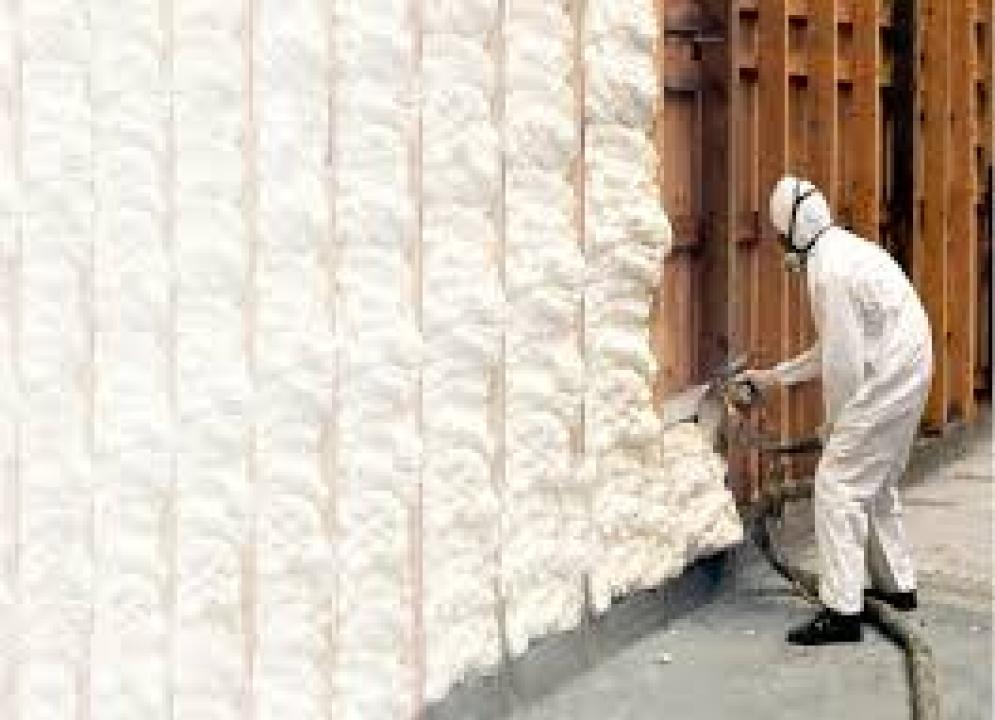

Of all the methods to hush a noisy world, few are as visually dramatic and technically effective as acoustic spray. This isn't your typical insulation; it’s a textural, seamless sound-absorbing blanket applied directly to your ceilings and walls. But with its rising popularity in everything from bustling restaurants to echoey gymnasiums, how do you decipher its capabilities?

Understanding an acoustic spray specification sheet is the key to knowing if this material is the right voice for your silence. Let's pull back the curtain and translate the key performance metrics from technical jargon into practical understanding.

The Core Mission: Stopping Sound from Bouncing

Before we dive into the numbers, it's crucial to grasp what acoustic spray is designed to do. Its primary job is sound absorption, not soundproofing.

Sound Absorption: This is about improving the acoustics within a room. It reduces echo, reverberation, and background noise by converting sound energy into minute amounts of heat as sound waves travel through its porous, open-cell structure. Think of a busy café where you can actually hear the person across from you.

Soundproofing: This is about preventing sound from travelling between spaces, like stopping your movie from bothering your neighbours. This requires mass and density (like extra drywall or mass-loaded vinyl).

Acoustic spray is an absorber. Its specification sheet is a report card on how well it performs that specific task.

Decoding the Key Performance Metrics

The key performance metrics are as follows:

1. Noise Reduction Coefficient (NRC): The Overall Absorption Score

What it is: The NRC is the single most important number on the sheet for most applications. It’s a simplified average that represents the material's ability to absorb sound across a range of mid-frequencies (generally 250Hz to 2,000Hz), the frequencies of human speech and typical office clatter.

How to read it?

The NRC is measured on a scale of 0.0 to 1.0 (though some highly effective products can exceed 1.0).

NRC 0.0: A perfect reflector. Think of a pane of glass; 100% of the sound hitting it bounces back into the room.

NRC 1.0: A perfect absorber. 100% of the sound hitting it is absorbed and does not bounce back.

