistent maintenance using appropriate methods and products specific to your particular wood panel type.