Finding a reliable source is one of the most crucial

things firms do when they need to purchase raw materials for creating items

like paints, plastics, cosmetics, or refractories. In..

IntroductionIn the pulsating world of industrial machinery, power must be transferred reliably, efficiently, and consistently. At the very core of this motion lies a component so fundamental that it's often..

Conveyor Systems are important tools used to move goods from one place to another within different sectors of Indian industry including; manufacturing, mining, warehousing, fast moving consumer goods (fmcg), logistics,..

SKC Industries LLP (SKC Salt) stands among the most trusted salt manufacturers in India, known for delivering premium-quality edible and industrial salt to domestic and international markets. Based in Gandhidham,..

SKC Industries LLP (SKC Salt) stands among the most trusted salt manufacturers in India, known for delivering premium-quality edible and industrial salt to domestic and international markets. Based in Gandhidham,..

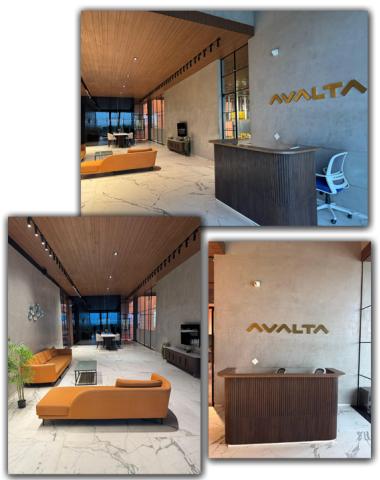

Welcome to Avalta Granito — Where Craftsmanship & Innovation MeetAt Avalta Granito, our legacy is built on the solid foundation of quality, design and global standards. Located in Morbi, Gujarat,..

Nowadays we have

adopted modernity so much that in many cases we cannot keep up with traditional

things. Therefore it is necessary to follow our customs properly to maintain

our..

Efficiency and safety are vital to the fitness of the modern construction industry. The construction industry often requires reliable lifting mechanisms to be used in lifting steel beams or moving..

Pratibha Refractory Minerals is a leading Talc Manufacturer and Talc Powder Supplier from India, offering the finest quality talc and soapstone products for industrial and cosmetic applications. With decades of..

In industries spanning cosmetics, ceramics, paint, rubber, and plastics, the demand for high-quality talc powder is ever growing. But with many players in the market, how do buyers pick a..

Having a dependable battery source matters. A trusted battery supplier in Sutherland Shire becomes a lifeline for people needing reliable and long-lasting batteries across different uses. Dedicated battery shops offer..

SKC Industries LLP (SKC Salt) stands among the most trusted salt manufacturers in India, known for delivering premium-quality edible and industrial salt to domestic and international markets. Based in Gandhidham,..

SKC Industries LLP (SKC Salt) stands among the most trusted salt manufacturers in India, known for delivering premium-quality edible and industrial salt to domestic and international markets. Based in Gandhidham,..

Talc powder is one of the most useful and important industrial minerals out there. Talc is a major element in many industries, including plastics, paints, ceramics, cosmetics, and pharmaceuticals. It..

IntroductionIn the mineral industry, Shyam Clay Industries stands out as a premier manufacturer and exporter of high-quality minerals. Based in Nadapa, Bhuj, Kutch (Gujarat), the company has more than two..

Looking for a reliable talc powder supplier in India for industrial use? Pratibha Refractory Minerals stands out for its commitment to quality, purity, and performance. Our high-grade talc powder is..

Planning an outdoor event—whether it’s a wedding, birthday bash, corporate gathering, or family reunion—requires careful consideration of space, comfort, and functionality. One of the most critical decisions is selecting the..

Are you searching for a reliable soapstone powder supplier in India? Soapstone, also called talc, is a versatile industrial mineral used in rubber, paper, paints, plastics, ceramics, and cosmetics. With..