Mining has always been an

industry of scale – vast sites, heavy machinery, and operations spread across

rugged, and often remote locations. But with this scale comes complexity and

risk. Keeping track of such expansive environments involves not just a logistical

challenge, but also safety, efficiency, and operational continuity issues.

Technological change is

not new to the mining industry. Automation, digital tools, and connected

machinery have gradually reshaped how sites operate. But one area has lagged

behind: real-time, centralized monitoring of site activities and risks.

The Hidden Corners of Mines:

Mining’s Overlooked Risks

Every mining site has its

visible frontlines – the bustling haul roads, towering equipment, and control

rooms alive with data feeds. But beyond these visible zones lie the hidden

corners – isolated areas, blind spots, and stretches of terrain where oversight

fades and risk quietly builds.

The consequences of these

visibility gaps are far from theoretical. According to a report published by the

U.S. National Institute for Occupational Safety and Health (NIOSH), more than

40% of the most serious mining injuries entail “caught-in”

or “struck-by” incidents, mostly near powered haulage or machinery,

where line-of-sight is compromised.

The magnitude is extensive.

Open-pit mines stretch thousands of hectares, and underground sites descend

into areas where conventional monitoring struggles. Fragmented cameras and

occasional inspections often leave large sections unobserved.

Eliminating these gaps

requires more than just adding cameras; it demands integrated monitoring that

stitches together every corner of the site into a single, connected system of

awareness.

Beyond the Control Room:

How Smart Site Monitoring Solutions (SSMS) See Every Corner of the Mine

In mining, real-time

awareness shouldn’t end within the walls of the control room. But for many

sites, that’s exactly where it does. Beyond that, risks are overlooked, holdups

increase, and vigilance falters.

