The global building materials industry has seen its fair share of disruptions in recent years, but few have been as consistently challenging as the ongoing shortage of raw materials. Among the affected sectors, the market for Acoustic Wood Panels has faced unique pressures. Architects, designers, and manufacturers alike are grappling with rising costs, extended lead times, and sourcing difficulties, especially for premium timber and sustainable wood varieties. As demand for aesthetically appealing and acoustically efficient interiors continues to rise, the scarcity of raw materials for Wood Acoustic Paneling presents both a challenge and an opportunity for innovation.

Perfect Storm: What’s Driving the Shortage of Materials?

To understand the ripple effects in the Wooden Acoustic Panels market, it’s crucial to first examine the root causes of the raw material crunch. Multiple factors have converged:

1. Supply Chain Disruptions

The COVID-19 pandemic brought international supply chains to a grinding halt. Timber-producing countries experienced labor shortages, restrictions on transportation, and temporary closures of sawmills, leading to a significant drop in wood availability. Even now, many supply chains have not fully recovered.

2. Environmental Regulations and Deforestation Laws

With rising global awareness of climate change and sustainability, governments have tightened regulations on logging and wood harvesting. While these are important steps toward environmental conservation, they have restricted access to certain wood types commonly used in Wood Acoustic Paneling.

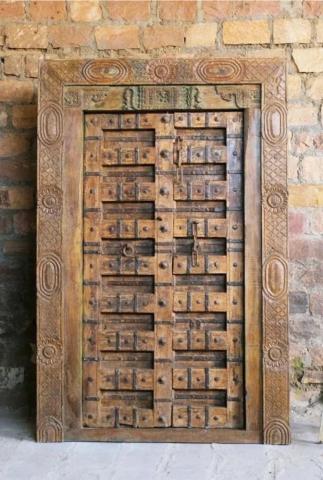

3. Surge in Demand for Interior Aesthetics

There has been a noticeable uptick in demand for biophilic and natural design trends in both commercial and residential interiors. Acoustic Wood Panels not only offer sound absorption benefits but also bring in the warmth and elegance of wood. This dual appeal has intensified pressure on raw wood supplies.

4. Competition from Other Industries

The construction, furniture, and packaging sectors also rely heavily on timber, creating fierce competition for the same raw material pool. Wooden Acoustic Panels, although niche, are being affected disproportionately due to their reliance on specific grades and finishes of wood.

Impacts on Manufacturers and Designers

The shortage of high-quality wood has compelled manufacturers to reassess their production strategies. Many are now faced with difficult decisions:

Switching to Alternative Materials: Some companies have explored non-wood substitutes or composites for panel production, but these often fall short in matching the acoustic performance or visual appeal of genuine Wooden Acoustic Panels.

Reevaluating Product Lines: With selective availability of raw wood, manufacturers are streamlining product offerings, often focusing on high-demand or customizable Wood Acoustic Paneling solutions.

Rising Prices: Limited supply inevitably means higher costs. This price inflation is passed on to designers, contractors, and end clients, reshaping budget allocations for acoustical treatments.

Strategies to Navigate the Raw Material Shortage

While the challenges are significant, the Acoustic Wood Panels industry is also showing remarkable resilience. Here’s how businesses and stakeholders are adapting:

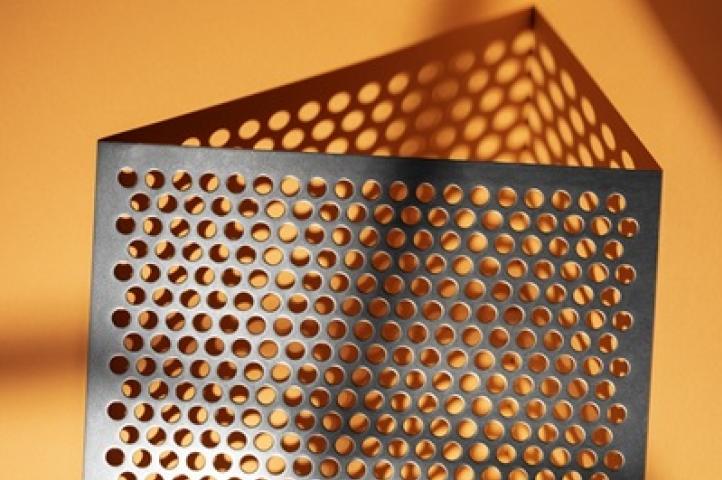

1. Embracing Engineered Wood Solutions

Engineered woods such as MDF, HDF, and plywood are increasingly being used as the base for Wood Acoustic Paneling, with real wood veneers providing the desired finish. These alternatives offer better material efficiency while maintaining a high-quality look and feel.

2. Optimizing Waste Management

Sustainable practices in the production of Wooden Acoustic Panels now include intelligent waste management systems—where off-cuts and trimmings are repurposed—thereby maximizing yield from limited raw materials.

3. Investing in Local Sourcing

Global dependence is being reduced as manufacturers invest in local or regional wood sources. While this may limit some design flexibility, it ensures a more stable and reliable supply of material for Acoustic Wood Panels.

4. Customization and Made-to-Order Models

Rather than mass-producing a wide variety of panels, more manufacturers are turning to a “made-to-order” model. This allows for better control over resource usage and minimizes the need to stockpile raw materials. It’s also giving rise to bespoke Wood Acoustic Paneling solutions that cater specifically to client requirements.

5. Innovation in Finishes and Treatments

With certain wood species harder to obtain, manufacturers are exploring advanced finishing techniques that replicate the appearance of exotic woods. Laminate veneers, 3D textures, and color treatments help retain the premium aesthetic of Wooden Acoustic Panels, even when using more readily available wood types.

Role of Polyester Panels Sustainability

Amid raw material constraints, sustainability has moved from being a nice-to-have to a business imperative. The most forward-thinking players in the Acoustic Wood Panels space are not just reacting to shortages—they are building resilient, environmentally responsible supply chains. This includes:

Sourcing FSC-certified timber

Transparent documentation of material origins

Offering eco-conscious acoustic solutions using recycled content

Wood Acoustic Paneling manufacturers who align with these values are not only meeting regulatory demands but also gaining favor with architects and designers committed to green building standards such as LEED and WELL.

What Lies Ahead?

Looking forward, the Wooden Acoustic Panels industry must continue to innovate to maintain growth amid material scarcity. Collaboration across the value chain—manufacturers, suppliers, architects, and clients—will be essential to develop smarter, more sustainable products.

Digital tools such as AI in inventory management, BIM for space planning, and data analytics for forecasting demand will also play a role in reducing waste and improving procurement strategies. Additionally, ongoing R&D into bio-based resins and composite materials could eventually open up alternatives that rival wood in acoustic performance and appearance.

Conclusion

The raw material shortage is undeniably reshaping the landscape of Acoustic Wood Panels. While the crisis presents immediate hurdles, it is also acting as a catalyst for innovation and sustainability. As manufacturers become more agile and designers more open to creative alternatives, the future of Wood Acoustic Paneling looks both responsible and resilient. By embracing change and working collaboratively, the industry can continue to deliver high-performance, visually stunning Wooden Acoustic Panels that meet the demands of modern design.