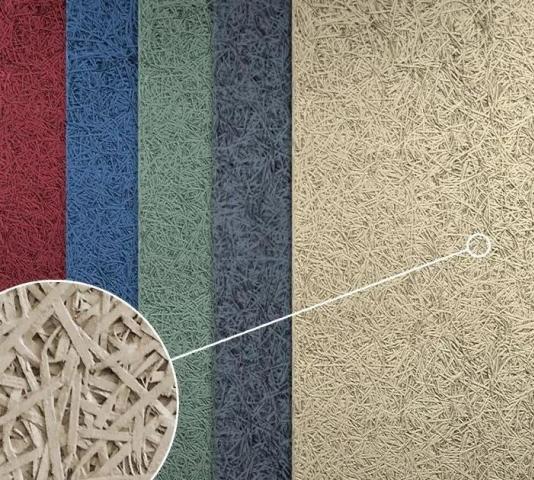

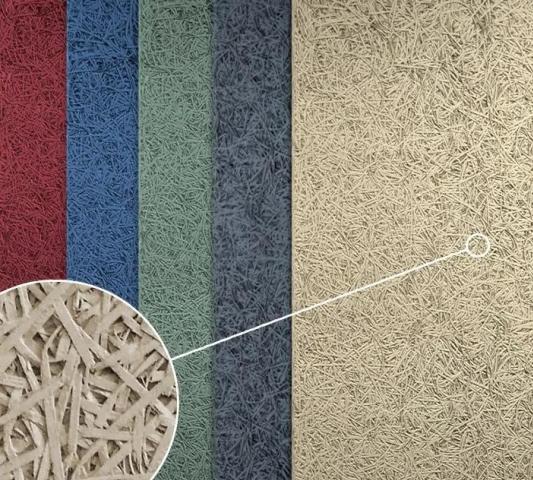

Acoustic design has become an integral part of modern architecture, not only for performance-driven spaces such as auditoriums, offices, or classrooms but also for homes and hospitality interiors. The need to blend aesthetics with functionality has pushed designers to adopt advanced acoustic materials that provide sound absorption without compromising on design appeal. One such widely preferred solution is the wood wool acoustic panel. Known for its natural look, eco-friendly composition, and superior performance, these panels are versatile enough to be used across ceilings and walls.

When it comes to installations, drywall surfaces are among the most common substrates where designers and contractors prefer mounting wood wool panels. This blog explores different approaches and techniques to install wood wool acoustic panels on drywall, with insights into their benefits, challenges, and applications.

Why Choose Wood Wool Acoustic Panels for Drywall Surfaces?

Drywall has become a popular construction choice due to its smooth finish, quick installation, and lightweight nature. However, by itself, drywall lacks acoustic insulation and may often amplify sound reflections. This makes it crucial to complement drywall with effective acoustic materials.

The wood wool acoustic panel offers multiple advantages:

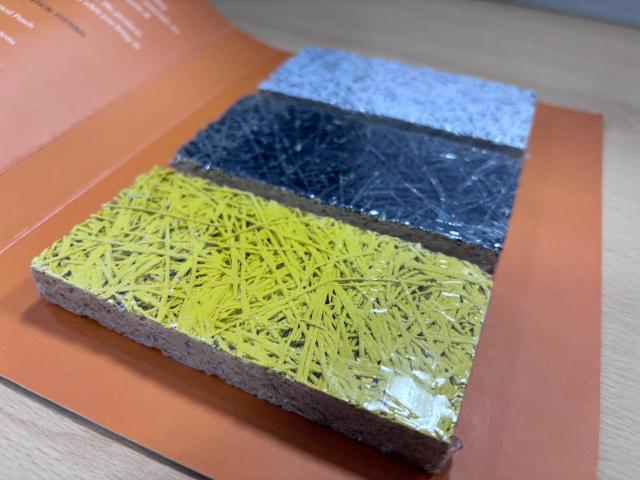

They are made from natural wood fibers bonded with cement, ensuring strength and durability.

Their porous structure effectively absorbs sound waves, reducing echoes and enhancing clarity.

They bring a rustic, textured aesthetic that blends well with both contemporary and traditional designs.

Easy to finish with paint or custom color coatings, they remain flexible for design requirements.

Given these qualities, the pairing of drywall and wood wool panels creates an efficient and visually pleasing acoustic solution.

If you are exploring reliable acoustic solutions for your projects, contact us today and we’ll guide you to the perfect product-fit.

Method 1: Direct Adhesive Fixing for Clean Finish

One of the simplest methods to fix wood wool acoustic panels on drywall surfaces is by using high-strength adhesives. This approach ensures a smooth, seamless finish, especially when the panels are meant to serve both acoustic and decorative purposes.

Surface Preparation: The drywall should be clean, dust-free, and leveled to allow uniform adhesion.

Application of Adhesive: A layer of recommended construction adhesive or polymer-based glue is applied at the back of the wood wool acoustic panel.

