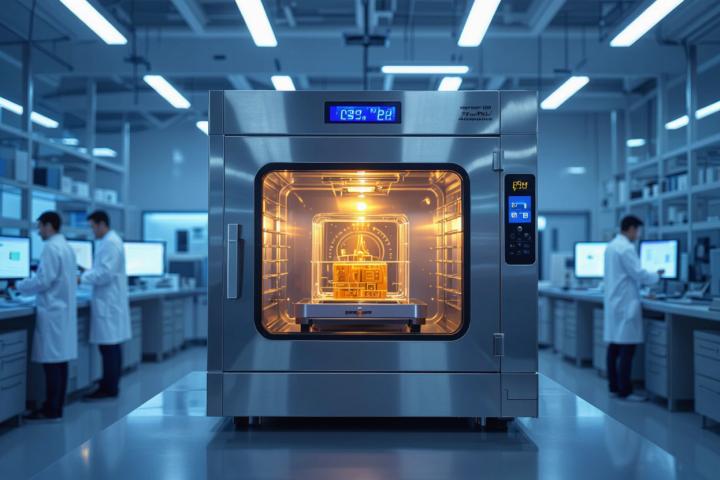

Injection Moulding Robots: Transforming Modern Manufacturing

Introduction

Injection moulding robots are reshaping the way plastic components are produced across industries. By combining precision engineering with automation, these robots help manufacturers achieve higher efficiency, consistent quality, and safer production environments. As demand for accuracy and scalability grows, injection moulding robots have become an essential part of modern manufacturing setups.

What Are Injection Moulding Robots?

Injection moulding robots are automated robotic systems integrated with injection moulding machines. Their primary role is to handle tasks such as part removal, insert placement, assembly, inspection, and packaging. These robots operate with high repeatability and accuracy, reducing dependence on manual labor.

Types of Injection Moulding Robots

1. Cartesian (Linear) Robots

These are the most commonly used robots in injection moulding. They move along X, Y, and Z axes and are ideal for fast and precise part removal.

2. SCARA Robots

SCARA robots are compact and suitable for high-speed assembly and pick-and-place operations in injection moulding cells.

3. Articulated Robots

With multiple rotating joints, articulated robots offer flexibility and are used for complex tasks like multi-angle assembly, trimming, or secondary processing.

4. Collaborative Robots (Cobots)

Cobots are designed to work safely alongside humans. They are increasingly used in small to medium-scale injection moulding operations.

Key Functions of Injection Moulding Robots

-

Automatic part extraction from moulds

-

Insert loading before moulding

-

In-mould labelling (IML)

-

Quality inspection and sorting

-

Packaging and palletizing

-

Secondary operations such as drilling or trimming

Benefits of Using Injection Moulding Robots

Improved Productivity

Robots operate continuously with consistent cycle times, increasing overall output.

Enhanced Product Quality

Automation ensures uniform handling, reducing defects caused by human error.

Increased Workplace Safety

Robots handle hot, sharp, or heavy moulded parts, minimizing worker exposure to hazards.

Cost Efficiency

Although initial investment is higher, long-term savings come from reduced labor costs and lower rejection rates.

Process Consistency

Robotic systems deliver repeatable performance, essential for high-volume production.

Industries Using Injection Moulding Robots

-

Automotive components

-

Consumer electronics

-

Medical devices

-

Packaging and containers

-

Electrical and industrial equipment

Future Trends in Injection Moulding Robotics

Injection moulding robots are evolving with Industry 4.0 technologies. Integration with sensors, AI-based vision systems, and data analytics allows real-time monitoring and predictive maintenance. Smart robots will play a crucial role in achieving fully automated and connected manufacturing facilities.

Conclusion

Injection moulding robots are no longer optional in competitive manufacturing environments. They provide speed, precision, safety, and scalability, helping industries meet growing market demands. As automation technology advances, injection moulding robots will continue to drive innovation and efficiency in plastic manufacturing.