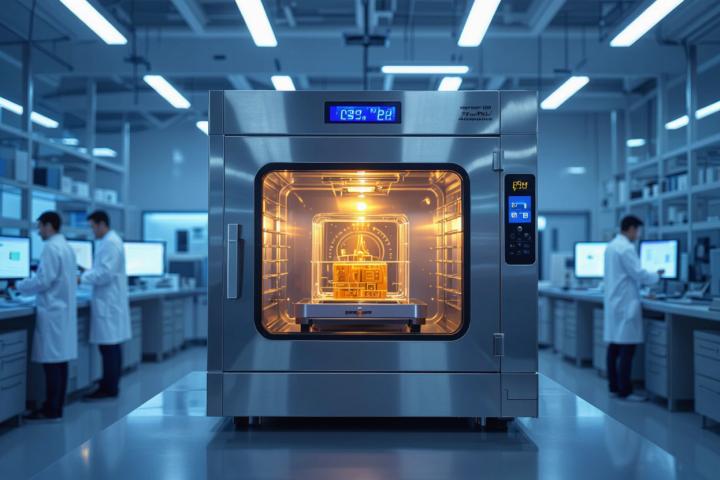

In the rapidly evolving world of plastic manufacturing, robots for injection moulding machines are becoming indispensable. These robotic systems automate repetitive and precise tasks, such as part removal, insert placement, stacking, and quality inspection, helping manufacturers achieve efficiency and consistency like never before.

Automation in injection moulding not only accelerates production cycles but also minimizes human error, reduces waste, and enhances workplace safety. Companies producing automotive components, consumer goods, and electronic parts benefit greatly from integrating robots into their operations.

Modern robots for injection moulding are equipped with intelligent controls, motion sensors, and advanced programming options. This enables manufacturers to handle complex moulding tasks, optimize production flow, and maintain consistent quality across batches. With predictive maintenance and real-time monitoring, these robots reduce downtime, lower operational costs, and improve overall productivity.

Investing in industrial robotic solutions for injection moulding ensures a competitive edge in manufacturing, helping businesses stay ahead in a fast-paced industry. Whether you are looking for side-entry robots, top-entry robots, or full automation systems, robotic integration delivers measurable results in speed, precision, and efficiency.

Conclusion:

As the demand for high-quality plastic components rises, integrating robots into injection moulding machines is no longer optional—it’s essential. By adopting robotic automation, manufacturers can achieve better efficiency, improved product quality, and significant cost savings, ultimately driving growth and success in their industry.