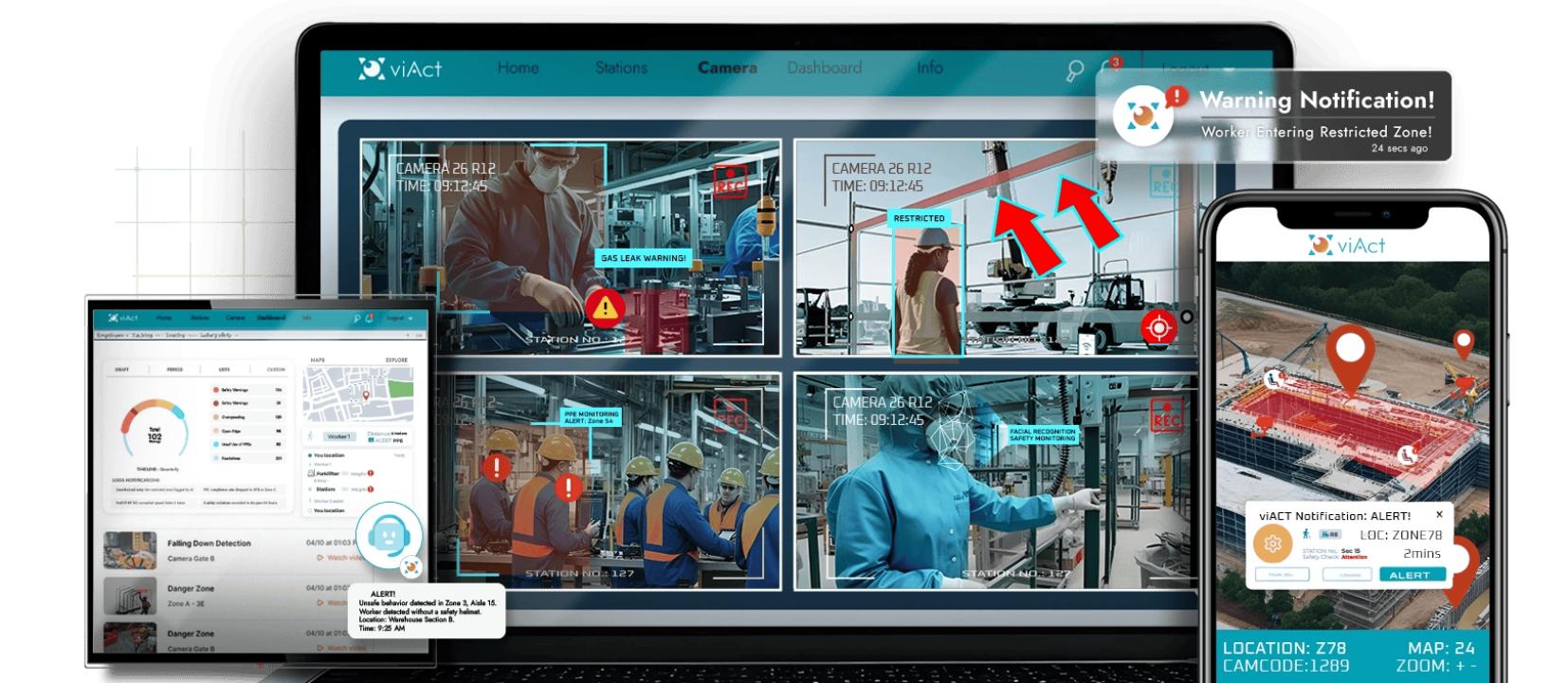

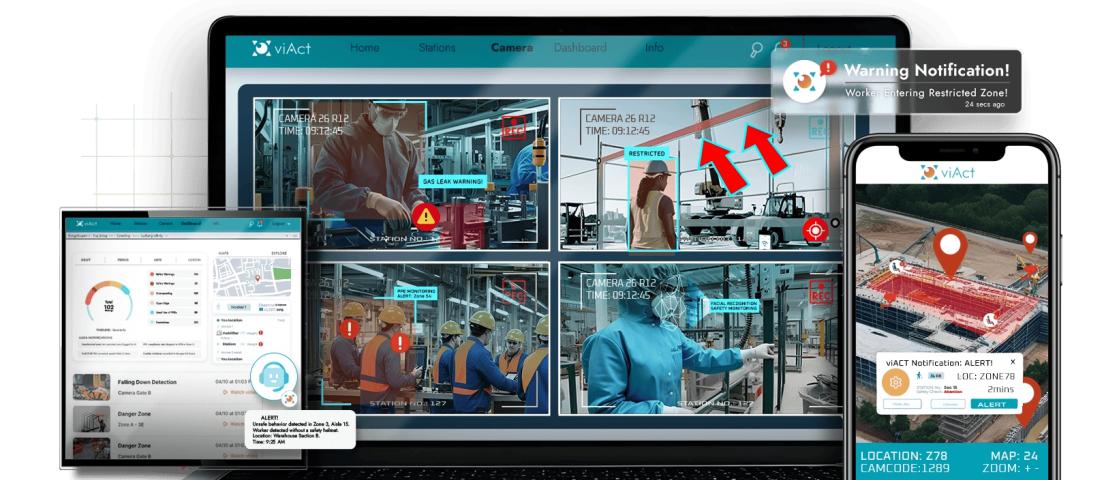

Here, SmartSite Monitoring Solutions (SSMS) steps in. Combining AI

video analytics, IoT sensors and devices, and edge devices, SSMS amplifies

visibility beyond traditional boundaries, helping create a real-time, connected

view of every corner of the mine. From haul roads to underground sections, the

entire site gets connected, visible, and easier to manage.

Smart Site Monitoring

Solutions (SSMS) turns fragmented data into actionable site-wide awareness. The

result? Operators detect hazards sooner, respond faster, and keep the entire

operation within view. From control rooms to the farthest corners, SSMS ensures

no part of the mine operates in the dark.

Anatomy of a Smart Site

Monitoring Solution (SSMS)

Site-wide awareness in

mining relies on more than just cameras or dashboards; it is the result of

multiple technologies working together. Smart Site Monitoring Solutions (SSMS)

combine these tools into a connected system, turning scattered site data into

real-time visibility.

Here’s how it all comes

together:

·

AI CCTV & Video Analytics: The

Eyes on the Ground

For a long time, cameras

have been used for site monitoring, but their function have evolved recently. These

cameras, powered with AI and video analytics, offer proactive safety

monitoring, identifying hazards in real-time.

Smart video analytics can

automatically identify workplace hazards, like slips, trips and falls,

musculoskeletal disorders, and unauthorized access. Across expansive mining

sites, these advanced video analytics systems serve as ever-present monitors,

enhancing traditional surveillance capabilities.

· IoT

Sensors & Devices: The Ears and Nerves of the Mine

IoT sensors and devices quietly

listen, sense, and transmit information that aligns operations with

environmental needs. Deployed across vehicles/ equipment, these smart IoT sensors

and devices continuously monitor vital signs, from air quality and machine

health to temperature, dust levels, and structural conditions.

By detecting the subtle

signals that cameras miss, like gas levels, vibration changes, or early signs

of equipment stress, IoT sensors help detect potential risks long before they

escalate.

· Edge

Device: The Brain Behind Real-Time Decisions

In mining, visibility

alone isn’t enough; making sense of data in real-time is what keeps operations

running safely and efficiently. This is where edge devices step in: processing data

locally, directly at the site, without delay.

Today, edge processing

extends beyond fixed infrastructure. Portable edge devices, like viMOV, allow

real-time data collection and analysis to happen anywhere, from haul roads to

underground sections.

By reducing dependency on

connectivity and enabling immediate alerts, edge devices ensure that critical

information stays close to the operation, where decisions are made, and where

response times matter most.

More Than Safety: The

Wider Impact of Real-Time Site Monitoring

Though safety remains the

primary advantage of Smart Site Monitoring Solutions (SSMS), its impact is

far-reaching. Real-time site monitoring also helps simplify workflows, minimize

downtime, and support regulatory compliance – all critical for keeping complex

sites running smoothly.

“Modern mining operations

generate enormous amounts of data, but without real-time visibility, that

information often stays trapped in silos,” says Gary Ng,

CEO of viAct.

“Bringing it together through integrated monitoring isn’t just about safety;

it’s about running more efficient, responsive operations.”

As monitoring tools

become more advanced, mining operations gain not only safer environments but

also greater control over day-to-day efficiency and long-term site performance.

Reimagining Mining Site

Awareness

A connected mine is no

longer a vision for the future; it is becoming the foundation of how modern

operations run. With Smart Site

Monitoring Solutions (SSMS), control rooms are no longer just passive hubs for

data collection, it becomes a proactive nerve center for the entire operation.

Combining data from real-time

insights, sensors, and local processing, Smart Site Monitoring Solutions (SSMS)

give operators the clarity to act and not just react. It bridges the gaps,

connects the site, and restructures how teams stay ahead of risks, keeping

operations running smoothly.

In an industry, like

mining, where visibility is the foundation of both safety and productivity, Smart

Site Monitoring Solutions (SSMS) is quietly reshaping how mining teams see,

manage, and protect their sites.