In the ever-evolving world of industrial design, the pursuit of functionality has never meant sacrificing form—or vice versa. As workspaces, factories, and open-concept commercial hubs continue to expand and redefine themselves, a quiet revolution is underway. One solution is making its way into the hearts of architects, acoustic consultants, and industrial designers alike: Acoustic Spray.

Once viewed merely as a soundproofing afterthought, Acoustic Spray has grown into a design-forward, performance-driven solution that blends seamlessly into contemporary industrial spaces. But why is it gaining so much popularity now? Let's dive into the reasons this material is making waves in industrial design.

Industrial Design Needs are Evolving

Industrial design isn't what it used to be. Gone are the days of cold, cavernous spaces filled with loud machinery and zero thought given to occupant comfort. Today’s industrial environments aim to be collaborative, safe, and acoustically balanced, while still maintaining high efficiency.

Modern industries—from automobile manufacturing to tech-based logistics—are increasingly recognizing that noise pollution affects not just communication and focus, but also safety and employee well-being. Enter Acoustic Spray: a versatile product designed to tackle reverberation and echo issues while preserving the raw, utilitarian aesthetics of industrial spaces.

What Is Acoustic Spray, Anyway?

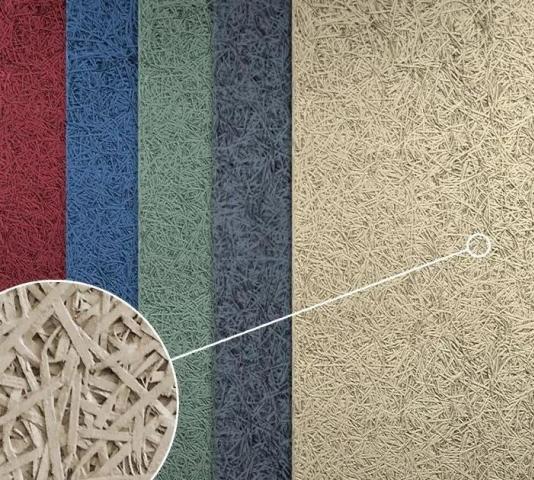

At its core, Acoustic Spray is a sound-absorbing treatment applied directly to surfaces like ceilings, metal decks, and concrete. It’s a mix of lightweight fibers, binders, and additives that form a seamless layer of insulation to absorb sound energy.

Unlike traditional panels or tiles, Acoustic Spray adheres directly to the architectural features of a space. This makes it an excellent solution for preserving the original design intent—especially in exposed structural environments where ducts, beams, and pipes are left visible on purpose.

Aesthetics Elements Meets Performance

Let’s be honest—no one wants to install ugly soundproofing in a beautifully designed space. One of the strongest appeals of Acoustic Spray is that it doesn’t intrude upon the aesthetic integrity of a project. Available in various textures and custom colors, it can either blend in subtly with a ceiling or be used to create a striking visual statement.

Designers appreciate that Acoustic Spray offers creative freedom while meeting acoustic performance benchmarks. It molds around beams, slopes, and contours—making it ideal for retrofit and new construction projects alike.

Efficiency in Application

Time is money, especially in industrial construction. Traditional acoustic solutions often require frames, mounts, and extensive labor. In contrast, Acoustic Spray is quick to apply, reduces installation time, and minimizes disruption to ongoing operations.

It’s especially effective in large-scale environments where installing individual ceiling tiles or wall panels would be both time-consuming and expensive. With professional-grade spray equipment, entire surfaces can be covered in a fraction of the time, without compromising on coverage or performance.

Superior Acoustic Performance

When it comes to managing noise in industrial environments, performance is king. Acoustic Spray excels in reducing reverberation time—the measure of how long sound lingers in a space after the source stops.

Studies show that high reverberation times lead to increased stress levels, miscommunication, and even hearing loss in extreme environments. Acoustic Spray can reduce reverberation by absorbing sound waves at the source, leading to better speech intelligibility, safer work environments, and improved operational efficiency.

Thermal and Environmental Benefits

Beyond sound absorption, many types of Acoustic Spray also offer thermal insulation properties, helping regulate indoor temperature in large-scale structures. This dual functionality is especially beneficial in warehouses, distribution centers, and industrial workshops, where maintaining a consistent internal temperature can be challenging.

Additionally, the sustainability factor cannot be ignored. Many Acoustic Spray products are made from recycled content, low-VOC components, and can contribute to green certification. That makes them a popular choice for designers focused on eco-conscious building strategies.

Safety and Fire Resistance

In industrial environments, fire safety is a critical concern. Many Acoustic Spray products come with Class A fire ratings, offering peace of mind to facility managers and safety inspectors. The seamless nature of the application also eliminates the risk of loose tiles or sagging panels—common issues in older industrial settings.

Cost-Effectiveness in the Long Run

While the upfront cost of Acoustic Spray might be higher than some panel-based alternatives, the total cost of ownership is significantly lower over time. It requires less maintenance, is durable, and retains its acoustic properties for years. There's no need for frequent replacements or touch-ups, making it an ideal long-term solution for large facilities.

Retrofit-Friendly for Existing Buildings

Many industrial design projects involve renovating older buildings—often with concrete ceilings, steel structures, and open ductwork. Traditional acoustic systems struggle to adapt to these unique geometries, but Acoustic Spray shines here.

Its ability to conform to existing structures without major modifications makes it the perfect choice for retrofitting legacy buildings without compromising on design intent or acoustic needs.

Endorsement by Design and Acoustic Professionals

Finally, the rise of Acoustic Spray can be attributed to its growing endorsement by leading architects, designers, and acousticians. As word spreads about its success in enhancing both function and aesthetics, it’s rapidly becoming a go-to solution in the industrial design toolbox.

Whether it's an innovation lab, a production floor, or a multi-use industrial space, professionals now understand that acoustic quality isn't optional—it’s essential.

Conclusion

Industrial design is undergoing a transformation, and Acoustic Spray is right at the center of it. Its rise in popularity is no fluke—it addresses real challenges with smart, adaptable, and design-friendly solutions.

As spaces continue to grow in scale and complexity, the demand for performance-based design interventions will only increase. Acoustic Spray meets this demand head-on, offering a product that’s as practical as it is progressive.