Introduction

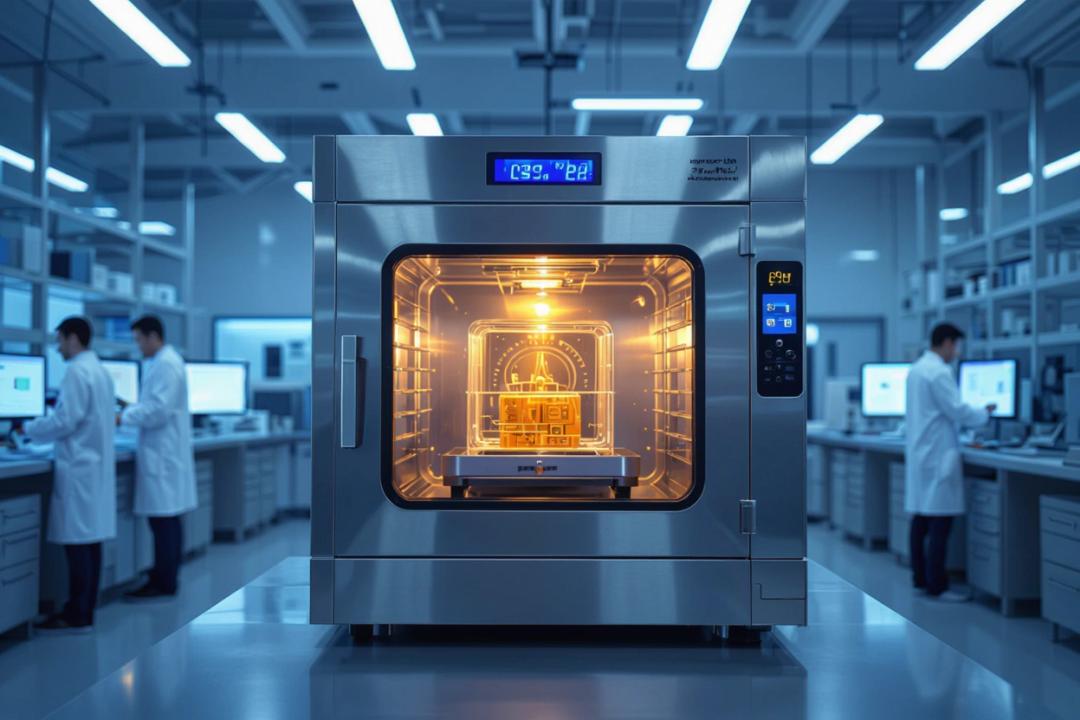

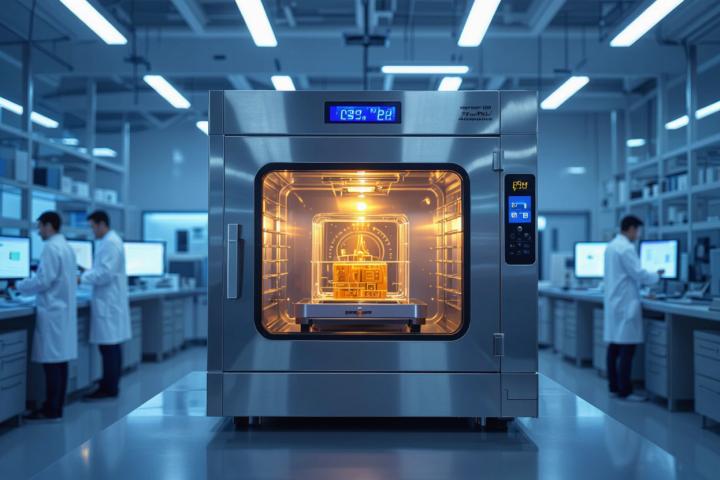

The demand for precision, speed, and efficiency in manufacturing is higher than ever. One area where automation is making a significant impact is in injection moulding processes. Traditionally labour-intensive, moulding is now being transformed with the integration of injection moulding robots. These advanced systems streamline production, reduce errors, and ensure consistent quality, making them indispensable for modern industries.

What Are Injection Moulding Robots?

Injection moulding robots are specialised automation systems designed to work alongside injection moulding machines. Their primary functions include:

- Removing moulded parts safely and quickly.

- Performing pick and place operations.

- Managing sprue removal and waste handling.

- Assisting in secondary operations like stacking, packaging, or assembly.

Depending on the application, manufacturers can choose between sprue pickers, top-entry robots, or side-entry robots.

Types of Injection Moulding Robots

- Sprue Picker Robots: Simple, compact robots designed to remove sprues from moulding machines.

- Top Entry Robots: Ideal for high-speed and high-precision operations, often used in packaging and thin-wall moulding.

- Side Entry Robots: Designed for applications requiring faster cycle times and horizontal part removal.

- 3-Axis and 6-Axis Robots: Provide flexibility for complex movements, secondary operations, and advanced automation needs.

Benefits of Injection Moulding Robots

- Increased Productivity – Faster cycle times with uninterrupted operation.

- Consistent Quality – Reduced human error ensures uniform moulded products.

- Enhanced Safety – Minimises risks by reducing manual handling.

- Cost Savings – Long-term labour and material savings outweigh initial investment.

- Flexibility – Robots can be reprogrammed to handle different moulding tasks.

Applications of Injection Moulding Robots

- Automotive Industry – Precision moulding of components like dashboards, trims, and clips.

- Consumer Goods – Production of toys, containers, and plastic items.

- Electronics – Handling delicate moulded components with accuracy.

- Medical Devices – Sterile and precise moulding for syringes, vials, and equipment parts.

- Packaging – High-speed moulding and stacking of food and beverage containers.

Challenges in Adopting Injection Moulding Robots

- High Initial Costs – Investment may seem steep for small manufacturers.

- Training Needs – The Workforce must be trained to operate and maintain robotic systems.

- Integration with Legacy Systems – Adapting robots to older moulding machines can be complex.

Despite these challenges, the ROI (Return on Investment) is strong due to reduced labor, higher efficiency, and fewer defects.

The Future of Injection Moulding Automation

The integration of AI, IoT, and smart sensors is driving the future of moulding automation. Future trends include:

- Predictive Maintenance – Reducing downtime with AI-driven fault detection.

- Collaborative Robots (Cobots) – Working safely alongside human operators.

- Energy-Efficient Designs – Lowering energy consumption while boosting performance.

Delta Stark Engineering: Your Partner in Injection Moulding Automation

At Delta Stark Engineering, we provide customised injection moulding robots designed to enhance your production efficiency and quality.

Our offerings include:

- Sprue Pickers, Top-Entry & Side-Entry Robots

- Precision 3-axis and 6-axis robots

- Automation solutions tailored to industry needs

- End-to-end support, including installation, training, and maintenance