A Metal False Ceiling must meet strict fire safety standards. Architects and builders rely on proper codes. Compliance ensures occupant safety and legal approval. This article explains fire ratings and regulations related to Metal False Ceiling design. Proper knowledge leads to safer structures and better decisions.

Understanding Fire Ratings

Fire ratings define how long a material resists flame exposure. For any Metal False Ceiling, the ceiling must show non-combustible properties. Class A or Class 1 ratings are common requirements. These designations help code officials approve installations. The goal is to limit flame spread and heat transfer.

Why Do Fire Ratings Matter?

Fire can spread rapidly through unprotected building components. A Metal False Ceiling with appropriate fire resistance slows smoke and heat propagation. This delay gives occupants more time to evacuate. It also protects structural integrity during emergencies. Fire-rated ceilings also reduce insurance risks.

Relevant Building Codes

Building codes dictate minimum standards for a Metal False Ceiling. Government or local jurisdictions often refer to NFPA or local fire codes. Designers must reference codes when planning new construction or renovation involving Metal False Ceiling systems. Adhering to codes prevents legal liabilities and ensures safe practices.

Certification Process

Manufacturers must test Metal False Ceiling panels under ASTM or EN standards. Test results show fire resistance in minutes. Lab certifications must accompany each Metal False Ceiling product. Inspectors rely on this documentation before granting approvals. Products without this proof are typically rejected.

Material Choices and Compliance

Selecting appropriate materials is key for a compliant Metal False Ceiling. Certain metals perform better under heat. For example, aluminium false ceiling panels are non-combustible and lightwehttps://tranquilglobal.com/blog/tactile-design-rise-textured-polyester-acoustic-board-that-demand-attention/ight. They naturally resist flame and offer good performance under fire stress.

A standard metal ceiling may not meet codes unless certified. Panels made from untreated steel need fire-rated treatment. This applies equally to other metal types used in ceilings.

Specific Ceiling Types

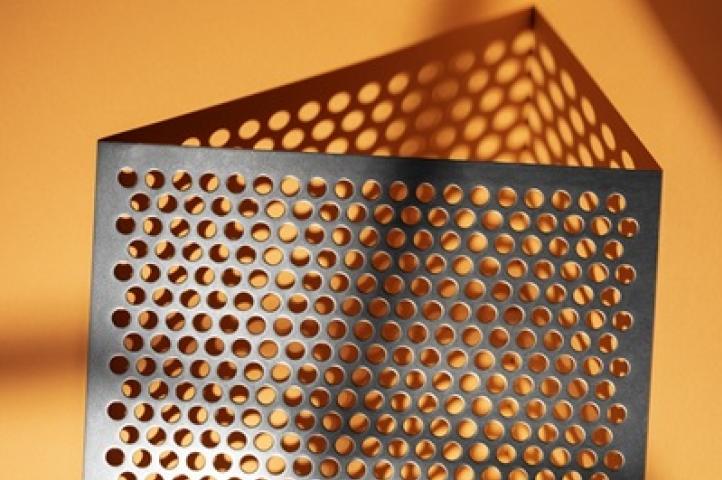

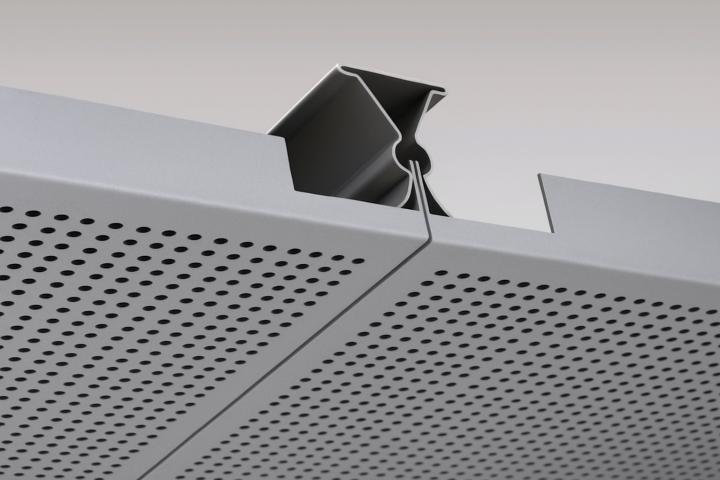

Perforated Metal Ceiling

A perforated metal ceiling offers acoustic control. However, it still needs fire compliance. Perforated panels must bear fire rating marks. They often require backing or insulation to reach fire code standards. Fire resistance must remain unaffected despite aesthetic perforations.

Metal Baffle Ceiling

A Metal baffle ceiling >

Installation Considerations

Installers must follow approved methods for a Metal False Ceiling. Use non-combustible hangers and clips. Maintain the required clearance between the ceiling and the structural slab, as specified by code. Never mix non-rated materials with certified panels.

Each fixture, duct penetration, and support must maintain the same fire rating. Any cutouts for lighting or air must be sealed using compliant materials. This ensures the Metal False Ceiling continues to meet fire safety expectations.

Maintaining Compliance Over Time

Ceilings age and buildings change. Periodic inspection ensures the Metal False Ceiling continues to meet standards. Replace damaged sections. Avoid retrofitting uncertified additions above existing fire-rated panels. Document every change and maintain updated records for review.

Ventilation and Access

Access panels should be fire-rated in a Metal False Ceiling system. Maintenance hatches must maintain full fire performance. Ventilation openings require fire dampers to match rating levels. This preserves ceiling integrity during fire events. Every component must meet the same standard.

Environmental Factors

Humidity or chemical exposure can affect the finish, but not the fire rating of a Metal False Ceiling. Corrosion-resistant coatings applied to aluminium false ceiling or metal ceiling sets maintain compliance. Avoid rusting fixtures or expired adhesives when servicing.

Documentation and Approval

Always keep test certificates and product data sheets for each Metal False Ceiling. Submit these to the code officials before installation. Keep digital or printed records onsite throughout the building’s life. Proper documentation speeds up inspection and reassures clients.

Emergency Response Planning

An approved Metal False Ceiling contributes to overall life safety design. Planners should map out evacuation routes, considering ceiling fire performance. Emergency lighting and sensors can integrate into the ceiling system if panels are rated accordingly.

Final Thoughts

Specifying a compliant Metal False Ceiling requires attention to fire rating and code requirements. Materials like aluminium false ceiling often perform well under stringent standards. Options such as perforated metal ceiling or Metal baffle ceiling can be used safely when properly certified.

Proper certification, installation, and maintenance ensure code compliance and occupant safety. With the right strategy, a Metal False Ceiling can deliver both aesthetic appeal and vital fire protection. Choose wisely, and ensure your project stands the test of safety and regulation. check out our website to explore more : https://www.tranquilglobal.com/index.html