NRC 0.75: This means the material absorbs 75% and reflects 25% of the sound that hits it.

What it means for you?

For general office spaces, classrooms, and restaurants, look for an NRC of 0.75 or higher. This indicates strong, all-around performance for taming conversational noise and general reverberation. A lower NRC might be acceptable for specific industrial applications, but is rarely suitable for occupied spaces.

2. Sound Absorption Average (SAA): The Modern Successor

What it is: The SAA is a more refined and comprehensive version of the NRC. It takes the average absorption across a wider frequency range (12 one-third octave bands from 200Hz to 2,500Hz). While NRC is still widely used, SAA is its official successor according to ASTM standards.

How to read it: The scale is the same: 0.0 to 1.0+.

The interpretation is identical to NRC. A higher SAA means better overall absorption.

What it means for you: Don't be alarmed if you see both NRC and SAA on a sheet; they are cousins. Often, the values are very similar. If you only see one, prioritise the SAA as it's the more modern metric. When comparing products, ensure you are comparing NRC to NRC or SAA to SAA.

3. Attenuation: The "Sound Masking" Bonus

This is where acoustic spray offers a hidden superpower that panels often lack.

What it is: Attenuation refers to the reduction of sound as it travels through a material. While acoustic spray isn't a true soundproofer, its thick, textured, and often fibrous/foamy structure does an excellent job of diffusing and scattering sound waves that travel laterally across a surface.

How to read it: This is often demonstrated rather than given a single number. Imagine two employees in an open office. Without treatment, a conversation can easily travel along a smooth, hard ceiling to someone dozens of feet away. With an acoustic spray applied, that path is broken up. The sound loses energy as it tries to navigate the uneven terrain of the spray.

What it means for you: This is critical for open-plan offices and large, open spaces. It doesn't just make the whole room quieter (absorption), it helps prevent clear conversations from intruding on adjacent workstations, enhancing speech privacy.

4. Flame Response & Smoke Developed: The Safety Guardians

You can't talk about performance without discussing safety, especially for a material applied over large surface areas.

What it is: These metrics describe how the material reacts to fire. In North America, this is typically measured by ASTM E84, the "Surface Burning Characteristics of Building Materials" test, also known as the "Steiner Tunnel" test.

Flame Spread Index (FSI): Measures how quickly flames travel across the material's surface.

Class A (FSI 0-25): Excellent resistance.

Class B (FSI 26-75): Good resistance.

Class C (FSI 76-200): Moderate resistance.

Smoke Developed Index (SDI): Measures the density of smoke produced. A value of 0-450 is reported, but most building codes require an SDI of 450 or less.

What it means for you: For virtually all commercial and residential applications, you should insist on a Class A Fire Rating (FSI 0-25). This is non-negotiable for code compliance and occupant safety.

5. Density & Thickness: The Physical Backbone

What they are: These are the physical properties that directly influence the acoustic performance.

Density: Measured in pounds per cubic foot (pcf or lb/ft³). A higher density often correlates with better low-frequency absorption, as it provides more resistance for sound waves to work against.

Thickness: Measured in inches (in). Thickness is a primary driver of performance, especially for low frequencies. Bass notes have long sound waves that require a thicker material to be effectively trapped and absorbed.

What it means for you: The NRC and SAA ratings are always given for a specific installed thickness. A spray applied at a 1-inch depth will have a significantly lower NRC than the same product applied at 1.5 inches. Always check the tested thickness against your project's design specifications.

The Intangible Advantage: Aesthetics and Seamlessness

While not a "metric" on a spec sheet, the aesthetic value of acoustic spray is a huge part of its performance. It creates a monolithic, visually quiet ceiling that eliminates the "checkerboard" look of individual panels. This seamless application contributes to its excellent attenuation properties and allows for unlimited design flexibility, including the integration of lighting and other fixtures without breaking the acoustic plane.

The Final Verdict

An acoustic spray specification sheet is not just a list of numbers; it's a story of how a material will behave in your space. Look for the powerful trio: a high NRC/SAA (≥0.75) for killing echo, a Class A Fire Rating for safety, and an understanding of how its thickness and attenuation will serve your specific spatial needs. By understanding these key metrics, you can move beyond the appealing texture and make an informed decision to turn your cacophonous challenge into a sanctuary of sound.