Sound shapes the way we experience a space. Whether it's the calm hush in a wellness center, the focused silence in a corporate office, or the vibrant buzz in a classroom, acoustics define comfort, productivity, and usability. Architects, now more than ever, carry the responsibility to not just build aesthetically pleasing environments but also to enhance their acoustic performance. Among the various materials available today, PET polyester acoustic panels have emerged as one of the most preferred solutions. But before incorporating them into your next design, here’s what you absolutely must know.

Understanding the Material: More Than Just Fabric

At first glance, polyester fibre acoustic panels might appear simple—a felt-like material, lightweight, and easy to cut. But their engineered purpose goes far beyond that. Made primarily from recycled PET (polyethylene terephthalate), these panels are both environmentally responsible and acoustically efficient.

They are designed to absorb mid and high-frequency sound waves, significantly reducing noise, echoes, and reverberations. This makes them ideal for spaces where speech clarity and auditory comfort are essential—conference rooms, educational institutions, open-plan offices, restaurants, and healthcare environments.

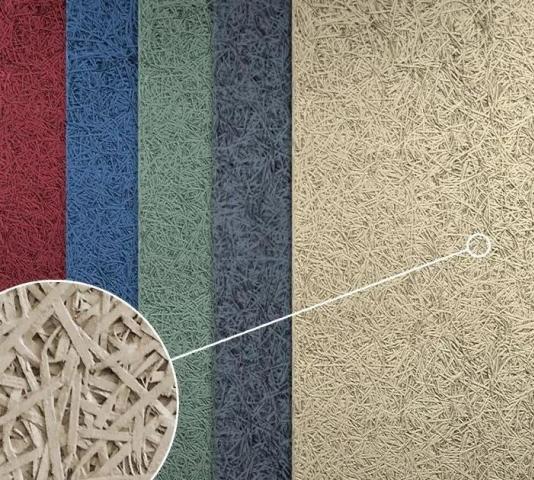

What distinguishes PET polyester acoustic panels from traditional options is not just performance but also versatility. They can be customized in terms of thickness, density, size, color, and even surface finish—be it grooved, carved, embossed, or printed.

What to Know Before Application

While the material offers high flexibility and performance, some practical considerations should be kept in mind before specifying polyester acoustic board:

1. Substrate Matters

Although panels are self-supporting, their placement surface affects their performance and longevity. Mounting on smooth, flat, and dust-free substrates ensures maximum adhesive grip and proper alignment. Avoid areas exposed to direct moisture unless you’re using specially treated panels.

2. Application Area Planning

Before installation, assess the space’s acoustic pain points—are there echoes? Does the space get too loud during peak hours? Are specific zones more problematic than others? Target those zones with the right panel configuration—wall coverings, baffles, or ceiling clouds.

3. Fire Ratings and Safety

A professional architect must always inquire about the fire safety certifications. Most quality polyester fibre acoustic panels are tested to meet Class B or Class A (ASTM E84 or EN13501) fire ratings. Always check these credentials, especially in high-occupancy public buildings.

Acoustic Performance You Can Count On

The core reason architects and designers opt for polyester acoustic board systems is because of their consistent sound-absorbing ability. Panels generally offer NRC (Noise Reduction Coefficient) ratings ranging from 0.75 to 0.95, depending on thickness and surface design.

For a space planner, this translates to:

Reduced sound reflections

Better speech intelligibility

A quieter, more focused ambiance

Additionally, polyester fibre acoustic panels do not contain formaldehyde or other harmful VOCs, ensuring indoor air quality isn't compromised. Their hypoallergenic, odorless, and mold-resistant nature also adds to their appeal, especially in healthcare and educational environments.

Design Possibilities That Go Beyond Expectations

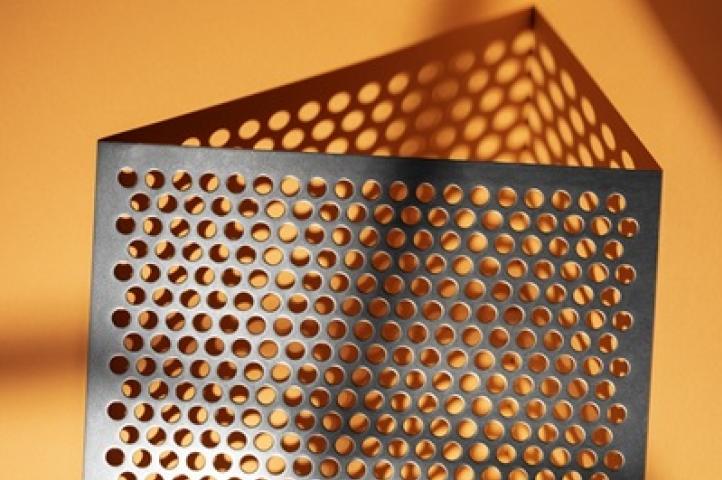

Gone are the days when acoustic materials were bulky, unattractive, and hidden behind drywall or perforated boards. Today, PET polyester acoustic panels double up as both acoustic and visual design elements.

Architects can play with:

Layering and depth: Combine flat panels with 3D carved ones for dynamic aesthetics.

Color schemes: Choose from a wide palette that aligns with the brand or environment theme.

Custom prints and shapes: Integrate wayfinding, branding, or graphic storytelling directly onto the panels.

Their lightweight nature allows for easy wall mounting, hanging baffles, or cloud ceiling formations. As a designer, this means fewer constraints and more creative freedom.

Connect with us to explore the range of finishes and printed acoustic panels suitable for your upcoming interior design projects.

Sustainability and Certifications

Environmental responsibility is no longer optional—it’s an architectural responsibility. These panels are generally manufactured using up to 60% post-consumer recycled PET, which means they contribute to green certifications.

They’re also 100% recyclable, making them a smart choice for firms conscious of life-cycle impacts.

Looking to integrate eco-conscious acoustic solutions into your design palette? Reach out to us for detailed product data sheets, test reports, or sustainable specification support.

Maintenance: An Often-Overlooked Advantage

Unlike many other acoustic materials, PET polyester acoustic panels require almost zero maintenance. Their dense fiber structure resists dust accumulation, and occasional vacuuming or a gentle wipe-down is usually sufficient.

This low-maintenance advantage makes them especially suited for high-traffic or hard-to-access areas like ceilings or tall wall claddings.

Budget-Friendly Without Compromise

Cost plays a crucial role in material selection. Fortunately, polyester acoustic board systems offer an excellent balance between affordability and performance. They eliminate the need for complicated sub-structures, surface finishes, or expensive mounting hardware.

Moreover, installation is quick, clean, and doesn’t typically require skilled labor—another hidden saving architects should factor in while budgeting.

The Final Word: Acoustic Elegance with Performance

PET polyester acoustic panels aren’t just an add-on—they’re a design decision. They give architects the power to transform spaces not only visually but also experientially. The next time you’re planning an office renovation, designing a school, or building a sound-sensitive retail space, give due importance to how the space will sound—and not just how it looks.

The right acoustic strategy makes your design more human, more functional, and ultimately more successful.