In the evolving world of architecture, construction, and interior design, the demand for innovative acoustic solutions is at an all-time high. As urbanization increases and spaces become more compact, the need to control noise—whether in commercial buildings, residential homes, studios, or industrial setups—has become crucial. Among the many products available for soundproofing, Mass Loaded Vinyl has emerged as a frontrunner, offering a blend of flexibility, effectiveness, and ease of use. Let’s dive into how this remarkable material is changing the way we approach sound management.

Understanding Mass Loaded Vinyl

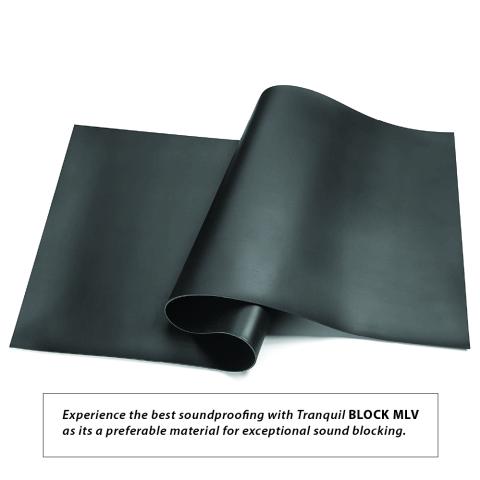

Mass Loaded Vinyl is a viscoelastic material that is loaded with high-mass elements like barium sulfate or calcium carbonate to add weight and density. The primary goal is to block or dampen sound waves by adding mass without increasing the thickness excessively. Originally developed in the 1960s, Mass Loaded Vinyl (commonly referred to as MLV) was created to provide an alternative to lead sheets for noise control—offering similar performance with less toxicity and greater flexibility.

What makes Mass Loaded Vinyl truly innovative is its unique composition. Despite its thin profile (usually around 1/8 to 1/4 inch thick), it has an exceptional ability to block airborne sound transmission. This property has made it an indispensable material in modern acoustic engineering.

Why MLV Soundproofing is a Game-Changer

MLV Soundproofing works primarily by increasing the mass of walls, floors, ceilings, or ducts, thereby reducing sound transmission through them. The principle is simple: the heavier and denser a material, the harder it is for sound to pass through. MLV Soundproofing adds this essential mass without taking up significant space, which is ideal for areas where thickness or aesthetics are a concern.

Some of the key advantages of MLV Soundproofing include:

Versatility: It can be installed in walls, ceilings, floors, and even around ductwork or pipes.

Flexibility: Unlike rigid soundproofing materials, MLV is pliable and can be cut and shaped to fit around curves or corners.

Efficiency: It offers high Sound Transmission Class (STC) ratings, often improving the STC of standard drywall assemblies by 6-10 points or more.

Ease of Installation: It can be applied with nails, screws, adhesives, or even Velcro, depending on the surface and application.

Whether you're renovating a home studio, building a high-performance office space, or soundproofing a mechanical room, MLV Soundproofing delivers results without the bulk of traditional materials.

Applications Across Industries

The versatility of Mass Loaded Vinyl makes it suitable for a wide range of applications across sectors:

1. Residential

Homeowners often face issues like noisy neighbors, traffic sounds, or home theater disturbances. Installing Mass Loaded Vinyl Sound Barrier behind drywall or beneath flooring significantly improves the peace and quiet of living spaces.

2. Commercial

In commercial buildings, especially offices or coworking spaces, acoustic privacy is essential. MLV Sound Barrier systems help create quieter, more productive environments by reducing sound bleed between rooms or floors.

3. Industrial

Industrial environments can be quite noisy, with machinery generating high levels of sound. Here, Mass Loaded Vinyl is used to line enclosures, walls, or machine housings to bring noise within safe levels and improve occupational safety.

4. Hospitality and Healthcare

Hospitals, clinics, and hotels rely on quietness for comfort and healing. Mass Loaded Vinyl Sound Barrier materials are often used in walls, ceilings, and mechanical rooms to ensure restful environments.

5. Automotive and Marine

Even vehicles benefit from MLV Soundproofing. From luxury cars to yachts, MLV is installed under carpets or inside door panels to reduce road and engine noise, enhancing comfort and user experience.

The Science Behind the Silence

At a molecular level, Mass Loaded Vinyl absorbs and blocks sound by resisting the movement of sound waves. When airborne sound hits an MLV sheet, its mass prevents the sound from transferring through, while its flexible properties help dissipate vibrational energy. This dual capability of blocking and damping makes MLV uniquely effective compared to rigid barriers.

The sound-blocking capabilities of MLV Sound Barrier are often quantified using STC ratings. An STC rating of 27-30 is common for standalone MLV sheets. However, when combined with drywall, insulation, or resilient channels, assemblies can reach STC ratings of 50 or more—sufficient to block loud speech and most environmental noise.

Installation Tips and Considerations

While Mass Loaded Vinyl is generally straightforward to install, there are a few best practices to ensure optimal performance:

Seal All Gaps: Sound can leak through even the smallest of cracks. Use acoustical sealant around edges and seams.

Overlap and Stagger: When laying multiple sheets, overlap the seams or stagger them to prevent direct sound paths.

Combine with Other Materials: Use Mass Loaded Vinyl in conjunction with insulation or resilient clips for superior performance.

Avoid Compression: Compressing MLV can reduce its effectiveness. Allow it to hang freely where possible.

Sustainability and Safety

Modern Mass Loaded Vinyl products are made with non-toxic, eco-friendly materials, offering a safer alternative to traditional lead-based soundproofing. Many manufacturers now offer low-VOC or recyclable MLV products that meet green building standards, making it an attractive option for LEED-certified projects or sustainability-focused developments.

The Future of Soundproofing

As buildings become more acoustically demanding and occupants seek quieter environments, Mass Loaded Vinyl is poised to remain a staple of acoustic design. Its flexible nature, combined with impressive performance and adaptability, makes it a favorite among architects, interior designers, and acoustic consultants alike.

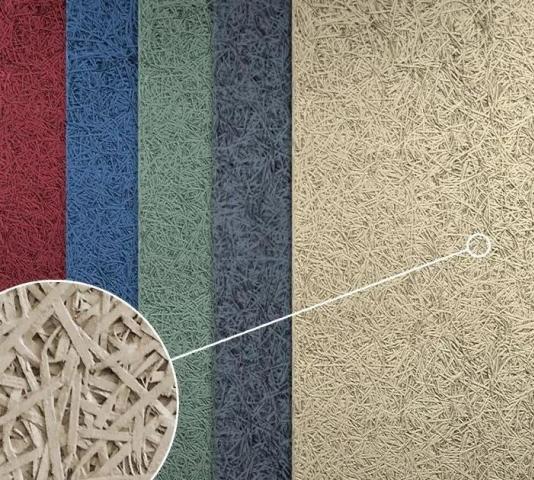

With advancements in material science, we may soon see even lighter and more effective iterations of MLV Soundproofing. There’s ongoing research into hybrid composites that incorporate Mass Loaded Vinyl with natural fibers or advanced polymers to further reduce weight while maintaining sound isolation.

Conclusion

In a world where silence is becoming a luxury, Mass Loaded Vinyl stands out as a practical, high-performing, and adaptable solution. Whether you're seeking to create a quiet home sanctuary, a professional-grade recording studio, or a peaceful office environment, MLV Soundproofing offers the performance you need without the complexity of conventional systems.

The next time you’re planning a space where sound control matters, don’t overlook the power of a Mass Loaded Vinyl Sound Barrier. This quiet giant might just be the most important layer in your design.