Fixing & Alignment: The panels are then pressed against the drywall with firm pressure, ensuring proper alignment and edge-to-edge fit.

This method works best for smaller installations or spaces where mechanical drilling is not desired. However, contractors must ensure that the adhesive used is strong enough to support the panel’s weight and acoustic function.

Looking for guidance on choosing the right installation method for your project? Contact us and our experts will assist you with technical details and product support.

Method 2: Screw Fixing with Mechanical Anchors

For larger installations or heavy-duty requirements, adhesive fixing alone may not be sufficient. This is where screw fixing with mechanical anchors becomes essential.

Marking & Drilling: Holes are pre-marked on the drywall and drilled to hold screws with plastic or metal anchors.

Panel Positioning: The wood wool panels are placed carefully, and screws are tightened through them into the anchors, ensuring they stay firm.

Finishing Touch: The screw heads can either remain exposed for an industrial look or be concealed with matching fillers.

This technique provides long-term stability, especially for high-traffic spaces such as schools, offices, or auditoriums where durability is crucial. Screw fixing also ensures the panels can be removed and reinstalled if needed.

Method 3: Wooden Frame or Batten System for Acoustic Enhancement

A highly recommended method for maximizing the acoustic performance of wood wool acoustic panels is fixing them on a wooden batten framework.

Framework Installation: Wooden battens are installed on the drywall surface with a grid or horizontal pattern.

Panel Placement: The wood wool panels are then mounted onto this frame, either by adhesive or screws.

Acoustic Cavity Advantage: The cavity created between the drywall and panels enhances sound absorption by trapping sound waves.

This method is not only practical but also enhances the NRC (Noise Reduction Coefficient) value of the installation. It works particularly well for studios, theaters, and performance spaces where superior acoustic treatment is a priority.

Need expert advice on choosing between batten or direct fixing methods? Reach out to us for consultation and project-specific recommendations.

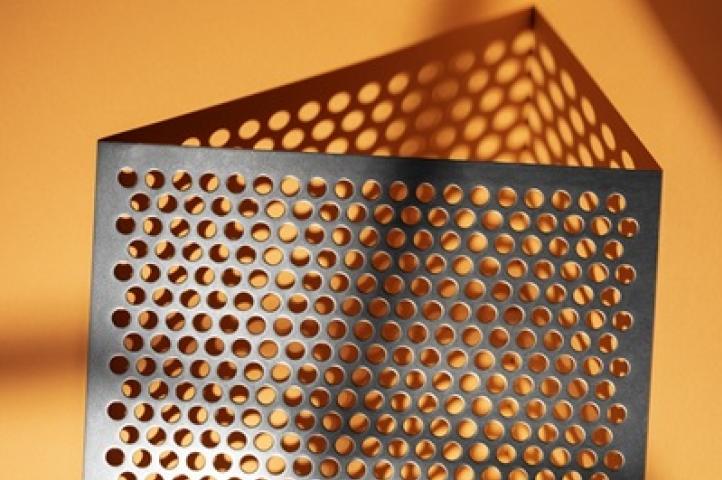

Method 4: Metal Channel System for Long-Term Durability

In spaces where extra durability and precision are required, a metal channel system can be used to mount wood wool acoustic panels.

Channel Fixing: Lightweight metal channels are anchored to the drywall.

Panel Integration: The wood wool acoustic panel is then fixed onto these channels with screws, creating a robust and lasting setup.

Design Flexibility: This method allows for modular arrangements and easy replacements in case of maintenance.

Though slightly more complex, this method guarantees stability and is well-suited for commercial projects.

Choosing the Right Fixing Method

The choice between adhesive fixing, screw fixing, wooden battens, or metal channels depends on several factors:

The type of project (residential, commercial, institutional).

The acoustic requirements (basic echo control vs. high-performance soundproofing).

Aesthetic preferences (exposed vs. concealed fixing).

Budget and time constraints.

By evaluating these parameters, designers and contractors can ensure the most suitable fixing method for wood wool acoustic panels on drywall surfaces.

Maintenance & Longevity of Installed Panels

Once installed, the performance and life of wood wool panels depend on proper maintenance. While these panels are robust, occasional dusting and careful cleaning will help maintain their visual appeal. Repainting can also be done if design updates are required. When correctly fixed, they can last for decades, continuing to serve as both effective acoustic materials and design elements.

Final Thoughts

The versatility of the wood wool acoustic panel lies not only in its acoustic efficiency but also in the flexibility of its installation methods. Whether you opt for adhesive fixing for a quick solution, screw fixing for durability, or advanced frameworks for enhanced performance, the outcome is a reliable blend of sound control and design appeal.

If you have a project that demands aesthetic strength with reliable acoustic control, contact us and our specialists will guide you through product choices and fixing solutions tailored for your requirements.https://www.tranquilglobal.com/contact-us.html